Lihlahisoa

-

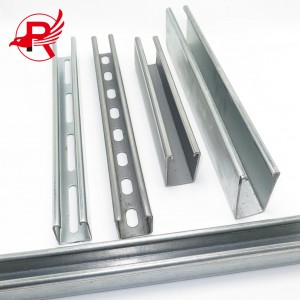

Mokero o Chesang oa Tšepe o Chesitsoeng o nang le Ce (C Purlin Unistrut, Mokero o Monyenyane oa Strut)

Sebakete sa photovoltaicE na le melemo ea ho ba bobebe, ho hanyetsa mafome, ho kenya habonolo, ho sebelisoa hape, jj., e sebelisoa haholo kahong ea sistimi ea tlhahiso ea motlakase ea photovoltaic, bracket ea photovoltaic ke skeleton e tšehetsang likarolo tsa semela sa motlakase sa photovoltaic, e ka tiisoa marulelong, fatše, metsing le maemong a mang a ts'ebeliso ea semela sa motlakase sa photovoltaic, e ka etsa hore semela sa motlakase sa photovoltaic se sebetse hantle ka lilemo tse 25.

-

Theko e Phahameng ea Boleng bo Phahameng ea China Factory Direct Steel Column Price Discount

Liqubu tsa tšepe li sebelisoa haholo masimong a mangata a kang tšehetso ea mokoti oa motheo, matlafatso ea banka, tšireletso ea lebota la leoatle, kaho ea boema-kepe le boenjiniere ba ka tlas'a lefatše. Ka lebaka la bokhoni ba eona bo botle ba ho jara, e ka sebetsana ka katleho le khatello ea mobu le khatello ea metsi. Litšenyehelo tsa tlhahiso ea qubu ea tšepe e phuthoang ka mocheso li tlase haholo, 'me li ka sebelisoa hape, 'me li na le moruo o motle. Ka nako e ts'oanang, tšepe e ka sebelisoa hape, ho latela mohopolo oa nts'etsopele e tsitsitseng. Le hoja qubu ea tšepe e phuthoang ka mocheso ka boeona e na le botsitso bo itseng, libakeng tse ling tse senyang, kalafo ea ho thibela mafome joalo ka ho koahela le ho kenya galvanizing ka mocheso hangata e sebelisoa ho eketsa bophelo ba ts'ebeletso.

-

Profaele ea ho Kenya 41*41 Strut Channel / C Channel/ Bracket ea Tšisinyeho ea Lefatše

Sebakete sa photovoltaicke sebopeho se sebelisetsoang ho kenya diphanele tsa photovoltaic. Karolo ea sona ha se feela ho lokisa module ea photovoltaic fatše kapa marulelong, empa hape ke ho lokisa Sekhutlo le tataiso ea module ea photovoltaic ho eketsa bokhoni ba ho monya matla a letsatsi. Mosebetsi o ka sehloohong oa bracket ea tšepe ea kanale ea c ke ho lokisa li-module tsa tšepe ea kanale ea c maemong a fapaneng a ts'ebeliso ea seteishene sa motlakase sa c channel joalo ka marulelo, mobu le libaka tsa metsi, ho netefatsa hore liphanele tsa letsatsi li ka lokisoa sebakeng sa tsona 'me li ka mamella matla a khoheli le khatello ea moea. E ka boela ea thusa ho lokisa sekhutlo sa liphanele tsa letsatsi ho ikamahanya le mahlaseli a fapaneng a letsatsi le ho ntlafatsa bokhoni ba tlhahiso ea matla a letsatsi.

-

Kaho ea Foreimi e le 'Ngoe ea Foreimi e le 'Ngoe e Bobebe ea 41 X 21mm

Mabakete a photovoltaice ka aroloa ka li-bracket tsa alloy ea aluminium, li-bracket tsa tšepe le li-bracket tsa polasetiki. Bracket ea alloy ea aluminium e na le litšobotsi tsa boima bo bobebe, ho hanyetsa mafome, e ntle ebile e fana ka seatla se bulehileng, empa theko e holimo; Tšehetso ea tšepe e na le melemo ea matla a phahameng, bokhoni bo matla ba ho jara le ho hanyetsa mafome, empa boima bo boholo; Bracket ea polasetiki e na le melemo ea theko e tlase, ho kenngoa habonolo le ho hanyetsa boemo ba leholimo bo matla, empa bokhoni ba ho jara bo bonyenyane.

