Terene ea Terene ea Terene ea Tšepe e Tloaelehileng ea GB Theko ea Fektheri Terene ea Tšepe e Matla le e Tšoarellang e Loketse Kaho le Tse Ling

Ka kutloisiso e itseng,lihlahisoa tsa terene tse ngatantshetsopele le yona ke nalane ya ntshetsopele ya diterene. Ntle le ntshetsopele ya theknoloji ya diterene, theknoloji ya diterene tse boima le tse lebelo le hodimo e thata ho e ntshetsa pele. Boleng ba diterene bo na le tshusumetso ya bohlokwa polokehong le bokgoning ba dipalangwang tsa diterene.

Pele ho phetohelo ea indasteri Europe, litselana li ne li entsoe ka mapolanka a malelele a bophara ba lisenthimithara tse 'maloa. Tlas'a tsela ea lehong, sengoathoana sa lehong se ne se beoa ka ho rapama maotong a mabeli ho isa ho a mararo e le li-robala. Li-robala li ne li sebelisoa haholo ho lokisa tsela ea lehong e le hore e boloke bophara bo boletsoeng. Mabili a mathang ka holim'a eona le 'ona a ne a entsoe ka lehong. Ka nako eo, tšepe e ne e ke ke ea hlahisoa ka tekanyo e kholo, 'me tšepe le eona e ne e le thepa e turang haholo. Tsela ea lehong e ne e le bonolo ho e robeha le ho e taboha. Hamorao, batho ba ne ba khomaretsa maqephe a masesaane a tšepe holim'a eona 'me ba a tiisa ka lipekere. Tseleng, sena ha se lelefatse feela bophelo ba tšebeletso ea tsela, empa hape se fokotsa ho hanyetsa ho hohlana, e leng seporo sa khale ka ho fetisisa.

