Lihlahisoa

-

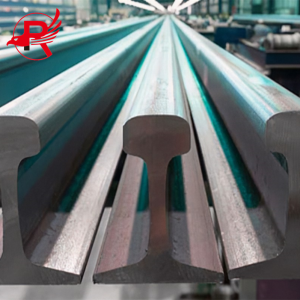

Likarolo tsa Terene ea Matla ea Crane ea Tšepe e Chesang e Felletseng e Felletseng ea GB e Felletseng

Terene ea tšepeke karolo e ka sehloohong ea seporo sa terene. Mosebetsi oa sona ke ho tataisa mabili a seporo se ntseng se bilikana ho ea pele, ho mamella khatello e kholo ea mabili, le ho fetisetsa ho motho ea robalang. Seporo se tlameha ho fana ka sebaka se bilikanang se tsoelang pele, se boreleli, le se sa haneleng lebili. Karolong ea terene e nang le motlakase kapa ea block e iketsang, seporo se ka boela sa sebelisoa e le potoloho ea seporo.

-

Seporo sa Tšepe sa DIN 536 Crane A45 A55 A65 A75 A100 A120 A150 Seporo sa Tšepe se Tloaelehileng sa Crane

Thepa ea seporo ha se ea tšepe e tloaelehileng, ka kakaretso e sebelisa tšepe ea sebopeho sa carbon ea boleng bo holimo le tšepe e matla e nang le motsoako o tlase, e nang le matla a phahameng, khanyetso e phahameng ea ho tsofala, ho tiea ho phahameng le litšobotsi tse ling, ke tšehetso ea bohlokoa ho netefatsa polokeho le katleho ea lipalangoang tsa terene.

-

Terene ea Tšepe e Tloaelehileng ea DIN Terene e Tloaelehileng Terene ea Tšepe ea Carbon

Mekhoa ea literene e bile karolo ea bohlokoa ea tsoelo-pele ea batho ho tloha mathoasong a lekholo la bo19 la lilemo, e fetola lipalangoang le khoebo libakeng tse telele. Bohareng ba marang-rang ana a maholo ho na le mohale ea sa rorisoang: litsela tsa terene tsa tšepe. Ho kopanya matla, ho tšoarella le boenjiniere bo nepahetseng, litsela tsena li bapetse karolo ea bohlokoa ho bōpeng lefatše la rona la sejoale-joale.

-

Terene ea DIN ea Terene e Tloaelehileng ea Tšepe Theko e Boima ea Fektheri ea Literene tsa Boleng bo Botle ka ho Fetisisa Terene ea Tšepe ea Tsela

Terene ea Tšepe e Tloaelehileng ea DIN ke karolo ea bohlokoa ea lipalangoang tsa terene ho jara boima ba terene, 'me hape ke meralo ea motheo ea terene. E entsoe ka tšepe e matla haholo, e na le matla a matle le ho hanyetsa ho tsofala, 'me e ka mamella khatello e kholo le matla a ho thulana.

-

Litšebeletso tsa ho Koba Tšepe ea Motlakase ea Silicon e Tloaelehileng ea GB ASTM bakeng sa Tšebeliso ea Enjene ea ho Seha Lia Fumaneha

Likhoele tsa tšepe tsa silicon li sebelisoa haholo liindastering tse fapaneng ka lebaka la thepa ea tsona e ntle ea makenete. Leha ho le joalo, likhoele tsena li tla ka mefuta e fapaneng, e 'ngoe le e 'ngoe e loketse lits'ebetso tse itseng. Ka ho utloisisa likarolo le ts'ebeliso ea e 'ngoe le e 'ngoe, u ka etsa liqeto tse nang le tsebo ha u khetha khoele ea tšepe ea silicon e nepahetseng bakeng sa litlhoko tsa hau tse ikhethileng.

-

Khoele/Strip/Sheet ea Tšepe ea Lamination ea GB Standard Silicon, Tšepe ea Relay le Tšepe ea Transformer

Likhoele tsa tšepe tsa silicon tseo re motlotlo ka tsona li na le conductivity e phahameng haholo ea makenete le litšobotsi tse tlase tsa tahlehelo. Har'a tsona, taolo e nepahetseng ea litaba tsa silicon e etsa hore lakane ea tšepe ea silicon e be le matla a maholo a ho kenya makenete le tahlehelo e tlase ea hona joale ea eddy, ka hona e fokotsa tahlehelo ea matla nakong ea ts'ebetso ea lisebelisoa, 'me phello ea poloko ea matla le phokotso ea mosi e makatsa. Ho phaella moo, khoele ea tšepe ea silicon e boetse e bontša ts'ebetso e ntle ea ho phunya le ts'ebetso ea ho tjheseletsa, e leng se etsang hore ts'ebetso e be bonolo le e sebetsang hantle, e fihlela litlhoko tsa indasteri ea sejoale-joale bakeng sa lisebelisoa tse sebetsang hantle, tse bolokang matla le tsa tšireletso ea tikoloho.

