Lihlahisoa

-

Boleng bo Phahameng ba Leqephe la Sebopeho sa U SY295 400 × 100 la Leqephe la Tšepe

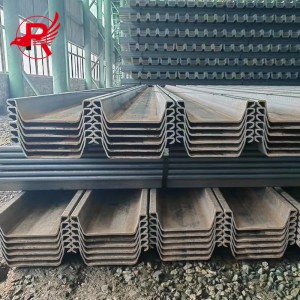

Tšepemabota a qubu ea maselali fetotse indasteri ea kaho ka matla a tsona a ikhethang, botsitso le ho tenyetseha. Ke tharollo e matla bakeng sa ho theha meaho e tšepahalang ea ho boloka mobu e tšehetsang ho epolloa, ho thibela khoholeho ea mobu, le ho fana ka botsitso mererong e fapaneng ea boenjiniere ba sechaba.

-

Pile ea Tšepe e Chesitsoeng ea Mofuta oa U SX10 SX18 SX27 bakeng sa Kaho

Ho bokella lakane ea tšepe ea mofuta oa U e phutholohileng ka tšepe e chesangke mofuta oa qubu ea tšepe e sebelisoang haholo mererong ea kaho le ea meralo ea motheo. E bōpehile joaloka U 'me e entsoe ka likhoele tsa tšepe tse phutholohang tse chesang. Mofuta ona oa qubu ea maqephe o tsejoa ka matla a oona a phahameng le ho tšoarella, e leng se etsang hore e lokele lits'ebetso tse hlokang mabota a tšoarellang, li-bulkhead le metheo ho mamella meroalo le likhatello tse phahameng. E fana ka khanyetso e ntle khahlanong le mafome, e leng se etsang hore e lokele le libaka tsa leoatle. Piling ea tšepe ea mofuta oa U e phutholohileng ka tšepe e chesang e fumaneha ka boholo, bolelele le limaraka tse fapaneng ho fihlela litlhoko tse itseng tsa projeke.

-

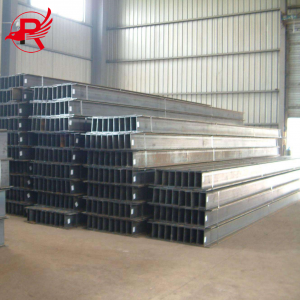

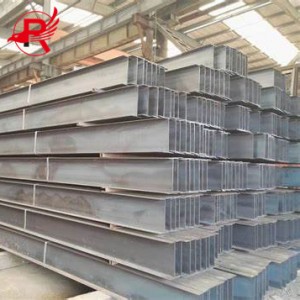

ASTM A572 S235jr Kereiti ea 50 150X150 W30X132 Sephara sa Flange Ipe 270 Ipe 300 Heb 260 Hea 200 Kaho ea H Beam

Flange e pharaletsengLehlaseli la Hke lehlaseli la tšepe la sebopeho le nang le lehlaseli le sephara le fanang ka matla le ho tšoarella ho eketsehileng. Hangata le sebelisoa mererong ea kaho le ea boenjiniere bakeng sa ho tšehetsa meroalo e boima le ho fana ka botsitso ba sebopeho. Sebopeho sa H sa lehlaseli se lumella ho tenyetseha ho hoholo lits'ebetsong tsa moralo le tsa kaho.

-

Mofuta oa Sheet ea Tšepe e Metsuoang e Chesang ea U S355GP

A Qhobosheane ea tšepe e bōpehileng joaloka Uke mofuta oa liqubu tsa tšepe tse nang le sebopeho se tšekaletseng se tšoanang le tlhaku "U". E sebelisoa hangata mererong ea boenjiniere ba sechaba le ea kaho bakeng sa lits'ebetso tse fapaneng, joalo ka mabota a ho boloka, li-cofferdams, tšehetso ea motheo le meaho ea lebopong la leoatle.

Lintlha tse qaqileng tsa qubu ea tšepe e bōpehileng joaloka U hangata li kenyelletsa litlhaloso tse latelang:

Litekanyo: Boholo le litekanyo tsa qubu ea tšepe, joalo ka bolelele, bophara le botenya, li boletsoe ho latela litlhoko tsa projeke.

Litšobotsi tsa karolo e tšekaletseng: Litšobotsi tsa bohlokoa tsa qubu ea tšepe e bōpehileng joaloka U li kenyelletsa sebaka, motsotso oa ho se be le nako, modulus ea karolo, le boima ka bolelele ba yuniti. Litšobotsi tsena li bohlokoa bakeng sa ho bala moralo oa sebopeho le botsitso ba qubu.