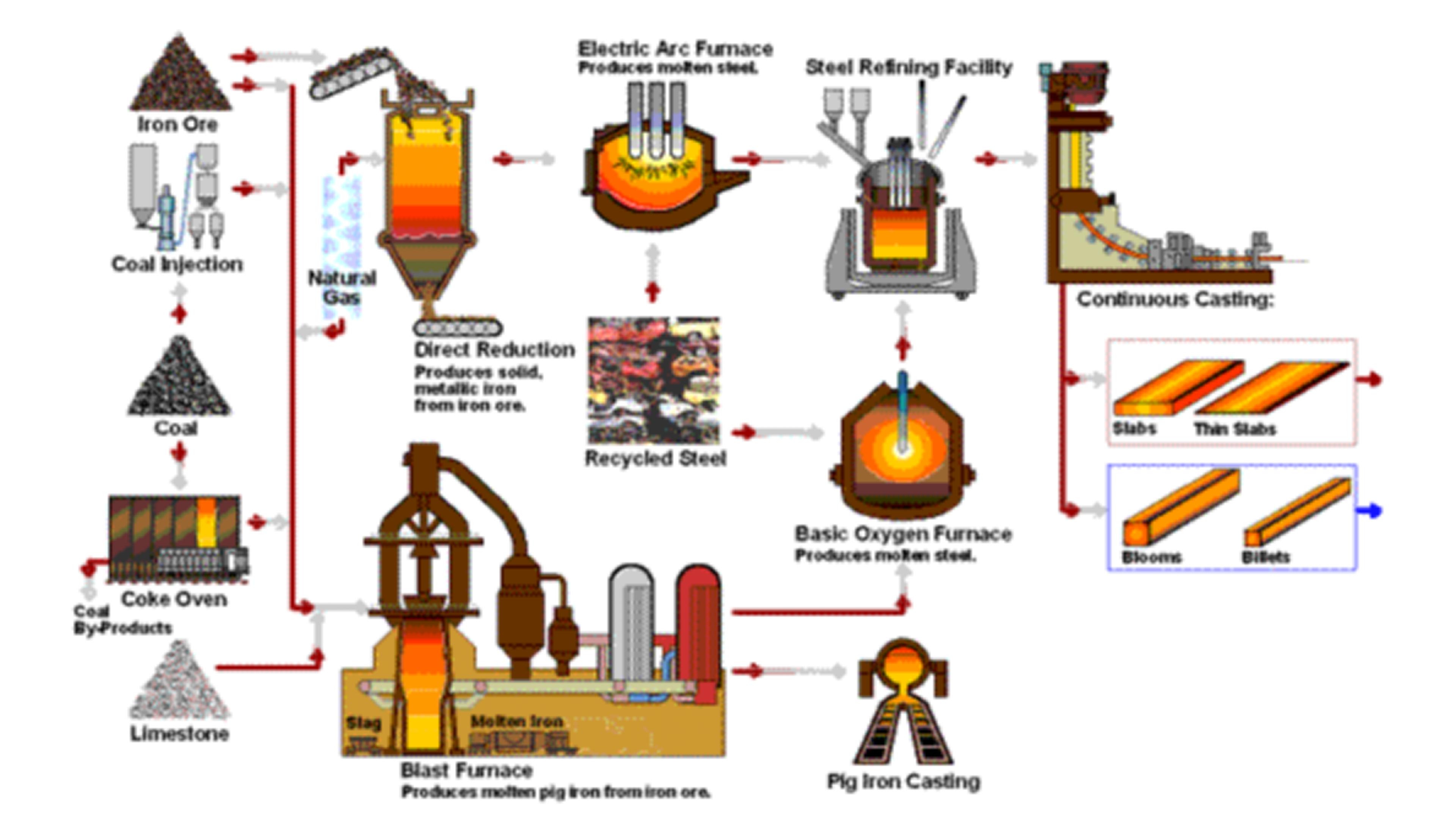

Mokhoa oa Tlhahiso ea Sehlahisoa

Theknoloji le Ts'ebetso ea Kaho

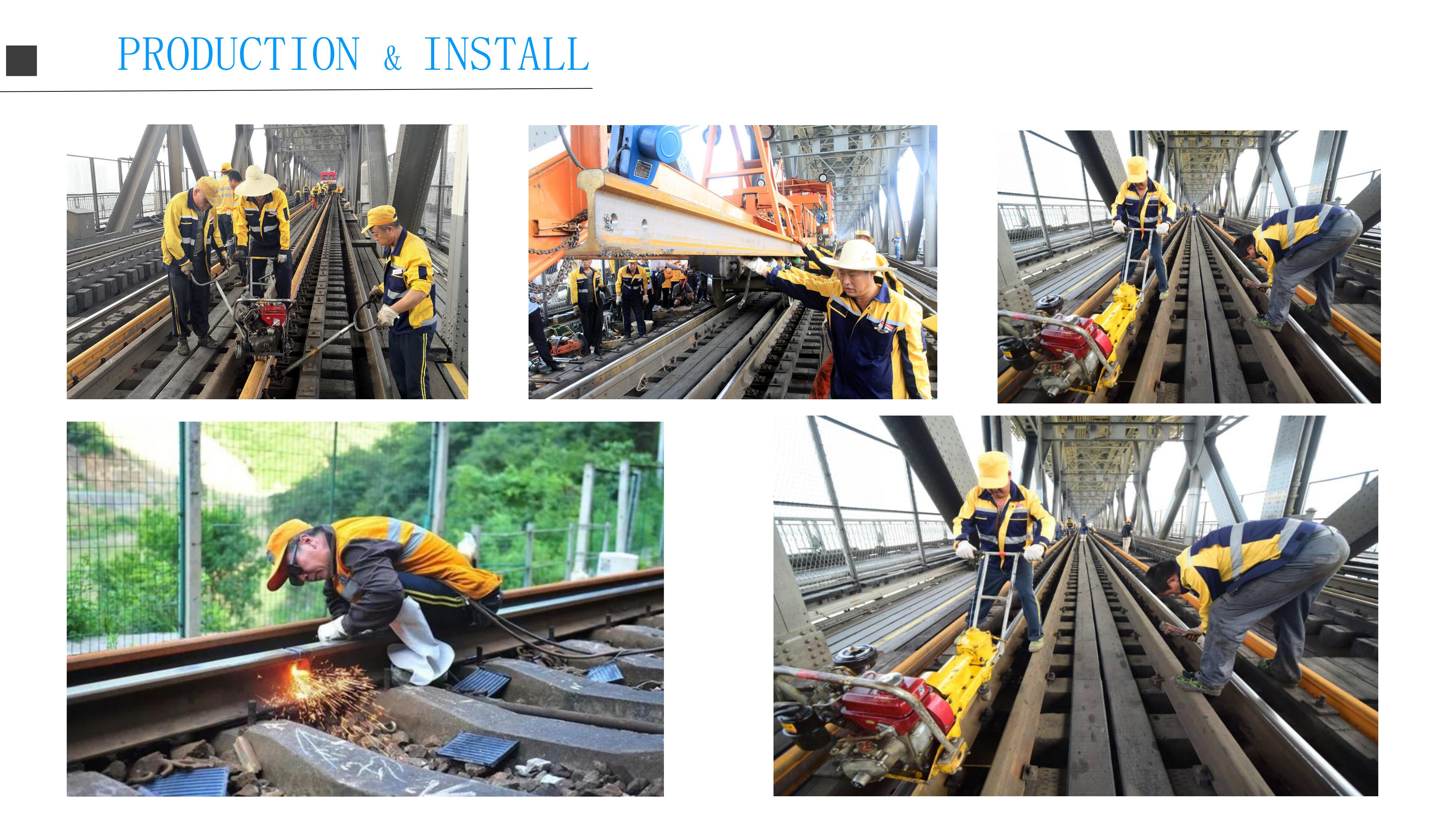

Mokhoa oa ho hahaLitsela tsa Terene ea TereneLiterata li kenyelletsa boenjiniere bo nepahetseng le ho nahana ka hloko ka lintlha tse fapaneng. E qala ka ho rala moralo oa literata, ho nahanoa ka tšebeliso e reriloeng, lebelo la terene le sebaka. Hang ha moralo o phethetsoe, ts'ebetso ea kaho e qala ka mehato ea bohlokoa e latelang:

1. Ho Epa le Motheo: Sehlopha sa kaho se lokisa mobu ka ho epa sebaka seo le ho theha motheo o tiileng ho tshehetsa boima le kgatello e bakwang ke diterene.

2. Ho Kenya Ballast: Lera la lejoe le pshatlehileng, le tsejoang e le ballast, le beoa holim'a bokaholimo bo lokisitsoeng. Sena se sebetsa e le lera le monyang ho thothomela, le fanang ka botsitso, le ho thusa ho aba mojaro ka ho lekana.

