Terene ea Terene ea BS Standard Steel Terene

literenee ka boela ea sebelisoa liketsahalong tse ling tse khethehileng, joalo ka literene tse tšesaane merafong, literene tse khethehileng lifekthering, jj. Ka kakaretso, literene tsa British Standard ke karolo ea bohlokoa ea tsamaiso ea lipalangoang tsa literene.

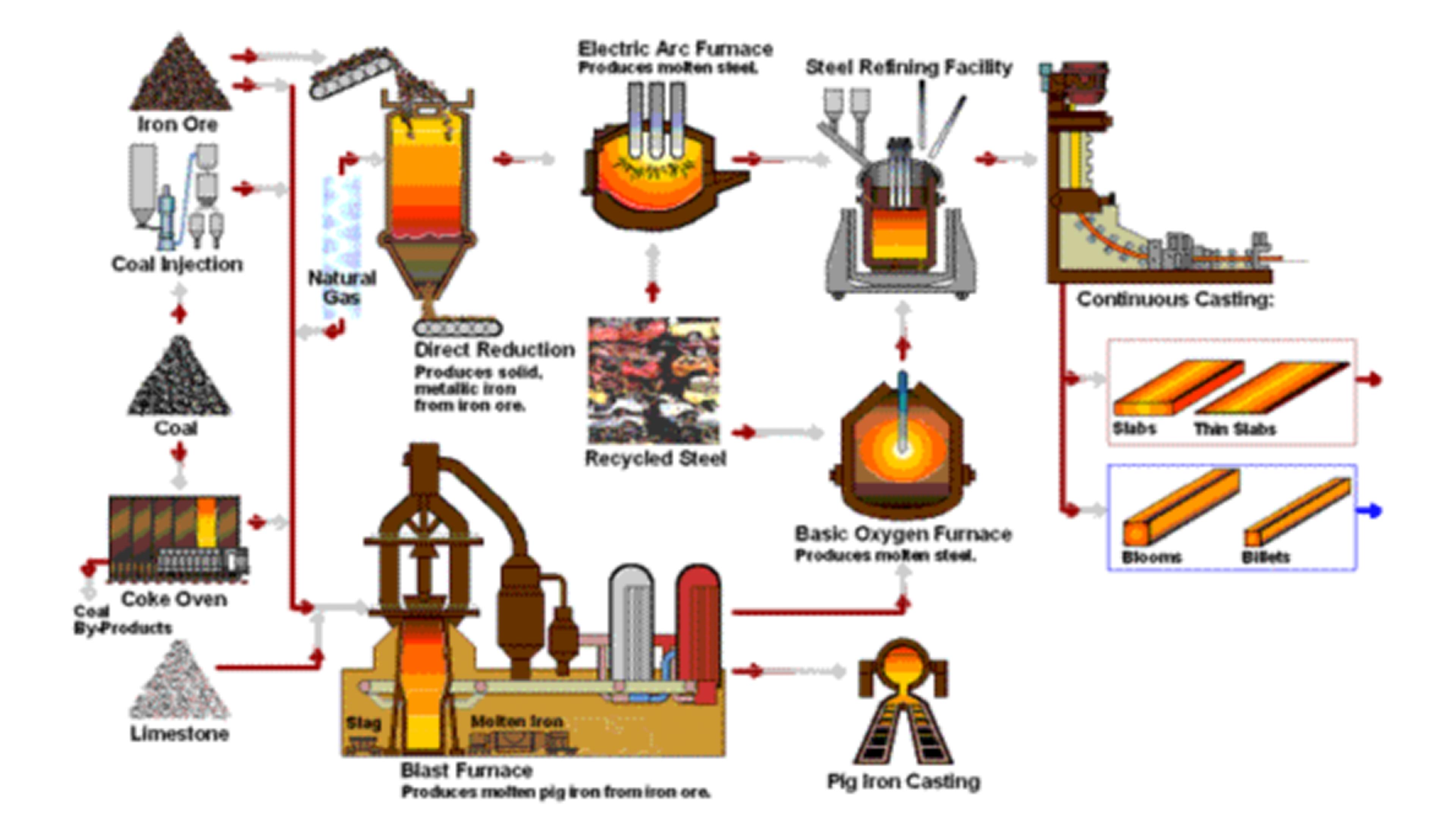

Mokhoa oa Tlhahiso ea Sehlahisoa

Ts'ebetso ea tlhahiso eaTerene ea Tšepe e Tloaelehileng ea BShangata e kenyelletsa mehato e latelang:

Tokiso ea thepa e tala: Lokisetsa thepa e tala bakeng sa tšepe, hangata tšepe ea sebopeho sa carbon ea boleng bo holimo kapa tšepe e nang le motsoako o tlase.