-

EN Boleng bo Holimo ba Lehlakore la Tšepe le bōpehileng joaloka H la EN

Tšepe e bōpehileng joaloka H ke thepa ea kaho e matla haholo e nang le karolo e tšekaletseng e bōpehileng joaloka tlhaku "H". E na le melemo ea boima bo bobebe, kaho e bonolo, ho boloka thepa le ho tšoarella haholo. Moralo oa eona o ikhethang oa karolo e tšekaletseng o e etsa hore e be ntle ka bokhoni ba ho jara mojaro le botsitso ba sebopeho, 'me e sebelisoa haholo mererong ea kaho e kang mehaho e melelele, marokho, lifeme tsa indasteri le matlo a polokelo. Litlhaloso tse fapaneng le boholo ba tšepe e bōpehileng joaloka H li ka khethoa le ho fetoloa ho latela litlhoko tse itseng tsa projeke ho fihlela litlhoko tse fapaneng tsa kaho.

-

2024 Hot Rekisa Unistrut Channel P1000 Metal Strut Channel Steel Unistrut

Tšehetso ea photovoltaic ke karolo ea bohlokoa ea sistimi ea tlhahiso ea matla a photovoltaic ea letsatsi. Mosebetsi oa eona o ka sehloohong ke ho tšehetsa le ho lokisa phanele ea photovoltaic ea letsatsi ho netefatsa hore phanele ea photovoltaic e ka beoa hantle le ho shebana le letsatsi. Moralo oa bracket ea photovoltaic o hloka ho ela hloko boholo le sebopeho sa phanele ea photovoltaic ho fihlela litlhoko tsa ho kenya libakeng tse fapaneng. Hangata li khomaretsoe marulelong, fatše kapa meahong e meng, e le hore liphanele tsa photovoltaic li boloke Angle e itseng ea tšekamelo ea ho eketsa kamohelo ea mahlaseli a letsatsi le ho hlahisa motlakase.

-

Terene ea tšepe ea terene ea indasteri ea China ea boleng bo holimo ea fektheri

Terene ke motheo oa bohlokoa oa lipalangoang tsa terene, o nang le litšobotsi le melemo e mengata ea bohlokoa. Ntlha ea pele, terene e entsoe ka tšepe e matla haholo, e nang le bokhoni bo botle ba ho jara moroalo 'me e ka mamella ts'ebetso le tšusumetso ea literene tse boima. Ea bobeli, bokaholimo bo tšoeroe ka ho khetheha ho bontša khanyetso e ntle ea ho tsofala, e ka hanelang khohlano pakeng tsa lebili le terene ka katleho le ho lelefatsa bophelo ba ts'ebeletso. Ho phaella moo, terene e boloka botsitso bo botle ba jeometri tlas'a liphetoho tsa mocheso le litšusumetso tsa tikoloho, e fokotsa kotsi ea ho fetoha le tšenyo.

-

Moralo o mocha oa fektheri ea sebopeho sa tšepe / ntlo ea polokelo

Boenjiniere ba kaho,sebopeho sa tšepe tSistimi ea likarolo tsa tšepe e na le melemo e felletseng ea boima bo bobebe, tlhahiso e entsoeng fekthering, ho kenngoa ka potlako, potoloho e khuts'oane ea kaho, ts'ebetso e ntle ea litšisinyeho tsa lefatše, ho hlaphoheloa ka potlako ha matsete, le tšilafalo e fokolang ea tikoloho. Ha e bapisoa le meaho ea konkreite e matlafalitsoeng, e na le melemo e ikhethang ea likarolo tse tharo tsa nts'etsopele, lefatšeng ka bophara, haholo-holo linaheng tse tsoetseng pele le libakeng tse tsoetseng pele, likarolo tsa tšepe li 'nile tsa sebelisoa ka mokhoa o utloahalang le ka bophara lefapheng la boenjiniere ba kaho.

