Lihlahisoa

-

EN Boholo bo Tloaelehileng H Beam Steel HEA HEB IPE 150×150 H beam Theko

HEA,HEB, le HEM ke mabitso a likarolo tsa IPE (I-beam) tse tloaelehileng tsa Europe.

-

Tšepe e entsoeng ka mokhoa o ikhethileng Tšepe e entsoeng ka tšepe e chesang e kentsoeng ka tšepe e 150 5mm C Purlin Channel

Tšepe ea kanale ea Cke sehlahisoa sa tšepe sa meaho se nang le likarolo tse ngata tse nang le karolo e bōpehileng joaloka "C" kapa "U", e nang le lebanta le sephara le li-flange tse peli. E tsebahala ka karolelano ea eona e phahameng ea matla-ho-boima, e atisa ho sebelisoa kahong, tlhahisong le boenjiniere bakeng sa tšehetso, ho tiisa le ho foreimi.

-

Tšepe ea Mokero e Thibelang ho Senyeha ea Boleng bo Holimo e Chesitsoeng e Chesitsoeng ea 2 3 4 inch C

Mabakete a photovoltaichaholo-holo e sebetsa likarolong tse latelang:

Ntlafatsa bokgoni ba phetoho ya diphanele tsa photovoltaic: Dibracket tsa photovoltaic di ka kenya diphanele tsa photovoltaic ka dikhutlo le ditaelo tse loketseng ho eketsa ho monyeha ha matla a letsatsi le ho fetoha matla a motlakase.

Ntlafatsa botsitso ba diphanele tsa photovoltaic: Dibracket tsa photovoltaic di ka tiisa diphanele tsa photovoltaic fatshe kapa marulelong ka thata, mme di ka hanela ka katleho tshusumetso ya moya, pula, lehlwa le maemo a mang a tlhaho diphaneleng tsa photovoltaic ho tswa mahlakoreng a fapaneng.

Fokotsa litšenyehelo tsa litsamaiso tsa photovoltaic: Li-bracket tsa photovoltaic li ka fokotsa litšenyehelo tsa ho kenya, litšenyehelo tsa tlhokomelo le litšenyehelo tsa ts'ebetso ea litsamaiso tsa photovoltaic, ka hona li ntlafatsa melemo ea moruo le puseletso ea matsete a litsamaiso tsa photovoltaic. -

Matla a Phahameng a Meaho a Ikhethileng a 6 intshi 8 intshi a Chesang a Phutholohileng Tšepe H Beam

Tšepe e bōpehileng joaloka Hke profil e theko e tlase, e sebetsang hantle haholo e nang le kabo e ntlafalitsoeng ea sebaka se tšekaletseng le karolelano e utloahalang ea matla ho ea boima. E fumana lebitso la eona ho tsoa karolong ea eona e tšekaletseng e tšoanang le tlhaku "H." Hobane likarolo tsa eona li hlophisitsoe ka likhutlo tse nepahetseng, tšepe e bōpehileng joaloka H e fana ka melemo e kang ho hanyetsa ho kobeha ka matla mahlakoreng 'ohle, kaho e bonolo, ho boloka litšenyehelo le meaho e bobebe, e leng se etsang hore e sebelisoe haholo.

-

JIS/ASTM e Phethahetseng e Chesang ea 6m 10m Tšepe ea H bakeng sa Kaho

Lehlaseli la HTšepe, mofuta oa tšepe e nang le karolo e tšekaletseng e bōpehileng joaloka H, e sebelisoa haholo kahong ea meaho ka lebaka la matla a eona a matle, botsitso le ho hanyetsa ho fetoha ha sebopeho. E tsejoang hape e le tšepe ea I-beam kapa I-beam, tšepe ea H-beam e sebelisoa haholo mehahong, marokhong, mechineng le masimong a mang, 'me e loketse haholo mehaho e jarang mojaro le ea foreimi.

-

Theko ea Thekiso ea Fektheri ea Chaena e Ikhethileng Boleng bo Ikhethang ba Leqephe la Tšepe la U le Tšepahalang

Qubu ea tšepe e sebelisoa haholo boenjiniere ba sechaba. Qubu ea tšepe e na le matla a maholo 'me e ka mamella khatello e kholo ea lefatše le khatello ea metsi, e leng se loketseng tšireletso ea mokoti o tebileng oa motheo le lebopong la noka. Ea bobeli, katleho ea kaho e phahame, lebelo la ho kenya le potlakile, e leng se ka khutsufatsang nako ea kaho le ho fokotsa litšenyehelo. Ho phaella moo, qhoubu ea tšepe e na le ts'ebetso e ntle ea ho se kenelle metsi, e ka thibelang ho kenella ha metsi ka katleho le ho sireletsa tikoloho e potolohileng. Qetellong, qhoubu ea tšepe e ka sebelisoa hape, e tenyetseha haholo, e hanyetsa mafome hantle, e loketse ho sebelisoa libakeng tse thata.

-

Lifeme tsa Chaena li rekisa Cold Formed U Shaped Steel Sheet Pile

Qubu ea tšepe ke thepa ea sebopeho sa tšepe e sebelisoang boenjiniere ba sechaba le kaho. Hangata e ka sebopeho sa lipoleiti tse telele tsa tšepe tse nang le botenya le matla a itseng. Mosebetsi o ka sehloohong oa liqubu tsa tšepe ke ho tšehetsa le ho arola mobu le ho thibela tahlehelo le ho putlama ha mobu. Li sebelisoa haholo tšehetsong ea mokoti oa motheo, taolong ea noka, kahong ea kou le masimong a mang.