3. Lithapo le ho Tiisa: Lithapo tsa lehong kapa tsa konkreite li kenngoa holim'a ballast, li etsisa sebopeho se kang foreimi. Lithapo tsena li fana ka motheo o sireletsehileng bakeng sa litsela tsa terene tsa tšepe. Li tlamelloa ka ho sebelisa li-spikes kapa li-clip tse itseng, ho netefatsa hore li lula li tiile sebakeng sa tsona.

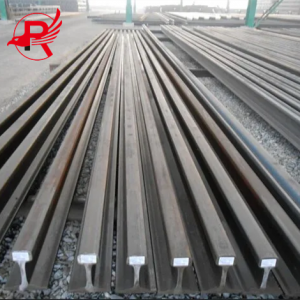

4. Ho Kenya Terene: Literene tsa tšepe tsa 10m, tse atisang ho bitsoa literene tse tloaelehileng, li behiloe ka hloko holim'a lithapo. Kaha li entsoe ka tšepe ea boleng bo holimo, litsela tsena li na le matla a makatsang le ho tšoarella.

Mofuta le matla aTšepe ea Terene ea Tereneli hlahisoa ka boima bo hakanyetsoang (lik'hilograma) ka bolelele ba mithara. Mohlala, mefuta ea literene tse tloaelehileng tsa hona joale Chaena ke 43kg/m, 50kg/m, 60kg/m, 75kg/m, jj. Bolelele bo tloaelehileng ba literene Chaena: 43kg/m ke 12.5m kapa 25m; bolelele ba literene tse ka holimo ho 50kg/m ke 25m, 50m, le 100m. E-ea fekthering ea ho tjheseletsa literene ho e tjheseletsa ka seporo se bolelele ba 500m, ebe u e isa sebakeng sa kaho ebe u e tjheseletsa ka bolelele bo hlokahalang.