-

Theko ea Fektheri e Thehiloeng ka Sheet Sheet ea Q235 Q355 U e Chesitsoeng ka ho Chesa

Qhobosheane ea tšepe e bōpehileng joaloka Uke mofuta oa liqubu tsa tšepe tse nang le sebopeho se tšekaletseng se tšoanang le tlhaku "U". E sebelisoa hangata mererong ea boenjiniere ba sechaba le ea kaho bakeng sa lits'ebetso tse fapaneng, joalo ka mabota a ho boloka, li-cofferdams, tšehetso ea motheo le meaho ea lebopong la leoatle.

Lintlha tse qaqileng tsa qubu ea tšepe e bōpehileng joaloka U hangata li kenyelletsa litlhaloso tse latelang:

Litekanyo: Boholo le litekanyo tsa qubu ea tšepe, joalo ka bolelele, bophara le botenya, li boletsoe ho latela litlhoko tsa projeke.

Melemo e Meholo:

1.Tshebetso e ntle haholo ea ho emisa metsi

2.Ho kenya habonolo le ka katleho

3.Ho ikamahanya le maemo ho hoholo

4.E ka sebelisoa hape

5. E sireletsang tikoloho le moruo

6. Tšebeliso e phahameng ea sebaka

-

Pile ea Leqephe la Tšepe e Sebelisitsoeng e Sebetsang e Bōpehileng joaloka U e nang le Metsi Q235 Mofuta oa U Mofuta oa Leqephe la Tšepe ea Carbon

Mererong ea kaho ea sejoale-joale, botsitso ba meaho le katleho ea litšenyehelo ke tsa bohlokoa haholo. Tharollo e 'ngoe e sebetsanang le lintlha tsena ka bobeli ke ho kenya tšebetsongmabota a qubu ea tšepe.Meaho ena e feto-fetohang le e tšoarellang e fana ka khanyetso e ikhethang khahlanong le matla a mahlakoreng, e leng se etsang hore e be e loketseng bakeng sa ho itšireletsa khahlanong le khoholeho ea mobu, ho kenella ha metsi le ho se tsitse ha mobu. Ka mefuta e fapaneng, joalo ka liqubu tsa tšepe tse entsoeng ka serame le tse phutholohileng ka mocheso, le ts'ebeliso ea tšepe ea Q235, ts'ebeliso ea mabota a liqubu tsa tšepe e pharaletse haholo.

-

Tšepe e bōpehileng joaloka H ea ASTM e Chesitsoeng ka H-Beam ea Tšepe ea Carbon e Chesang e Metsi

ASTM Tšepe e Bōpehileng joaloka Hke profil e theko e tlaase ea ho sebetsa hantle ha likarolo tse fapaneng e nang le kabo e ntlafalitsoeng haholoanyane ea sebaka se fapaneng le karolelano e utloahalang ea matla-ho-boima. E rehiloe lebitso lena hobane karolo ea eona e fapaneng e tšoana le tlhaku ea Senyesemane "H". Kaha likarolo tsohle tsa H-Beam li hlophisitsoe ka likhutlo tse nepahetseng, H-Beam e na le melemo ea ho hanyetsa ho kobeha ka matla mahlakoreng 'ohle, kaho e bonolo, ho boloka litšenyehelo le boima bo bobebe ba sebopeho, 'me e sebelisitsoe haholo.

-

Sebōpeho sa ASTM sa Tšepe se Bōpehileng joaloka H sa H Beam le Sebopeho sa Karolo ea H bakeng sa Liqubu tse Chesang tse Metsuoang tsa 300×300

ASTM Tšepe e Bōpehileng joaloka H e tsejoang hape e le H-beam, ke mofuta oa lehlaka la tšepe la sebopeho le nang le karolo e tšekaletseng ka sebopeho sa tlhaku "H." Meaho ea karolo ea H e sebelisoa hangata kahong le boenjiniere ho fana ka tšehetso le bokhoni ba ho jara mojaro mehahong, marokhong le mehahong e meng. Sebopeho sa sebopeho sa karolo ea H se lumella kabo e sebetsang ea boima 'me se fana ka matla a phahameng le ho tiea, e leng se etsang hore e lokele mefuta e mengata ea lits'ebetso tsa kaho. Meaho ea karolo ea H hangata e etsoa ka tšepe 'me e hlahisoa ka lits'ebetso tse kang ho phutholla ho chesang kapa ho tjheseletsa, e leng se fellang ka thepa ea kaho e tšoarellang le e feto-fetohang.

