Lihlahisoa

-

Kaho ea Pile ea Lithapo tsa Tšepe tse Chesang tse Chesang, Boleng bo Ikhethang ba Meaho e Phahameng

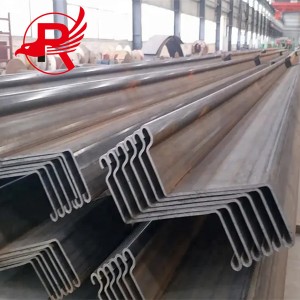

Qubu ea tšepe ke mofuta oa thepa ea meralo ea motheo, e simolohile Europe lekholong la bo20 la lilemo, 'me e sebelisoa ka potlako libakeng tsohle tsa indasteri ea kaho. E sebelisoa hangata libakeng tse fapaneng tsa mosebetsi tse metsi, ho kenyeletsoa likoung, libaka tsa ho koalla likepe, mabota a ho sireletsa, mehaho e ka tlas'a lefatše, jj. Ehlile, ka phetoho ea The Times, mefuta e fapaneng ea ts'ebeliso ea liqubu tsa tšepe e pharaletse haholo.

-

Lebota la ASTM Az36 A572 6m-12m 400X100 500X200 600X360 Lebota la Pile ea Lesela la Tšepe ea Khabone le Chesitsoeng ka Moqomo o Chesang

Ha ho tluoa tabeng ea poleloanaqubu ea lakane ea tšepe, Ke lumela hore ha re tloaelane haholo, empa ena ke e 'ngoe ea lintho tsa bohlokoa ka ho fetisisa morerong oa rona oa kaho, e tlisitseng thuso e kholo ntlafatsong ea indasteri ea rona ea kaho.

-

Moetsi oa Sechaena oa Sheet Pile ea Hot U Moetsi oa Sechaena oa Sheet Piling e Sebelisitsoeng ea Tšepe e Rekisoang

Ka ntlafatso ea meralo ea motheo ea linaha tse ling le nts'etsopele e potlakileng ea mefuta e fapaneng ea merero, kaho ealiqubu tsa tšepee sebelisitsoe mehahong e mengata, ebang ke mehaho ea kamehla, kapa mehaho ea nakoana, haholo-holo kaho ea mabota a bolokang metsi le mabota a bolokang metsi mererong ea meralo ea motheo ea masepala e ntse e eketseha khafetsa.

-

Li-Sheet tsa Tšepe tse Chesitsoeng tsa China Profil ea China Mofuta oa 2 Mofuta oa 3 Li-Sheet tsa Tšepe

Qhobosheane ea tšepeJwalo ka mofuta wa sebopeho se tshehetsang, se na le matla a hodimo, boima bo bobebe, ho kwahela metsi hantle, bophelo bo bolelele ba tshebeletso, polokeho e hodimo, ditlhoko tse tlase tsa sebaka, tshireletso ya tikoloho le dibopeho tse ding, empa hape se na le mosebetsi wa ho thusa nakong ya dikoduwa, hammoho le kaho e bonolo, nako e kgutshwane, e ka sebediswang hape, ditjeo tse tlase tsa kaho le tse ding, kahoo tshebediso ya qubu ya tshepe e pharaletse haholo.

-

Tšepe ea Angle ASTM Carbon E lekanang le Tšepe ea Angle Tšepe ea Tšepe Sebopeho se Bonolo Tšepe ea Angle Bar

Tšepe ea angle, e tsejoang haholo e le tšepe ea sekhutlo, ke tšepe e telele e nang le mahlakore a mabeli a otlolohileng. Ho na le tšepe ea sekhutlo e lekanang le tšepe ea sekhutlo e sa lekanang. Bophara ba mahlakore a mabeli a tšepe ea sekhutlo e lekanang bo lekana. Tlhaloso e hlalosoa ka mm ea bophara ba lehlakore × bophara ba lehlakore × botenya ba lehlakore. Joalo ka "∟ 30 × 30 × 3″, ke hore, tšepe ea sekhutlo e lekanang le bophara ba lehlakore ba 30mm le botenya ba lehlakore ba 3mm. E ka boela ea hlalosoa ka mohlala. Mohlala ke lisenthimithara tsa bophara ba lehlakore, joalo ka ∟ 3 × 3. Mohlala ha o emele litekanyo tsa botenya bo fapaneng ba lehlakore mohlaleng o tšoanang, kahoo bophara ba lehlakore le botenya ba lehlakore ba tšepe ea sekhutlo bo tla tlatsoa ka botlalo konterakeng le litokomaneng tse ling ho qoba ho sebelisa mohlala feela. Tlhaloso ea tšepe ea sekhutlo e lekanang le leoto e phutholohileng ke 2 × 3-20 × 3.

-

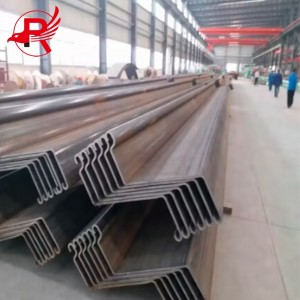

Sheet ea tšepe ea Larsen e phutholohileng e chesang ea mofuta oa PZ, e nang le liqubu tsa tšepe, e rekisoang ka bongata.

Qhobosheane ea tšepeke mofuta oa thepa ea boenjiniere ea motheo e matla haholo, e tšoarellang, e ka sebelisoang hape, e sebelisoang haholo boenjiniere ba sechaba, boenjiniere ba paballo ea metsi, kaho ea litsela tse kholo, kaho le meralo ea motheo ea litoropo le masimo a mang.