-

Liqhomane tsa tšepe tsa U tsa boleng bo holimo tsa China Factory

Melemo ea qubu ea tšepe indastering e bonahala haholo-holo ka matla a eona a phahameng le ho tšoarella ha eona, e ka hanelang khatello ea mobu le khatello ea metsi ka katleho, 'me e loketse meaho ea tšehetso ea nakoana le ea kamehla. E bobebe ebile e bonolo ho e tsamaisa le ho e kenya, lebelo la kaho le potlakile, 'me litšenyehelo tsa basebetsi lia fokotseha. Ho phaella moo, ho sebelisoa hape le litšobotsi tsa tikoloho tsa qubu ea tšepe li etsa hore li ratoe mererong ea nts'etsopele e tsitsitseng, e loketseng lits'ebetso tse fapaneng joalo ka likou, mabopong a linoka, meralo ea motheo le tse ling.

-

Meaho ea Tšepe e Lokisitsoeng esale pele e theko e tlase ebile e boleng bo holimo

Sebopeho sa tšepe ke sebopeho se entsoeng ka thepa ea tšepe 'me ke e 'ngoe ea mefuta e meholo ea sebopeho sa moaho. Sebopeho sena se entsoe haholo-holo ka maballo a tšepe, litšiea tsa tšepe, li-trusses tsa tšepe le likarolo tse ling tse entsoeng ka tšepe ea karolo le lipoleiti tsa tšepe, 'me se amohela silanization, manganese phosphating e hloekileng, ho hlatsoa le ho omisa, galvanizing le mekhoa e meng ea thibelo ea mafome.

*Ho latela kopo ea hau, re ka rala sistimi ea foreimi ea tšepe e theko e tlaase le e tšoarellang ka ho fetisisa ho u thusa ho theha boleng bo holimo bakeng sa projeke ea hau.

-

Tšepe e Sireletsang Q235 Q345 A36 A572 Kereiti ea HEA HEB HEM 150 Khabone Tšepe ea H/I Beam

Libalaka tsa H, ka karolo ea tsona e bōpehileng joaloka H, hangata li sebelisoa e le likarolo tsa mantlha tse jarang mojaro mererong e kang marokho le lifeme ka lebaka la thepa ea tsona e ntle ea mechini.

-

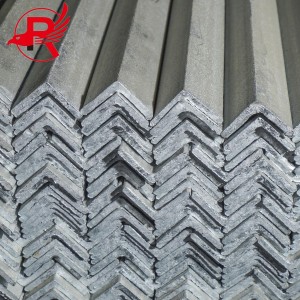

ASTM A36 / A53 / Q235 / Q345 Khabone Tšepe e Lekanang ea Angle Bar – Tšepe e Bonolo e Gabiloeng (e Bōpehileng joaloka V)

Tšepe ea Angle e Lekanang ea ASTM e tsejoang haholo e le tšepe ea sekhutlo, ke tšepe e telele e nang le mahlakore a mabeli a otlolohileng.

Tšepe ea Angle e Lekanang le e sa Lekaneng:

-

Tšepe e Lekanang ea Angle:Maoto ka bobeli a lekana ka bophara. Litlhaloso li hlalositsoe ka tsela enabophara ba lehlakore × bophara ba lehlakore × botenyaka mm, mohlala,∟30 × 30 × 3(Bophara ba 30 mm, botenya ba 3 mm).

-

Referense ea Mohlala:Ka linako tse ling e hlahisoa ka cm, mohlala,∟3 × 3, empa sena ha se bontše botenya. Kamehla hlalosabophara le botenya ba leotolikonteraka le litokomaneng.

-

Boholo bo Tloaelehileng ba Meqolo e Chesang:Tšepe e lekanang le e nang le sekhutlo sa leoto e tloha ho2 × 3 mm ho isa ho 20 × 3 mm.

-

-

Bare ea Tšepe e Chesang e 6# e Lekanang ea Chaena, e nang le Galvanized ea 90 Degree

Tšepe ea Angle e Tšoanang e Gakalitsoeng, e tsejoang haholo e le tšepe ea sekhutlo, ke tšepe e telele e nang le mahlakore a mabeli a otlolohileng. Ho na le tšepe ea sekhutlo e lekanang le tšepe ea sekhutlo e sa lekanang. Bophara ba mahlakore a mabeli a tšepe ea sekhutlo e lekanang bo lekana. Tlhaloso e hlalosoa ka mm ea bophara ba lehlakore × bophara ba lehlakore × botenya ba lehlakore. Joalo ka "∟ 30 × 30 × 3″, ke hore, tšepe ea sekhutlo e lekanang le bophara ba lehlakore ba 30mm le botenya ba lehlakore ba 3mm. E ka boela ea hlalosoa ka mohlala. Mohlala ke lisenthimithara tsa bophara ba lehlakore, joalo ka ∟ 3 × 3. Mohlala ha o emele litekanyo tsa botenya bo fapaneng ba lehlakore mohlaleng o tšoanang, kahoo bophara ba lehlakore le botenya ba lehlakore ba tšepe ea sekhutlo bo tla tlatsoa ka botlalo konterakeng le litokomaneng tse ling ho qoba ho sebelisa mohlala feela. Tlhaloso ea tšepe ea sekhutlo e lekanang le leoto e phutholohileng ke 2 × 3-20 × 3.