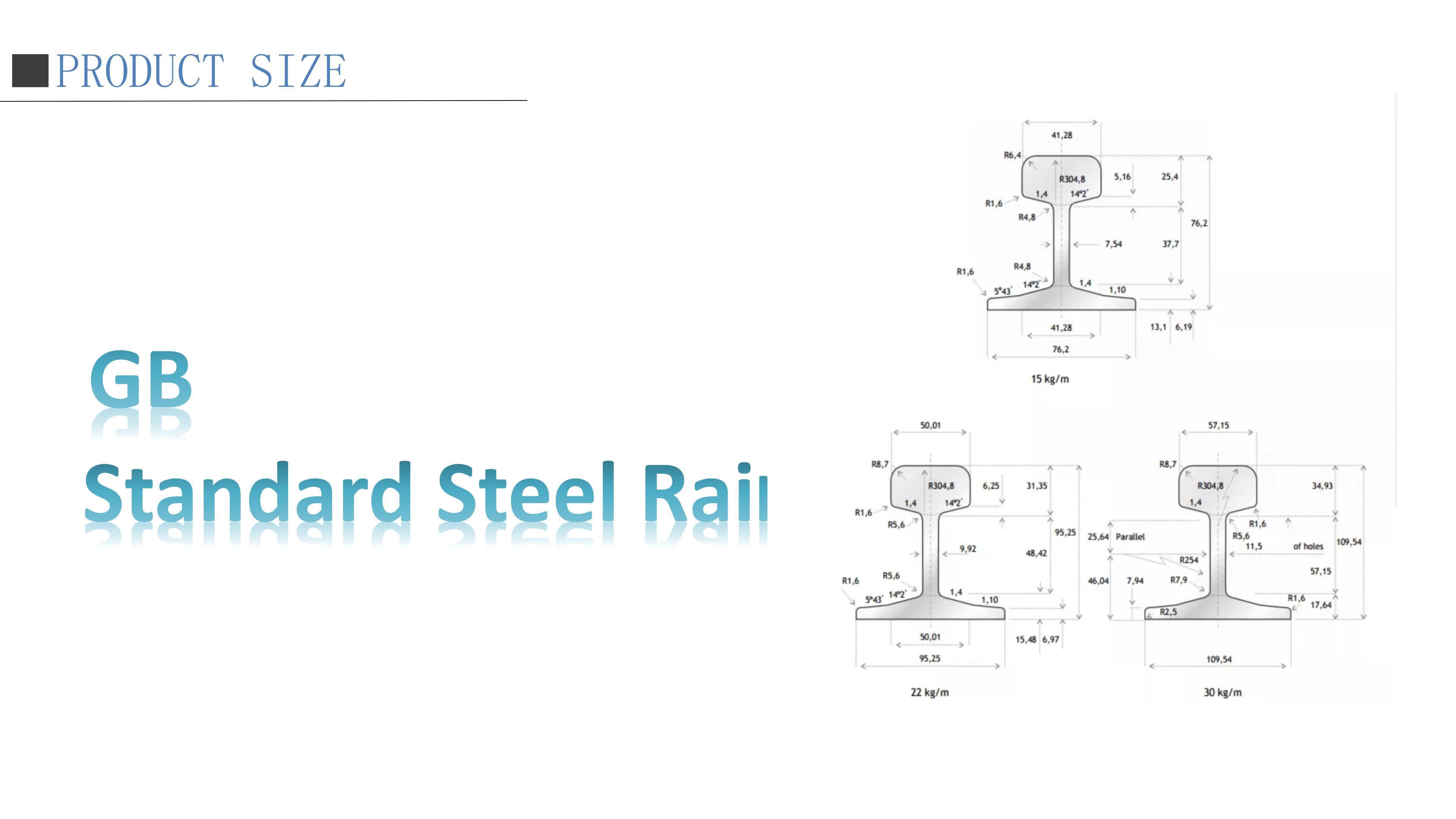

BOHOLO BA SEHLAHISOA

| Lebitso la Sehlahisoa: | Terene ea Tšepe e Tloaelehileng ea GB | |||

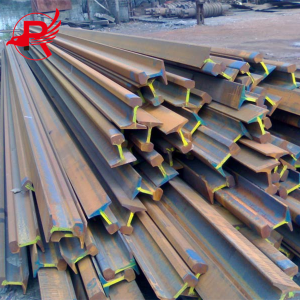

| Mofuta: | Terene e Boima, Terene ea Crane, Terene e Bobebe | |||

| Boitsebiso/Tlhaloso: | ||||

| Terene e bobebe: | Mohlala/Thepa: | Q235, 55Q ; | Tlhaloso: | 30kg/m,24kg/m,22kg/m,18kg/m,15kg/m,12 kg/m,8 kg/m. |

| Terene e Boima: | Mohlala/Thepa: | 45MN, 71MN; | Tlhaloso: | 50kg/m,43kg/m,38kg/m,33kg/m. |

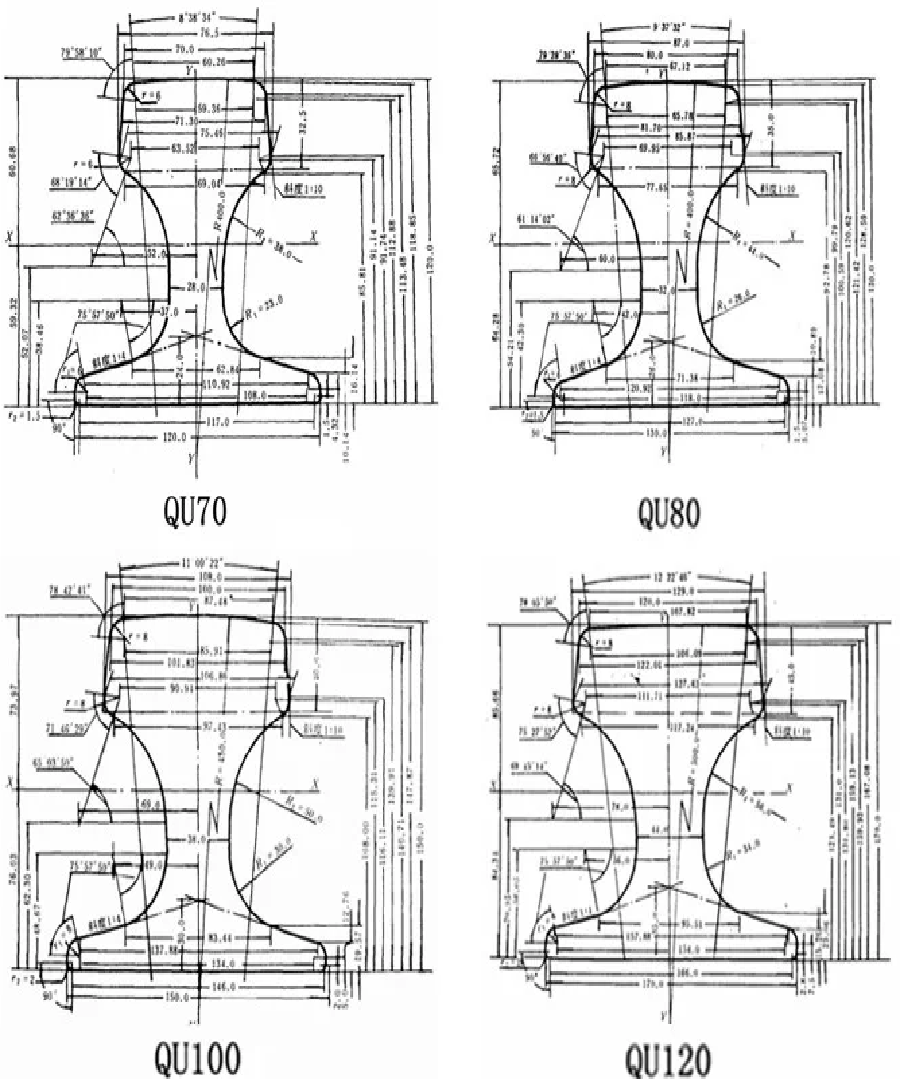

| Terene ea Crane: | Mohlala/Thepa: | U71MN; | Tlhaloso: | QU70 kg /m ,QU80 kg /m ,QU100kg /m ,QU120 kg /m . |

Terene e tloaelehileng ea naha:

Litlhaloso: GB6kg, 8kg, GB9kg, GB12, GB15kg, 18kg, GB22kg, 24kg, GB30, P38kg, P43kg, P50kg, P60kg, QU70, QU80, QU100, QU120