Ho qhibilihisa le ho lahla: Thepa e tala e qhibilihisoa, ebe tšepe e qhibilihisitsoeng e lahleloa ka har'a li-billet tsa tšepe tsa pele ka ho qhibilihisa kapa ho tšolla ho tsoelang pele.

Ho hlwekisa le ho phutholla: Ho hlwekisa billet ya tshepe ya pele, ho kenyeletswa le ho tlosa ditshila le ho lokisa motswako, ebe o phutholla billet ya tshepe ka hara disebediswa tse phuthollang ho di-billet tsa pina tse fihlelang maemo a naha.

Kalafo esale pele: Kalafo esale pele ea li-billet tsa literene, ho kenyeletsoa le forging, kalafo ea mocheso le kalafo ea bokaholimo, jj., ho ntlafatsa matla le ho tšoarella ha literene.

Ho pitikisa le ho bopa: Sekotwana sa terene se seng se phekotsoe esale pele se pitikisa le ho bopa ka mochini o pitikisang ho se etsa profil ea terene e fihlelang litlhoko tsa maemo a naha.

Tlhahlobo le taolo ea boleng: Tlhahlobo e tiileng le taolo ea boleng li etsoa litereneng tse hlahisitsoeng ho netefatsa hore li fihlela maemo a naha le litlhoko tsa bareki.

Ho paka le ho tsoa fekthering: Literene tse tšoanelehang lia pakoa le ho tšoauoa, ebe li isoa ho moreki kapa li bolokoa ka tlung ea polokelo li emetse ho romelloa.