-

Pile ea Pipe ea Tšepe ea Z ea Boleng bo Holimo ea Cold Shape Sy295 400×100

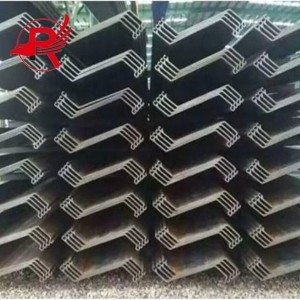

Liqubu tsa tšepeke mofuta oa tšepe e nang le senotlolo, karolo ea eona e na le sebopeho se otlolohileng sa poleiti, sebopeho sa mokoti le sebopeho sa Z, jj., ho na le boholo bo fapaneng le mefuta e hokelanang. Tse tloaelehileng ke setaele sa Larsen, setaele sa Lackawanna le tse ling. Melemo ea eona ke: matla a phahameng, ho bonolo ho kenella mobung o thata; Kaho e ka etsoa ka metsing a tebileng, 'me litšehetso tse otlolohileng lia eketsoa ho etsa lesaka haeba ho hlokahala. Tshebetso e ntle ea ho se kenelle metsi; E ka etsoa ho latela litlhoko tsa libopeho tse fapaneng tsa cofferdams, 'me e ka sebelisoa hape ka makhetlo a mangata, kahoo e na le mefuta e mengata ea ts'ebeliso.

-

Moetsi oa Liqubu tsa Lipampiri tsa Tšepe e Batang Sy295 Mofuta oa 2 Mofuta oa 3 Liqubu tsa Lipampiri tsa Tšepe tsa Z tse Ikhethileng

Qhobosheane ea tšepe e na le mefuta e mengata ea ts'ebeliso ho tsa tlhokomelo ea metsi, kaho, jeoloji, lipalangoang le masimo a mang.

-

Lifate tsa H tsa Fektheri tsa Chaena ASTM A36 A572 Hot Rolled H Karolo e Khabisitsoeng ea Tšepe ea H Kholomo e teng Setokong

HEAke mofuta oa tšepe e nang le sebopeho se tšekaletseng se tšoanang le tlhaku ea Senyesemane "H", e tsejoang hape e le sephara sa I-flange, lehlaseli la tšepe la bokahohleng kapa lehlaseli la I-flange le tšoanang.

-

Mofani oa Thekiso e Chesang ea Q355b Low Alloy 16mn S275jr 152X152 Low Carbon Steel e bōpehileng joaloka H Tšepe e Chesang e bōpehileng joaloka H

Litšobotsi tsaTšepe e bōpehileng joaloka HHaholo-holo e kenyelletsa matla a phahameng, botsitso bo botle le ho hanyetsa ho kobeha ho babatsehang. Karolo ea eona e tšekaletseng e bōpehile joaloka "H", e ka hasanyang matla ka katleho 'me e loketse mehaho e jarang meroalo e meholo. Ts'ebetso ea tlhahiso ea tšepe e bōpehileng joaloka H e etsa hore e be le ho tjheseletsa le ho sebetsa hantle haholoanyane, 'me e nolofatsa kaho ea sebakeng seo. Ho phaella moo, tšepe e bōpehileng joaloka H e bobebe ka boima 'me e matla haholo, e leng se ka fokotsang boima ba moaho le ho ntlafatsa moruo le polokeho ea moaho. E sebelisoa haholo masimong a kang kaho, marokho le tlhahiso ea mechini, 'me e fetohile thepa ea bohlokoa boenjiniere ba sejoale-joale.

-

H Beam ASTM A36 Hot Rolled Welding Universal Beam Q235B Q345E I Beam 16Mn Channel Steel Galvanized H Steel Structure Steel

Litšobotsi tsaTšepe e bōpehileng joaloka HHaholo-holo e kenyelletsa matla a phahameng, botsitso bo botle le ho hanyetsa ho kobeha ho babatsehang. Karolo ea eona e tšekaletseng e bōpehile joaloka "H", e ka hasanyang matla ka katleho 'me e loketse mehaho e jarang meroalo e meholo. Ts'ebetso ea tlhahiso ea tšepe e bōpehileng joaloka H e etsa hore e be le ho tjheseletsa le ho sebetsa hantle haholoanyane, 'me e nolofatsa kaho ea sebakeng seo. Ho phaella moo, tšepe e bōpehileng joaloka H e bobebe ka boima 'me e matla haholo, e leng se ka fokotsang boima ba moaho le ho ntlafatsa moruo le polokeho ea moaho. E sebelisoa haholo masimong a kang kaho, marokho le tlhahiso ea mechini, 'me e fetohile thepa ea bohlokoa boenjiniere ba sejoale-joale.

-

ASTM A36 HEA HEB IPE H Libalaka tsa I Libalaka tsa Moaho / Sebopeho sa Tšepe se bōpehileng joaloka H se nang le (St37-2) (USt37-2) (RSt37-2) A570 Gr.A Kereiti

Lehlaseli la HTšepe ea kanale ke mofuta oa tšepe e nang le karolo e tšekaletseng e bōpehileng joaloka tlhaku "H"; e nkoa e le profil ea tšepe ea sebopeho e theko e tlaase. E reheletsoe ka sebopeho sa eona sa "H". Ha e bapisoa le li-I-beams, li-H-beams li na le li-flange tse pharaletseng le marang-rang a masesaane, e leng se fellang ka ts'ebetso e ntle ea karolo e tšekaletseng, e li lumellang ho mamella meroalo e meholo ha li ntse li sebelisa thepa e nyane ea tšepe.