Seporo sa Tšepe sa ISCOR Moetsi oa Seporo sa Tšepe e Boima

Ho latela mokhoa oa tlhahiso,Literene tse nang le Galvanizede ka aroloa haholo-holo ka literene tse phuthoang ka mocheso le literene tse phekoloang ka mocheso. Ha e le hantle, literene li hlahisoa ka mokhoa oa ho phuthoang ka mocheso. Literene tse phekoang ka mocheso li phekolloa ka mocheso hape ka mor'a hore literene tse phuthoang ka mocheso li thehoe. Li arotsoe ka mefuta e 'meli: kalafo ea mocheso inthaneteng le kalafo ea mocheso kantle ho inthanete. Kalafo ea mocheso inthaneteng e se e ntse e le eona e ka sehloohong, e leng ho boloka matla haholoanyane le ho sebetsa hantle haholoanyane.

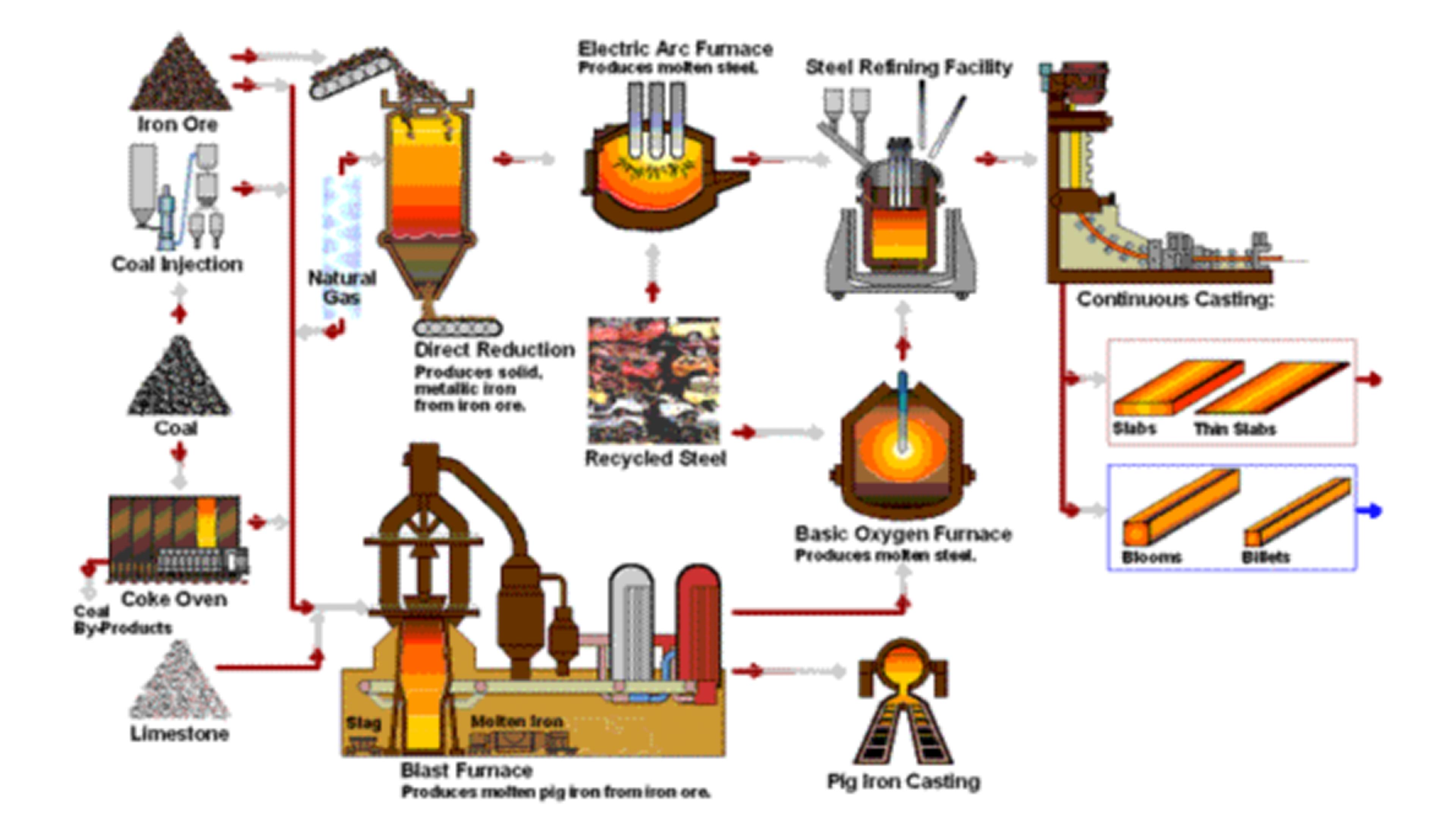

Mokhoa oa Tlhahiso ea Sehlahisoa

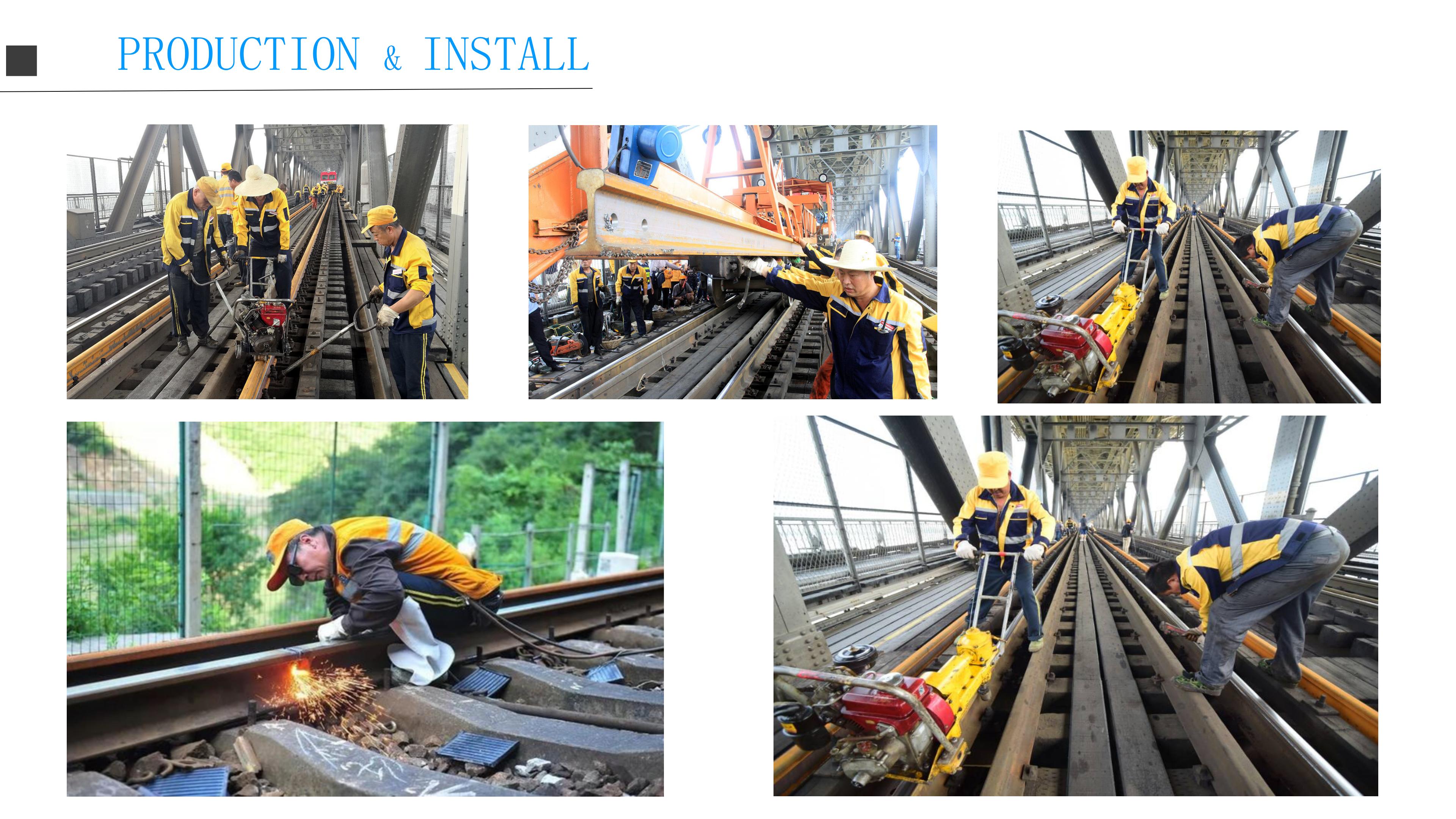

Theknoloji le Ts'ebetso ea Kaho

Mokhoa oa ho hahaseporo sa tšepe sa chinaLiterata li kenyelletsa boenjiniere bo nepahetseng le ho nahana ka hloko ka lintlha tse fapaneng. E qala ka ho rala moralo oa literata, ho nahanoa ka tšebeliso e reriloeng, lebelo la terene le sebaka. Hang ha moralo o phethetsoe, ts'ebetso ea kaho e qala ka mehato ea bohlokoa e latelang:

1. Ho Epa le Motheo: Sehlopha sa kaho se lokisa mobu ka ho epa sebaka seo le ho theha motheo o tiileng ho tshehetsa boima le kgatello e bakwang ke diterene.

2. Ho Kenya Ballast: Lera la lejoe le pshatlehileng, le tsejoang e le ballast, le beoa holim'a bokaholimo bo lokisitsoeng. Sena se sebetsa e le lera le monyang ho thothomela, le fanang ka botsitso, le ho thusa ho aba mojaro ka ho lekana.

3. Lithapo le ho Tiisa: Lithapo tsa lehong kapa tsa konkreite li kenngoa holim'a ballast, li etsisa sebopeho se kang foreimi. Lithapo tsena li fana ka motheo o sireletsehileng bakeng sa litsela tsa terene tsa tšepe. Li tlamelloa ka ho sebelisa li-spikes kapa li-clip tse itseng, ho netefatsa hore li lula li tiile sebakeng sa tsona.

4. Ho Kenya Terene: Literene tsa tšepe tsa 10m, tse atisang ho bitsoa literene tse tloaelehileng, li behiloe ka hloko holim'a lithapo. Kaha li entsoe ka tšepe ea boleng bo holimo, litsela tsena li na le matla a makatsang le ho tšoarella.