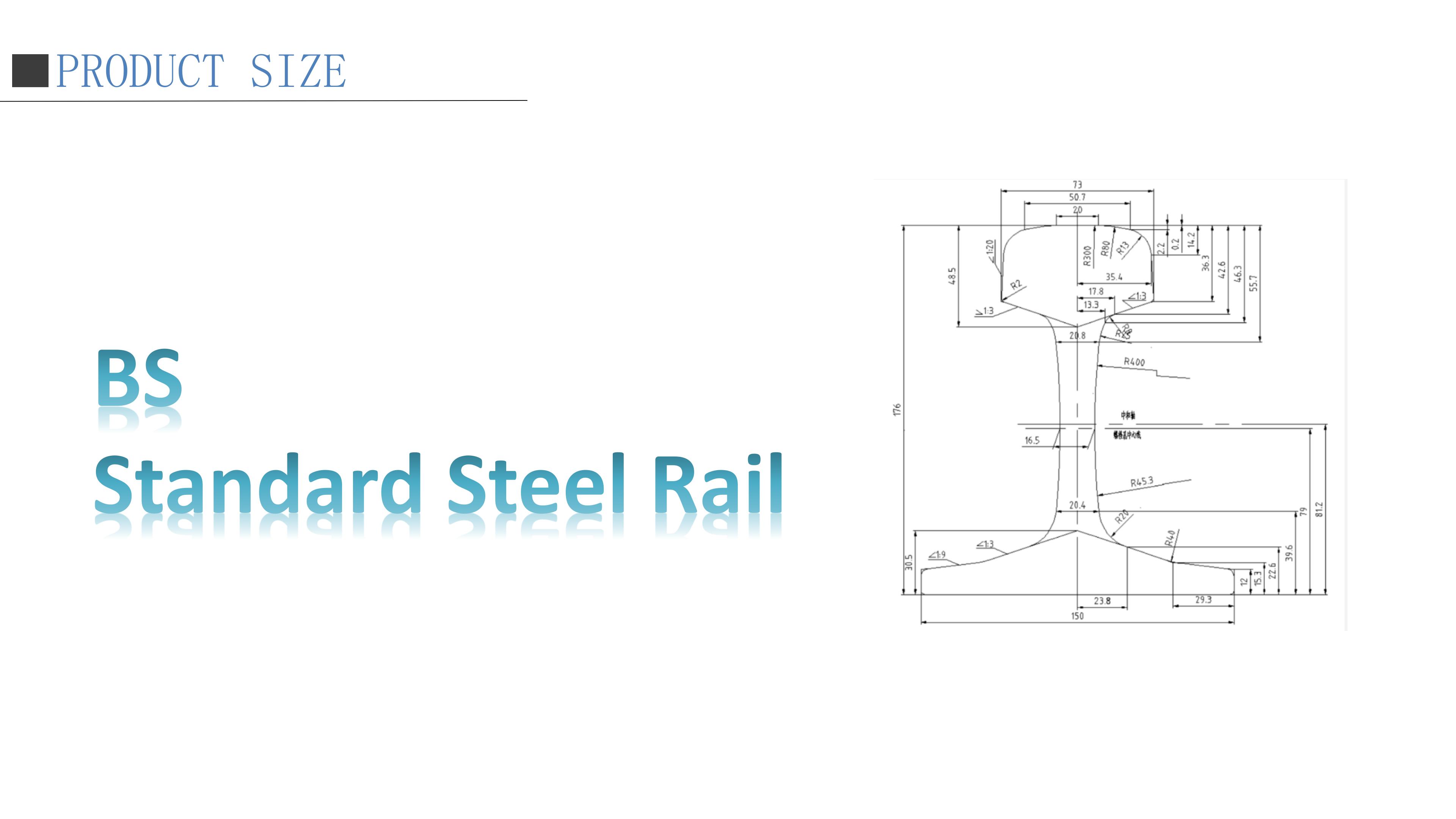

BOHOLO BA SEHLAHISOA

| BS11: Terene e tloaelehileng ea 1985 | |||||||

| mohlala | boholo (mm) | ntho | boleng ba thepa | bolelele | |||

| bophara ba hlooho | bophahamo | boto ea motheo | botebo ba letheka | (kg/m) | (m) | ||

| A(mm) | B(mm) | C(mm) | D(mm) | ||||

| 500 | 52.39 | 100.01 | 100.01 | 10.32 | 24.833 | 700 | 6-18 |

| 60 A | 57.15 | 114.3 | 109.54 | 11.11 | 30.618 | 900A | 6-18 |

| 60R | 57.15 | 114.3 | 109.54 | 11.11 | 29.822 | 700 | 6-18 |

| 70 A | 60.32 | 123.82 | 111.12 | 12.3 | 34.807 | 900A | 8-25 |

| 75 A | 61.91 | 128.59 | 14.3 | 12.7 | 37.455 | 900A | 8-25 |

| 75R | 61.91 | 128.59 | 122.24 | 13.1 | 37.041 | 900A | 8-25 |

| 80 A | 63.5 | 133.35 | 117.47 | 13.1 | 39.761 | 900A | 8-25 |

| 80 R | 63.5 | 133.35 | 127 | 13.49 | 39.674 | 900A | 8-25 |

| 90 A | 66.67 | 142.88 | 127 | 13.89 | 45.099 | 900A | 8-25 |

| 100A | 69.85 | 152.4 | 133.35 | 15.08 | 50.182 | 900A | 8-25 |

| 113A | 69.85 | 158.75 | 139.7 | 20 | 56.398 | 900A | 8-25 |

Terene ea tšepe e tloaelehileng ea BS:

Litlhaloso: BS50O, BS60A, BS60R, BS70A, BS75A, BS75R, BS80A, BS80R, BS90A, BS100A, BS113A