-

Sebopeho sa Sebaka sa Tšepe Foreimi ea Tšepe e Gabiloeng Moaho oa Bolulo

Sebopeho sa tšepeke sebopeho se entsoeng ka thepa ea tšepe 'me ke e 'ngoe ea mefuta e meholo ea meaho ea moaho. Sebopeho sena se entsoe haholo-holo ka maballo a tšepe, litšiea tsa tšepe, li-trusses tsa tšepe le likarolo tse ling tse entsoeng ka tšepe ea karolo le lipoleiti tsa tšepe, 'me se amohela silanization, phosphating e hloekileng ea manganese, ho hlatsoa le ho omisa, galvanizing le mekhoa e meng ea thibelo ea mafome. Likarolo kapa likarolo hangata li hokahantsoe ka li-welds, li-bolt kapa li-rivets. Ka lebaka la boima ba eona bo bobebe le kaho e bonolo, e sebelisoa haholo lifekthering tse kholo, libakeng tsa boikhathollo, mehahong e phahameng haholo, Marokhong le masimong a mang. Sebopeho sa tšepe se bonolo ho se rusa, sebopeho sa tšepe se akaretsang sa ho tlosa mafome, galvanized kapa pente, le tlhokomelo e tloaelehileng.

-

Meaho ea Tšepe Prefab Industrial House Construction Building Workshop Warehouse Sebopeho sa Tšepe se entsoeng esale pele

Meaho ea Tšepe S235jre na le matla a maholo le boima bo bobebe: matla a sebopeho sa tšepe a phahame haholo, 'me matla a sona a phahame ho feta a konkreite le lehong. Plastiki e ntle, thepa e ts'oanang: sebopeho sa tšepe se na le phello e ntle ea ho sisinyeha ha lefatše, thepa e ts'oanang, ts'epo e phahameng. Boemo bo phahameng ba mechini: sebopeho sa tšepe se bonolo ho se kopanya, bokhoni bo phahameng ba tlhahiso, 'me gridi ea sebopeho e nang le tekanyo e phahameng ea indasteri e na le tiiso e ntle: sebopeho sa eona se tjhitilweng se na le tiiso e ntle, kahoo moaho o hahiloeng o matla 'me phello ea ho thibela e ntle.

-

Sebopeho sa China se Theko e Tlase sa Tšepe se Lokisitsoeng esale pele Moralo oa Moaho oa Ntlo ea Polasi ea Polasi

sebopeho sa tšepee na le phello e ntle ea ho sisinyeha ha lefatše, thepa e ts'oanang, ts'epo e phahameng. Boemo bo phahameng ba mechini: sebopeho sa tšepe se bonolo ho se kopanya, bokhoni bo phahameng ba tlhahiso, 'me gridi ea sebopeho e nang le tekanyo e phahameng ea indasteri e na le tiiso e ntle: sebopeho sa eona se kopantsoeng se na le tiiso e ntle, kahoo moaho o hahiloeng o matla 'me phello ea ho thibela e ntle.

-

Mofani oa Chaena oa Terene ea GB ea Tšepe e Tloaelehileng Terene e Boima ea Terene le Tsela ea Terene e Bobebe ea Terene Bakeng sa Merafo

Terene ea tšepeke karolo e ka sehloohong ea seporo sa terene. Mosebetsi oa sona ke ho tataisa mabili a seporo se ntseng se bilikana ho ea pele, ho mamella khatello e kholo ea mabili, le ho fetisetsa ho motho ea robalang. Seporo se tlameha ho fana ka sebaka se bilikanang se tsoelang pele, se boreleli, le se sa haneleng lebili. Karolong ea terene e nang le motlakase kapa ea block e iketsang, seporo se ka boela sa sebelisoa e le potoloho ea seporo.