Tekanyetso: GB11264-89 GB2585-2007 YB/T5055-93

Thepa: U71Mn/50Mn

Bolelele: 6m-12m 12.5m-25m

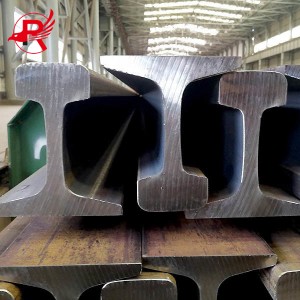

| Thepa | Sehlopha | Boholo ba Karolo (mm) | ||||

| Bophahamo ba Terene | Bophara ba Motheo | Bophara ba Hlooho | Botenya | Boima (lik'hilograma) | ||

| Terene e Nyenyane | 8KG/M | 65.00 | 54.00 | 25.00 | 7.00 | 8.42 |

| 12KG/M | 69.85 | 69.85 | 38.10 | 7.54 | 12.2 | |

| 15KG/M | 79.37 | 79.37 | 42.86 | 8.33 | 15.2 | |

| 18KG/M | 90.00 | 80.00 | 40.00 | 10.00 | 18.06 | |

| 22KG/M | 93.66 | 93.66 | 50.80 | 10.72 | 22.3 | |

| 24KG/M | 107.95 | 92.00 | 51.00 | 10.90 | 24.46 | |

| 30KG/M | 107.95 | 107.95 | 60.33 | 12.30 | 30.10 | |

| Terene e Boima | 38KG/M | 134.00 | 114.00 | 68.00 | 13.00 | 38.733 |

| 43KG/M | 140.00 | 114.00 | 70.00 | 14.50 | 44.653 | |

| 50KG/M | 152.00 | 132.00 | 70.00 | 15.50 | 51.514 | |

| 60KG/M | 176.00 | 150.00 | 75.00 | 20.00 | 74.64 | |

| 75KG/M | 192.00 | 150.00 | 75.00 | 20.00 | 74.64 | |

| UIC54 | 159.00 | 140.00 | 70.00 | 16.00 | 54.43 | |

| UIC60 | 172.00 | 150.00 | 74.30 | 16.50 | 60.21 | |

| Terene ea ho Phahamisa | QU70 | 120.00 | 120.00 | 70.00 | 28.00 | 52.80 |

| QU80 | 130.00 | 130.00 | 80.00 | 32.00 | 63.69 | |

| QU100 | 150.00 | 150.00 | 100.00 | 38.00 | 88.96 | |

| QU120 | 170.00 | 170.00 | 120.00 | 44.00 | 118.1 | |

MOLEMO

Ha o kgethaTsela ea Terene ea Tšepe,o hloka ho nahana ka lintlha tse latelang:

1. Thepa: Thepa ea thepa ea terene ke ntlha ea bohlokoa e amang ts'ebetso ea eona le bophelo ba ts'ebeletso. Thepa e sebelisoang hangata ke tšepe ea khabone le tšepe e nang le motsoako o tlase.

2. Boholo: Boholo ba seporo ke ntlha ea bohlokoa ha ho khethoa seporo. Litsela le likoloi tse fapaneng li hloka boholo bo fapaneng ba liporo.

3. Boleng: Boleng ba literene bo ama ka kotloloho polokeho ea ts'ebetso le bophelo ba ts'ebeletso ea lipalangoang tsa terene. Ha u khetha literene, u lokela ho khetha lihlahisoa tsa boleng bo holimo tse fihlelang litlhoko tsa hau.

4. Bokgoni ba ho bea: Ha o kgetha ditereila, o hloka ho nahana hore na bokgoni ba ho bea di fihlella ditlhoko tsa hao. Ka tlwaelo, dintlha tse kang boima ba koloi, lebelo le boemo ba mola wa terene di hloka ho nahanelwa.

Literene tse tloaelehileng tsa naha li na le melemo e latelang:

1. Matla a phahameng, ho thatafala ho hoholo le ho hanyetsa ho tsofala hantle, ho kgona ho fihlela ditlhoko tsa tshebetso ya nako e telele ya matla a hodimo.

2. E na le khanyetso e ntle ea mokhathala 'me e ka mamella moroalo o pheta-phetoang ntle le ho ba le tšekamelo ea ho hloleha ho khathala.

3. Ho hanyetsa mafome hantle, ho kgona ho hanela mafome a tswang dinthong tse fapaneng tsa dikhemikhale le ho lelefatsa nako ya tshebeletso.

4. Polokeho e phahameng, e ka netefatsang ts'ebetso e sireletsehileng ea lipalangoang tsa terene le ho fokotsa menyetla ea likotsi.

5. E na le bophelo bo bolelele ba tšebeletso 'me e ka finyella litlhoko tsa tšebeliso ea nako e telele ea lipalangoang tsa terene.