Tekanyetso: BS11-1985

Thepa: 700/900A

Bolelele: 6-18m 8-25m

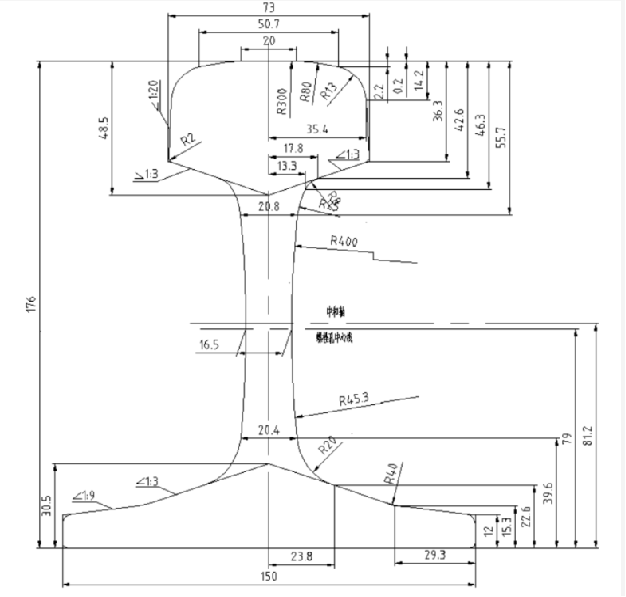

MORERO

Khamphani ea rona'lithane tse 13,800 tsaSeporo sa Terene sea rekisoaLi-romello tse rometsoeng United States li ile tsa romeloa Koung ea Tianjin ka nako e le 'ngoe. Morero oa kaho o phethiloe ka terene ea ho qetela e ntseng e beoa butle-butle moleng oa terene. Li-romello tsena kaofela li tsoa moleng oa tlhahiso oa lefats'e oa fektheri ea rona ea literene le mahlakore a tšepe, ho sebelisoa lefats'e ka bophara. E hlahisitsoe ka maemo a tekheniki a holimo le a thata ka ho fetisisa.

Bakeng sa tlhahisoleseling e batsi ka lihlahisoa tsa terene, ka kopo ikopanye le rona!

WeChat: +86 13652091506

Mohala: +86 13652091506

Imeile:[email protected]

MOLEMO

tšepe ea terenetse nang le matla a maholo le bokgoni ba ho jara mojaro mme di ka mamella boima le kgatello ya tshebetso ya terene.

Ho hanyetsa ho tsofala: Bokaholimo ba seporo bo sebedisitswe ka ho kgetheha ho ntlafatsa ho hanyetsa ho tsofala ha sona, ho eketsa nako ya tshebeletso ya sona le ho fokotsa ditjeo tsa tlhokomelo.

Thibelo ea ho bola: Karolo e ka holimo ea seporo e ka phekoloa ka thibelo ea ho bola ho ntlafatsa ho hanyetsa ha eona ho bola le ho ikamahanya le maemo a fapaneng a tikoloho, haholo-holo bakeng sa ho tšoarella hamolemo libakeng tse mongobo kapa tse senyang.

Ho latela Maemo: Ho latela Maemo a Brithani ho netefatsa boleng le polokeho ea seporo, e leng se etsang hore se lokele litsamaiso tsa literene ka hare ho UK.

Ho Tšepahala: Literene tse tloaelehileng tsa Brithani li laoloa ka thata boleng 'me li na le ts'ebetso e tsitsitseng le boleng bo tšepahalang, ho netefatsa ts'ebetso e sireletsehileng le e tsitsitseng ea sistimi ea terene.