-

Tšepe ea Karolo ea H | ASTM A36 H Beam 200 | Tšepe ea Sebopeho H Beam Q235b W10x22 100×100

Lehlaseli la ASTM A36 Hke mofuta oa lehlaseli la tšepe ea sebopeho le lumellanang le tlhaloso ea ASTM A36, e hlalosang sebopeho sa lik'hemik'hale, thepa ea mechini, le litlhoko tse ling bakeng sa tšepe ea sebopeho sa khabone. Mofuta ona oa lehlaseli la H o sebelisoa hangata boenjiniere ba kaho le ba sebopeho ka lebaka la matla a oona a phahameng, ho tjheseletsa ho babatsehang, le katleho ea litšenyehelo. Li-ASTM A36 H Beams li sebelisoa haholo mererong e fapaneng ea kaho le kaho, li fana ka tšehetso ea bohlokoa le bokhoni ba ho jara mojaro. Thepa ea thepa e etsa hore e lokele mefuta e mengata ea lits'ebetso, 'me hangata e sebelisoa kahong ea meaho, marokho le meralo e meng ea meaho. Ka ts'ebetso ea eona e tšepahalang le ho tenyetseha, ASTM A36 H Beam ke khetho e tsebahalang bakeng sa merero e mengata ea kaho.

-

Baetsi ba Chaena ba Tšepe ea Carbon e Chesitsoeng e Bōpiloeng ka U bakeng sa Kaho

Mofuta oa qubu ea pampiri ea Ue bolela mofuta oa qubu ea tšepe e bōpehileng joaloka tlhaku "U." Liqubu tsena tsa maqephe hangata li sebelisoa kahong ho etsa mabota a sireletsang, li-cofferdams le meaho e meng e hlokang ho boloka mobu kapa metsi. Sebopeho sa U se fana ka matla le botsitso, se etsa hore se lokele lits'ebetso tse fapaneng mererong ea boenjiniere ba sechaba le ea kaho.

-

ASTM A572 6mm 600X355X7mm Mofuta oa U o Thehiloeng ka Sebopeho sa Meralo e Chesang e Menoang ea Khabone e Menoang

Qhobosheane ea tšepe ea mofuta oa Uke mofuta oa thepa ea tšepe e sebelisetsoang ho boloka mabota, li-cofferdams, li-bulkheads, le lits'ebetso tse ling tse hlokang tšehetso kapa ho boloka mobu kapa metsi. E khetholloa ka karolo e tšekaletseng e bōpehileng joaloka U 'me e entsoe ka tšepe e matla haholo, e fanang ka botsitso bo botle ba sebopeho. Liqubu tsa tšepe tsa mofuta oa U li etselitsoe ho hokahana, ho theha lebota le tsoelang pele bakeng sa ts'ehetso e sebetsang ea ho boloka mobu le ho cheka. Thepa ena e feto-fetohang le e tšoarellang e sebelisoa haholo mererong ea boenjiniere ba sechaba le ea kaho e hlokang litharollo tse tšepahalang le tse sebetsang bakeng sa ho boloka le ho boloka mefuta e fapaneng ea thepa.

-

Sefate sa H sa Tšepe se Bōpehileng joaloka H sa ASTM | Sefate sa H se Mehelehileng se Chesang bakeng sa Likholomo le Likarolo tsa Tšepe

H-Beam e Chesang e Metsike leballo la sebopeho le entsoeng ka tšepe 'me le atisa ho sebelisoa mererong ea kaho le ea boenjiniere ba meaho. E na le sebopeho se ikhethang sa "H" 'me hangata e sebelisoa ho fana ka tšehetso le bokhoni ba ho jara mojaro mehahong le meahong e meng. H-Beam e Phethiloeng ka Mocheso e hlahisoa ka mokhoa oo tšepe e futhumatsoang le ho fetisoa ka har'a lirolara ho fihlela sebopeho le litekanyo tse lakatsehang. Matla a eona le ho tšoarella ha eona li etsa hore e be khetho e tsebahalang bakeng sa mefuta e mengata ea lits'ebetso tsa kaho, ho kenyeletsoa marokho, meaho le merero ea meralo ea motheo.