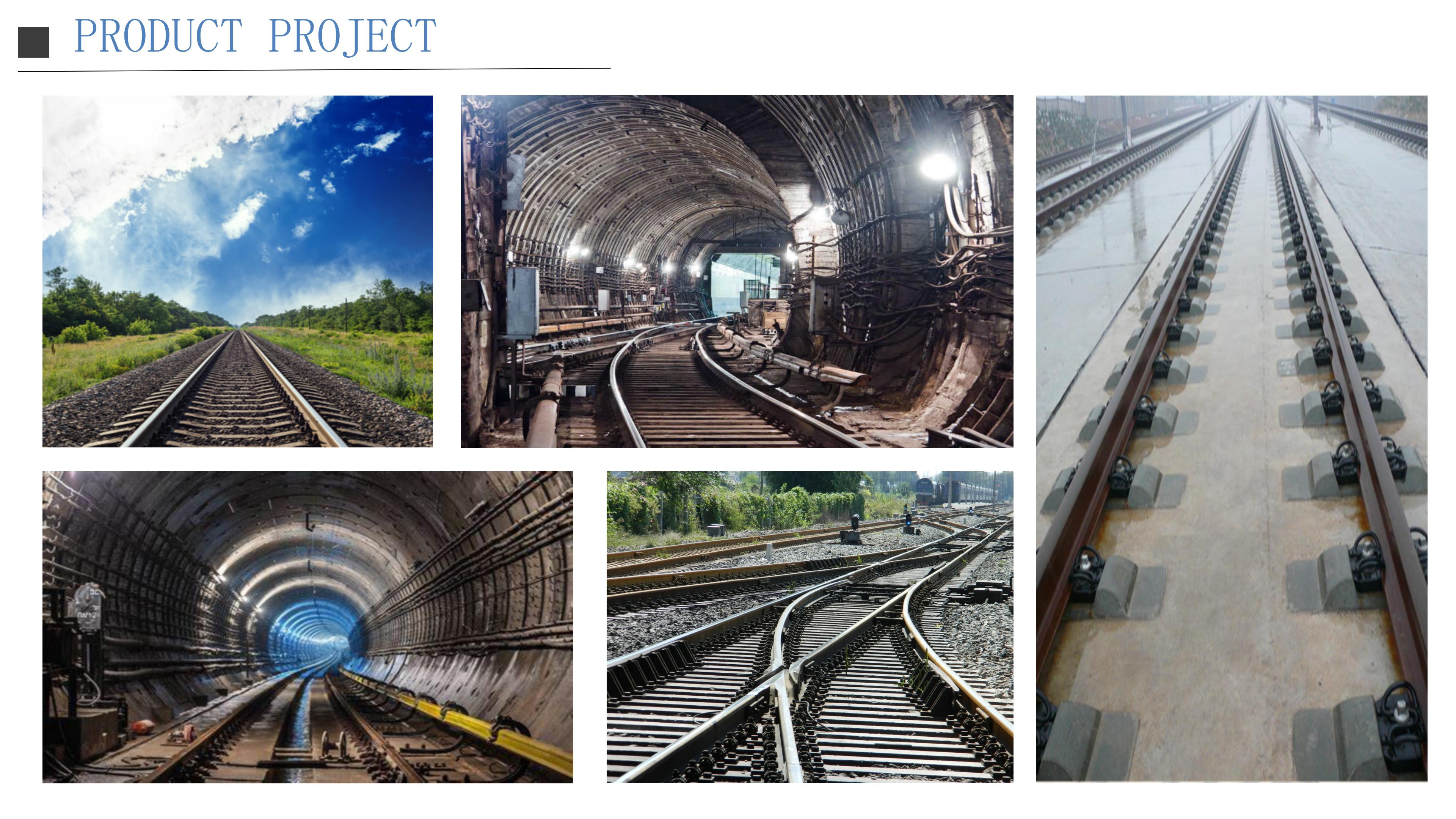

MORERO

Khamphani ea rona'Literene tsa tšepe tse boima ba lithane tse 13,800 tse rometsoeng United States li ile tsa romeloa Koung ea Tianjin ka nako e le 'ngoe. Morero oa kaho o phethiloe ka terene ea ho qetela e ntseng e beoa butle-butle moleng oa terene. Literene tsena kaofela li tsoa moleng oa tlhahiso oa lefats'e oa fektheri ea rona ea literene le mahlakore a tšepe, ho sebelisoa lefats'e ka bophara. E hlahisitsoe ka maemo a holimo le a thata ka ho fetisisa a tekheniki.

Bakeng sa tlhahisoleseling e batsi ka lihlahisoa tsa terene, ka kopo ikopanye le rona!

WeChat: +86 13652091506

Mohala: +86 13652091506

Imeile:[email protected]