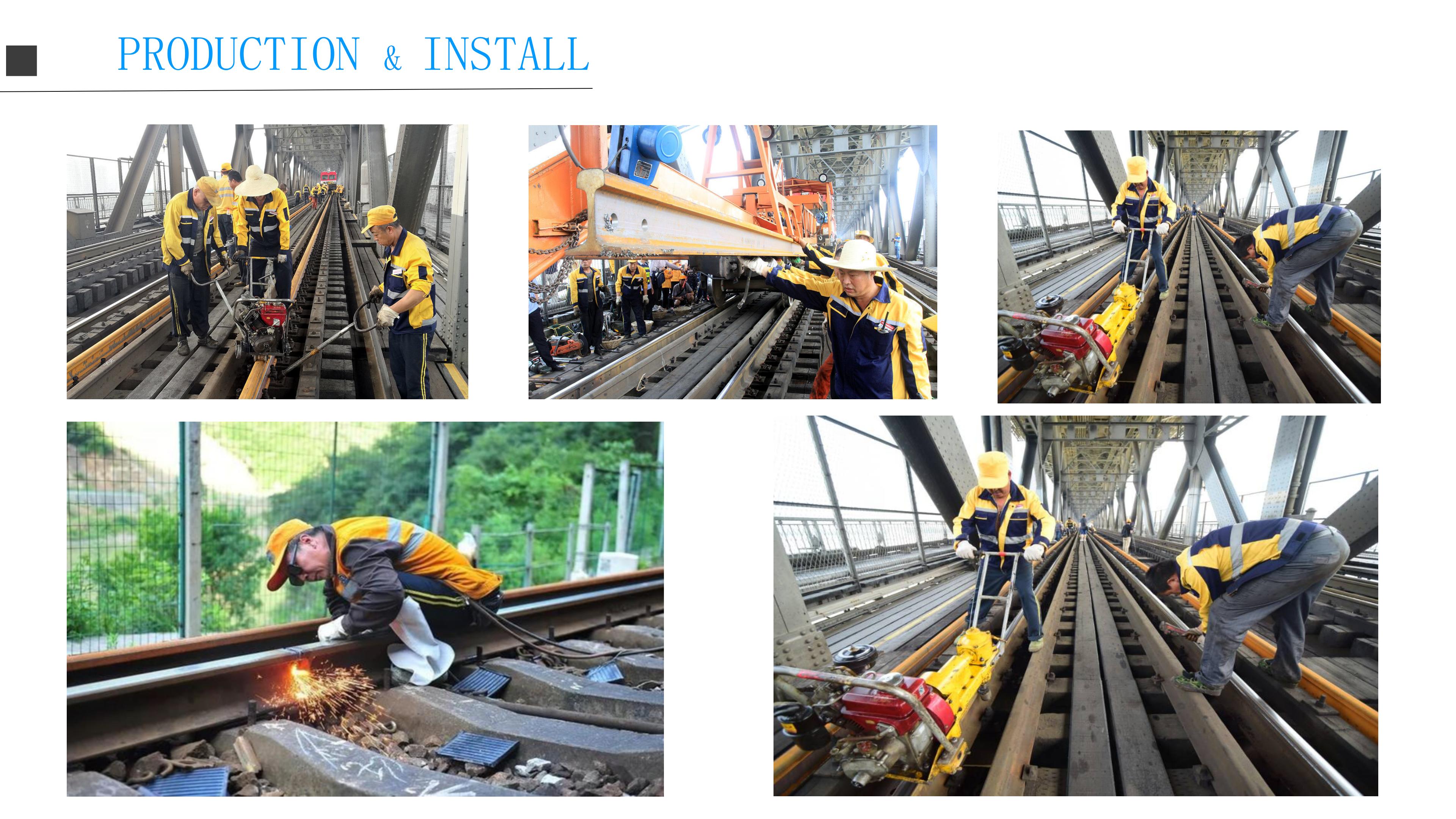

KOPO

Literene tse tloaelehileng tsa Brithani li sebelisoa haholo-holo litsamaisong tsa literene e le litselana tseo literene li ka tsamaeang ho tsona. Li jara boima ba terene, li fana ka tsela e tsitsitseng, 'me li netefatsa hore terene e ka sebetsa ka mokhoa o sireletsehileng le o sebetsang hantle. Literene tse tloaelehileng tsa Brithani hangata li entsoe ka tšepe e matla haholo 'me li khona ho mamella khatello e boima le tšebeliso e tsoelang pele, kahoo li bapala karolo ea bohlokoa lipalangoangng tsa literene.

Ntle le tsamaiso e kholo ea literene, literene tse tloaelehileng tsa Brithani li ka boela tsa sebelisoa liketsahalong tse ling tse khethehileng, joalo ka literene tse nang le tekanyo e nyane merafong, literene tse khethehileng lifekthering, jj.

Ka kakaretso, literene tse tloaelehileng tsa Brithani ke karolo ea bohlokoa ea tsamaiso ea lipalangoang tsa terene. Li fana ka litsela tsa ho khanna tse sireletsehileng le tse tsitsitseng bakeng sa literene 'me ke meralo ea motheo ea bohlokoa lefapheng la lipalangoang tsa Brithani.