-

50w600 50w800 50w1300 e sa shebaneng le thollo le induction e batang ea makenete e phutholohileng GB Koili e tloaelehileng ea tšepe ea silicon ea motlakase

Tahlehelo ea motheo ea tšepe ea silicon (e bitsoang tahlehelo ea tšepe) le matla a tlhahiso ea makenete (e bitsoang tlhahiso ea makenete) e le boleng ba tiisetso ea makenete ea sehlahisoa. Tahlehelo e tlase ea tšepe ea silicon e ka boloka motlakase o mongata, ea eketsa nako ea ts'ebetso ea lienjene le li-transformer le ho nolofatsa sistimi ea ho pholisa. Tahlehelo ea matla e bakoang ke tšenyo ea tšepe ea silicon e etsa 2.5% ~ 4.5% ea tlhahiso ea motlakase ea selemo le selemo, eo tahlehelo ea tšepe ea transformer e etsang hoo e ka bang 50%, 1 ~ 100kW e nyane e etsa hoo e ka bang 30%, 'me ballast ea lebone la fluorescent e etsa hoo e ka bang 15%.

-

Methapo ea Tšepe ea Motlakase ea GB e Ratang e Ikemiselitsoeng ea Silicon Steel Crgo Bakeng sa Phetoho ea Magnetic Ei Iron Core

Koili ea tšepe ea silicon ke thepa ea makenete e bobebe, e lerata le tlase, e sebetsang hantle haholo e entsoeng ka poleiti ea tšepe ea silicon ea motlakase. Ka lebaka la sebopeho se ikhethang le theknoloji ea ts'ebetso ea koili ea tšepe ea silicon, e na le ho kenella ho hoholo, tahlehelo e tlase ea tšepe le matla a tlase a ho kenngoa ha makenete, e leng se etsang hore e sebelisoe haholo indastering ea motlakase.

-

Litheko tsa Khoele ea Sheet Coil ea Tšepe ea Silicon e Tloaelehileng ea GB e Ratang e Oriented Crgo

Tšepe ea silicon e bolela motsoako o bonolo oa makenete oa Fe-Si, o tsejoang hape e le tšepe ea motlakase. Peresente ea boima ba tšepe ea silicon Si ke 0.4% ~ 6.5%. E na le ho kenella ho phahameng ha makenete, boleng bo tlase ba tahlehelo ea tšepe, thepa e ntle ea makenete, tahlehelo e tlase ea mantlha, matla a phahameng a ho kenya makenete, ts'ebetso e ntle ea ho phunya, boleng bo botle ba poleiti ea tšepe, le ts'ebetso e ntle ea filimi ea ho futhumatsa. jj..

-

Mefuta e sa tšoaneng ea Sebopeho sa Tšepe e na le Kaho e Ikhethang ea Theko

Sebopeho sa tšepe Ho phaella moo, ho na le sistimi ya sebopeho sa tshepe ya mabone a borokho e hanelang mocheso. Moaho ka bowona ha o boloke matla hantle. Theknoloji ena e sebedisa dihokelo tse ikgethang tse bohlale ho rarolla bothata ba marokho a batang le a chesang mohahong. Sebopeho se senyenyane sa truss se dumella dithapo le diphaephe tsa metsi ho feta leboteng bakeng sa kaho. Mokhabiso o bonolo.

-

Ho Welding ea Maqhubu a Phahameng Q235H Sebopeho sa Tšepe ea Tšepe Mesebetsi ea Kaho Tšepe ea Karolo e Betliloeng

Sebopeho sa tšepeke sebopeho sa boenjiniere se entsoeng ka ho sebetsana, ho hokahanya le ho kenya lipoleiti tsa tšepe, tšepe e chitja, liphaephe tsa tšepe, likhoele tsa tšepe le mefuta e fapaneng ea tšepe. Meaho ea tšepe e hloka ho mamella litlamorao tse fapaneng tsa tlhaho le tse entsoeng ke motho tikolohong 'me ke mehaho le meaho ea boenjiniere e nang le ts'epo e lekaneng le melemo e metle ea sechaba le moruo.

-

Terene ea Terene ea Boleng ba Tšepe ea DIN HMS /HMS 1 le 2, Litsela tsa Terene ka Terene e Kholo

Jwalo ka sebopeho se seholo se tshehetsang hoterenelipalangoang, bokgoni ba ho jara ba terene bo bohlokwa haholo. Ka lehlakoreng le leng, DIN Standard Steel Rail e hloka ho mamella boima le tshusumetso ya terene, mme ha ho bonolo ho e fetola le ho e robeha; Ka lehlakoreng le leng, tlasa terene e potlakileng e tswelang pele, ho hlokahala ho netefatsa botsitso le botshepehi ba terene. Ka hona, karolo ya mantlha ya terene ke matla a phahameng ho netefatsa polokeho ya terene.