KOPO

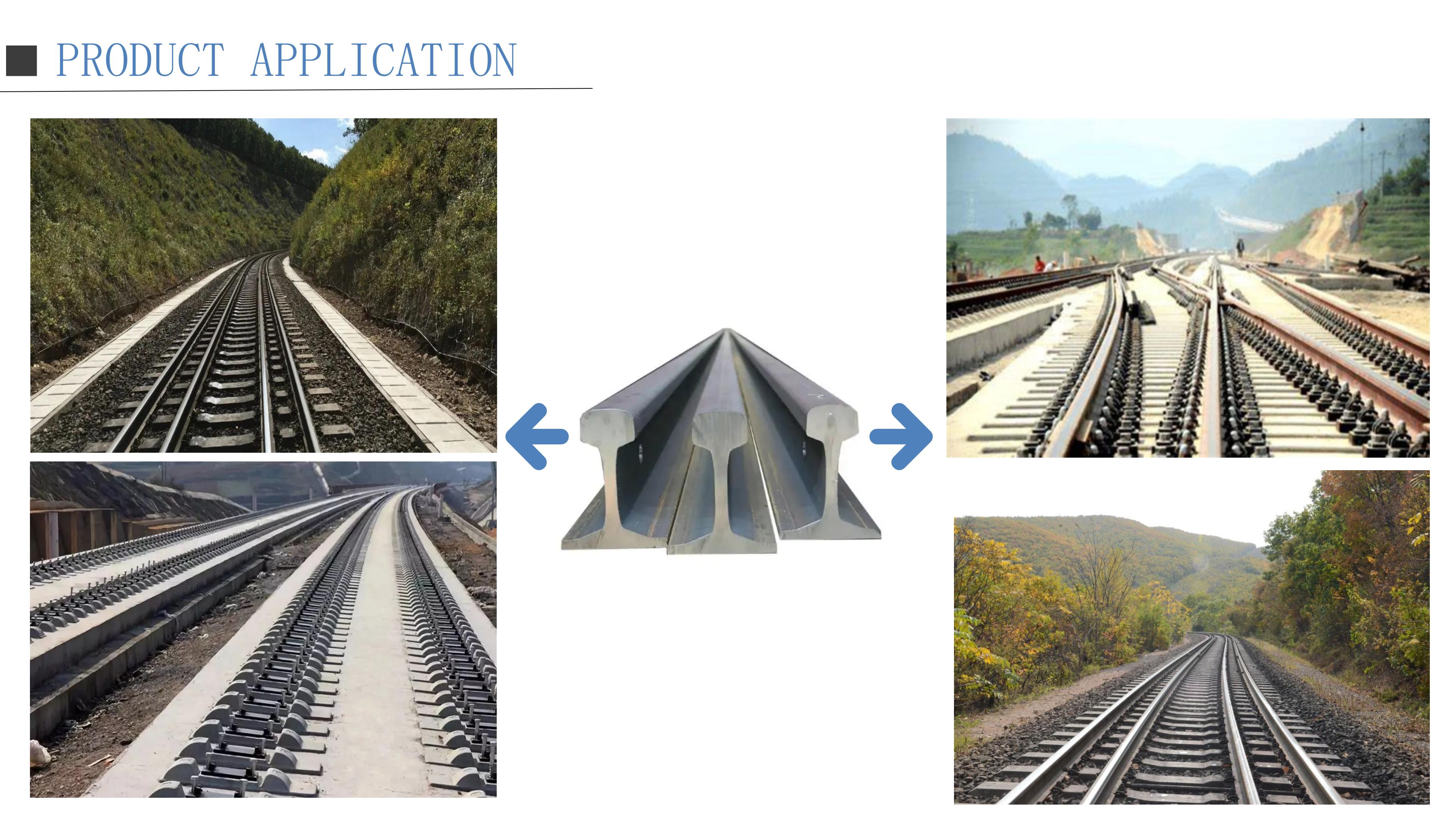

Terene ea SeporoMoralo oa karolo ea hlooho le oona ke e 'ngoe ea litsela tsa ho ntlafatsa ho satalla le ho hanyetsa ho tsofala.

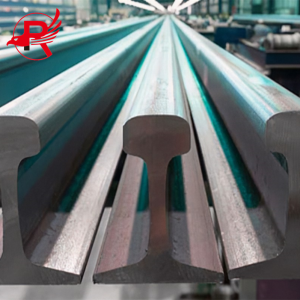

Karolong ea hlooho ea seporo sa pele sa terene, bokaholimo ba leoto bo bonolo haholo, 'me li-arcs tse nang le radius e nyane li sebelisoa mahlakoreng ka bobeli. Ho fihlela lilemong tsa bo-1950 le bo-1960, ho ile ha fumanoa hore ho sa tsotelehe sebōpeho sa hlooho ea seporo e neng e entsoe qalong, ka mor'a ho senyeha ha mabili a terene, sebopeho sa leoto le ka holimo ho terene se ne se batla se le chitja, 'me radius ea leoto mahlakoreng ka bobeli e ne e le khōlō haholo. Ketsiso ea liteko e fumane hore ho petsoha ha hlooho ea terene ho amana le khatello e feteletseng ea ho kopana ha lebili le seporo ka hare ho fillet ea hlooho ea terene. E le ho fokotsa tšenyo ea ho hlobola ha seporo, linaha tsohle li fetotse moralo oa leoto la hlooho ea terene ho fokotsa ho fetoha ha polasetiki.

Taba ea pele, linaha li latetse molao-motheo o joalo moralong oa treilara ea hlooho ea seporo: arc ea treilara ea holimo ea seporo e lumellana le boholo ba treilara ea lebili ka hohle kamoo ho ka khonehang, ke hore, boholo ba treilara ea seporo, joalo ka tereilara ea 59.9kg/m United States, arc ea hlooho ea seporo e amoheloa R254-R31.75-R9.52; tereilara ea 65kg/m ea Soviet Union ea mehleng, arc ea hlooho ea seporo e amohela R300-R80-R15; tereilara ea UIC ea 60kg/m, arc ea hlooho ea seporo e amohela R300-R80-R13. Ho ka bonoa ho tsoa ho se boletsoeng ka holimo hore tšobotsi e ka sehloohong ea moralo oa karolo ea tereilara ea sejoale-joale ke tšebeliso ea li-curve tse rarahaneng le li-radii tse tharo. Ka lehlakoreng la tereilara ea hlooho, ho amoheloa mola o otlolohileng o nang le top e moqotetsane le botlaase bo pharaletseng, 'me leralla la mola o otlolohileng ka kakaretso ke 1:20~1:40. Mohala o otlolohileng o nang le leralla le leholo o atisa ho sebelisoa mohlahareng o ka tlase oa hlooho ea seporo, 'me leralla ka kakaretso ke 1:3 ho isa ho 1:4.