HO PHAKISA LE HO ROMELA

Hangata literei tse tloaelehileng li phutheloa ka litsela tse latelang:

Ho kopanya: Hangata literene li tlamelloa ka lithapo tsa tšepe kapa thapo ea terata ho netefatsa hore ha li sisinyehe kapa ha li senyehe nakong ea lipalangoang. Sena se thusa ho boloka sebopeho le botšepehi ba literene.

Litšepe tsa mapolanka: Litšepe tsa mapolanka hangata li eketsoa lipheletsong tsa lireile ho thibela ho kopana ho senya tsela le ho fana ka tšehetso le tšireletso e eketsehileng.

Boitsebiso: Litlhaloso, mohlala, letsatsi la tlhahiso le tlhahisoleseling e 'ngoe ea terene hangata li tšoailoe sephutheloana ho nolofatsa boitsebiso le tsamaiso.

Mekhoa ena ea ho paka e thusa ho netefatsa hore literene ha li senyehe nakong ea lipalangoang le polokelo 'me li isoa ka mokhoa o sireletsehileng moo li eang teng.

KAHO EA SEBAKA

E entsoe Chaena, tšebeletso ea boemo ba pele, boleng bo holimo, e tsebahala lefatšeng ka bophara

1. Phello ea sekala: Khamphani ea rona e na le ketane e kholo ea phepelo le fektheri e kholo ea tšepe, e fihlelang liphello tse kholo lipalangoang le theko, 'me e fetoha k'hamphani ea tšepe e kopanyang tlhahiso le lits'ebeletso.

2. Mefutafuta ya dihlahiswa: Mefutafuta ya dihlahiswa, tshepe efe kapa efe eo o e batlang e ka rekwa ho rona, haholo-holo e sebetsanang le meaho ya tshepe, di-rails tsa tshepe, di-sheet pile tsa tshepe, di-bracket tsa photovoltaic, tshepe ya kanale, di-coil tsa tshepe tsa silicon le dihlahiswa tse ding, e leng se etsang hore e tenyetsehe haholoanyane. Khetha mofuta wa sehlahiswa o lakatsehang ho fihlela ditlhoko tse fapaneng.

3. Phepelo e tsitsitseng: Ho ba le mohala o tsitsitseng oa tlhahiso le ketane ea phepelo ho ka fana ka phepelo e tšepahalang haholoanyane. Sena se bohlokoa haholo ho bareki ba hlokang tšepe e ngata.

4. Tšusumetso ea lets'oao: E na le tšusumetso e phahameng ea lets'oao le 'maraka o moholo

5. Tšebeletso: Khamphani e kholo ea tšepe e kopanyang mokhoa oa ho iketsetsa, lipalangoang le tlhahiso

6. Tlholisano ea theko: theko e utloahalang

*Romella imeile ho[email protected]ho fumana khotheishene bakeng sa merero ea hau

KETO EA BAREKI

LBH

LBH

1. Nka fumana khotheishene joang ho tsoa ho uena?

O ka re siela molaetsa, 'me re tla araba molaetsa o mong le o mong ka nako.

2. Na o tla isa thepa ka nako?

E, re tšepisa ho fana ka lihlahisoa tsa boleng bo holimo le ho li tlisa ka nako. Botšepehi ke molao-motheo oa k'hamphani ea rona.

3.Na nka fumana disampole pele ke odara?

E, ehlile. Hangata disampole tsa rona ha di lefellwe, re ka di hlahisa ka disampole tsa hao kapa ka ditshwantsho tsa botekgeniki.

4. Lipehelo tsa hau tsa tefo ke life?

Nako ea rona ea tefo e tloaelehileng ke depositi ea 30%, 'me karolo e setseng khahlanong le B/L. EXW, FOB, CFR, CIF.

5. Na o amohela tlhahlobo ea motho oa boraro?

E, ruri rea amohela.

6. Re tšepa khamphani ea hau joang?

Re ikhethile khoebong ea tšepe ka lilemo tse ngata re le mofani oa khauta, ntlo-kholo e profinseng ea Tianjin, re amohelehile ho etsa lipatlisiso ka litsela life kapa life, ka mekhoa eohle.