Sa bobedi, sebakeng sa phetoho pakeng tsa hlooho ya seporo le letheka la seporo, e le ho fokotsa mapetso a bakwang ke kgatello ya maikutlo le ho eketsa khanyetso ya ho thulana pakeng tsa fishplate le seporo, moedi o rarahaneng o boetse o sebediswa sebakeng sa phetoho pakeng tsa hlooho ya seporo le letheka la seporo, mme moralo o moholo wa radius o amohelwa lethekeng. Mohlala, seporo sa UIC sa 60kg/m se sebedisa R7-R35-R120 sebakeng sa phetoho pakeng tsa hlooho ya seporo le letheka. Seporo sa Japane sa 60kg/m se sebedisa R19-R19-R500 sebakeng sa phetoho pakeng tsa hlooho ya seporo le letheka.

HO PHAKISA LE HO ROMELA

Sebakeng sa phetoho pakeng tsa letheka la terene le tlase la terene, e le ho fihlella phetoho e boreleli ea karolo, moralo o rarahaneng oa kobeho le oona oa amoheloa, 'me phetoho e butle-butle e hokahantsoe hantle le leralla la tlase la terene. Joalo ka terene ea UIC60kg/m, ke ho sebelisa R120-R35-R7. Terene ea 60kg/m ea Japane e sebelisa R500-R19. Terene ea 60kg/m ea Chaena e sebelisa R400-R20. Ho tsamaisoa ha literene tsa terene tse lebelo le phahameng ho hloka thuso ea lisebelisoa tsa lipalangoang tsa litsebi le lihlopha. Ka kakaretso, literene tsa terene tse lebelo le phahameng li tsamaisoa ka terene. Mehatong ea pele ea kaho ea terene e lebelo le phahameng ea lehae, lisebelisoa tse ling tsa bohlokoa le thepa li ne li hloka ho romelloa kantle ho naha. Ka nako eo, lipalangoang tsa moea e ne e le mokhoa o tloaelehileng oa lipalangoang. Leha ho le joalo, literene tsa terene tse lebelo le phahameng tse ntlafalitsoeng le ho etsoa ka boikemelo hangata li tsamaisoa ke terene ka boeona. Terene e 'ngoe le e 'ngoe e lebelo le phahameng e bolelele ba limithara tse ka bang 25 'me e boima ba lithane tse 30. Hangata ho hlokahala likariki tse peli ka pele le ka morao ho phethela ts'ebetso eohle ea lipalangoang. Ka hona, pele ho lipalangoang, ho hlokahala ho rera tsela ka hloko le ho hlahloba esale pele hore na kariki e fihlela litlhoko tsa lipalangoang ho netefatsa hore ha ho na tšenyo kapa likotsi tsa polokeho tse tla etsahala nakong ea lipalangoang.

MATLA A K'hamphani

E entsoe Chaena, tšebeletso ea boemo ba pele, boleng bo holimo, e tsebahala lefatšeng ka bophara

1. Phello ea sekala: Khamphani ea rona e na le ketane e kholo ea phepelo le fektheri e kholo ea tšepe, e fihlelang liphello tse kholo lipalangoang le theko, 'me e fetoha k'hamphani ea tšepe e kopanyang tlhahiso le lits'ebeletso.

2. Mefutafuta ya dihlahiswa: Mefutafuta ya dihlahiswa, tshepe efe kapa efe eo o e batlang e ka rekwa ho rona, haholo-holo e sebetsanang le meaho ya tshepe, di-rails tsa tshepe, di-sheet pile tsa tshepe, di-bracket tsa photovoltaic, tshepe ya kanale, di-coil tsa tshepe tsa silicon le dihlahiswa tse ding, e leng se etsang hore e tenyetsehe haholoanyane. Khetha mofuta wa sehlahiswa o lakatsehang ho fihlela ditlhoko tse fapaneng.

3. Phepelo e tsitsitseng: Ho ba le mohala o tsitsitseng oa tlhahiso le ketane ea phepelo ho ka fana ka phepelo e tšepahalang haholoanyane. Sena se bohlokoa haholo ho bareki ba hlokang tšepe e ngata.

4. Tšusumetso ea lets'oao: E na le tšusumetso e phahameng ea lets'oao le 'maraka o moholo

5. Tšebeletso: Khamphani e kholo ea tšepe e kopanyang mokhoa oa ho iketsetsa, lipalangoang le tlhahiso

6. Tlholisano ea theko: theko e utloahalang

*Romella imeile ho[email protected]ho fumana khotheishene bakeng sa merero ea hau

KETO EA BAREKI

LBH

1. Nka fumana khotheishene joang ho tsoa ho uena?

O ka re siela molaetsa, 'me re tla araba molaetsa o mong le o mong ka nako.

2. Na o tla isa thepa ka nako?

E, re tšepisa ho fana ka lihlahisoa tsa boleng bo holimo le ho li tlisa ka nako. Botšepehi ke molao-motheo oa k'hamphani ea rona.

3.Na nka fumana disampole pele ke odara?

E, ehlile. Hangata disampole tsa rona ha di lefellwe, re ka di hlahisa ka disampole tsa hao kapa ka ditshwantsho tsa botekgeniki.

4. Lipehelo tsa hau tsa tefo ke life?

Nako ea rona ea tefo e tloaelehileng ke depositi ea 30%, 'me karolo e setseng khahlanong le B/L. EXW, FOB, CFR, CIF.

5. Na o amohela tlhahlobo ea motho oa boraro?

E, ruri rea amohela.

6. Re tšepa khamphani ea hau joang?

Re ikhethile khoebong ea tšepe ka lilemo tse ngata re le mofani oa khauta, ntlo-kholo e profinseng ea Tianjin, re amohelehile ho etsa lipatlisiso ka litsela life kapa life, ka mekhoa eohle.