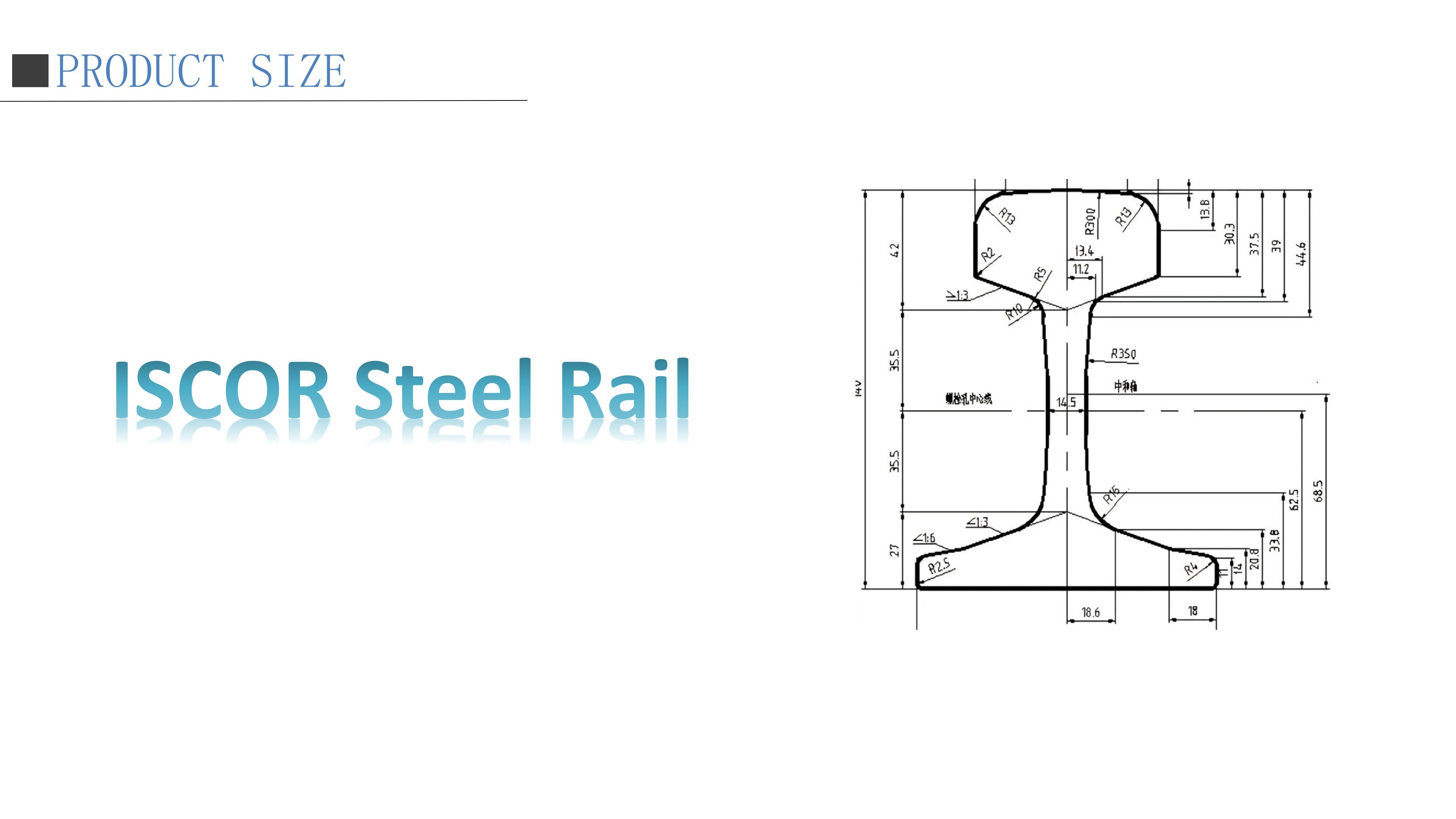

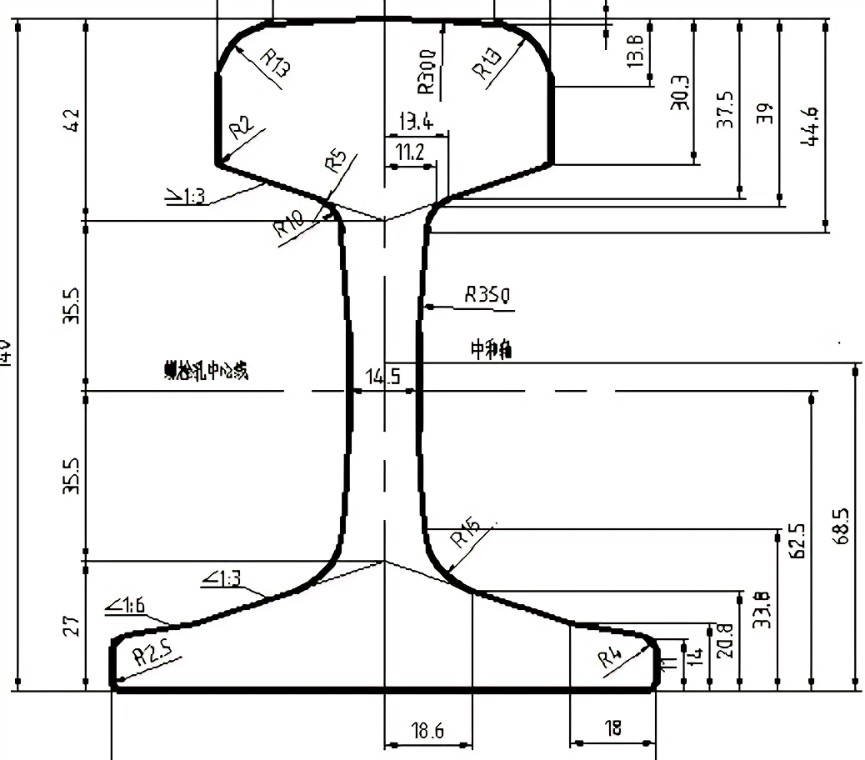

BOHOLO BA SEHLAHISOA

| Terene ea tšepe e tloaelehileng ea ISCOR | |||||||

| mohlala | boholo (mm) | ntho | boleng ba thepa | bolelele | |||

| bophara ba hlooho | bophahamo | boto ea motheo | botebo ba letheka | (kg/m) | (m) | ||

| A(mm) | B(mm) | C(mm) | D(mm) | ||||

| 15KG | 41.28 | 76.2 | 76.2 | 7.54 | 14.905 | 700 | 9 |

| 22KG | 50.01 | 95.25 | 95.25 | 9.92 | 22.542 | 700 | 9 |

| 30KG | 57.15 | 109.54 | 109.54 | 11.5 | 30.25 | 900A | 9 |

| 40KG | 63.5 | 127 | 127 | 14 | 40.31 | 900A | 9-25 |

| 48KG | 68 | 150 | 127 | 14 | 47.6 | 900A | 9-25 |

| 57KG | 71.2 | 165 | 140 | 16 | 57.4 | 900A | 9-25 |

Terene ea tšepe ea ISCOR:

Litlhaloso: 15kg, 22kg, 30kg, 40kg, 48kg, 57kg

Tekanyetso: ISCOR

Bolelele: 9-25m

MOLEMO

1. Litšobotsi tsa literene

1. Matla a Phahameng: Kamora moralo o ntlafalitsoeng le mokhoa o khethehileng oa thepa, literene li na le matla a holimo a kobehang le matla a ho hatella, 'me li ka mamella mojaro o boima le tšusumetso ea terene, ho netefatsa polokeho le botsitso ba lipalangoang tsa terene.

2. Ho hanyetsa ho roala: Bokaholimo ba terene bo na le bothata bo phahameng le coefficient e nyane ea khohlano, e ka hanelang ho roala ha mabili le literene tsa terene le ho lelefatsa bophelo ba tšebeletso.

3. Botsitso bo botle: Literene li na le litekanyo tse nepahetseng tsa jeometri le litekanyo tse tsitsitseng tse otlolohileng le tse otlolohileng, tse ka netefatsang ts'ebetso e boreleli ea terene le ho fokotsa lerata le ho thothomela.

4. Kaho e bonolo: Literei li ka hokahanngoa bolelele bofe kapa bofe ka manonyeletso, e leng se etsang hore ho be bonolo ho kenya le ho nkela literei sebaka.

5. Litšenyehelo tse tlase tsa tlhokomelo: Literene li tsitsitse ebile lia tšepahala nakong ea lipalangoang, 'me li na le litšenyehelo tse tlase tsa tlhokomelo.

2. Tšebeliso ea literene

1. Lipalangoang tsa terene: Literene tsa tšepe li sebelisoa haholo lipalangoangng tsa terene, ho kenyeletsoa lipalangoang tsa bapalami le tsa thepa tsa terene, literene tse tsamaeang ka tlas'a lefatše, literene tse lebelo le phahameng, jj., 'me ke likarolo tsa motheo tsa lipalangoang tsa terene.

2. Litšebeletso tsa koung: Litšebeletso tsa tšepe li sebelisoa masimong a thepa a kang libaka tsa ho lata thepa le mabala e le litšebeletso tsa ho phahamisa thepa, lisebelisoa tsa ho lata thepa ka har'a lijana, jj. ho nolofatsa ho kenya, ho lata le ho tsamaisa lijana le thepa.

3. Sepalangoang sa merafo: Literene tsa tšepe li ka sebelisoa merafong le masimong a merafo e le lisebelisoa tsa lipalangoang ka har'a merafo ho nolofatsa merafo le lipalangoang tsa liminerale.

Ka bokhutšoanyane, e le karolo ea motheo ea lipalangoang tsa literene, literene li na le melemo ea matla a phahameng, ho hanyetsa ho tsofala, botsitso bo matla, kaho e bonolo le litšenyehelo tse tlase tsa tlhokomelo. Li sebelisoa haholo litereneng, thepa ea koung, lipalangoang tsa merafo le masimong a mang.

MORERO

Khamphani ea rona'Literene tsa tšepe tse boima ba lithane tse 13,800 tse rometsoeng United States li ile tsa romeloa Koung ea Tianjin ka nako e le 'ngoe. Morero oa kaho o phethiloe ka terene ea ho qetela e ntseng e beoa butle-butle moleng oa terene. Literene tsena kaofela li tsoa moleng oa tlhahiso oa lefats'e oa fektheri ea rona ea literene le mahlakore a tšepe, ho sebelisoa lefats'e ka bophara. E hlahisitsoe ka maemo a holimo le a thata ka ho fetisisa a tekheniki.

Bakeng sa tlhahisoleseling e batsi ka lihlahisoa tsa terene, ka kopo ikopanye le rona!

WeChat: +86 13652091506

Mohala: +86 13652091506

Imeile:[email protected]

KOPO

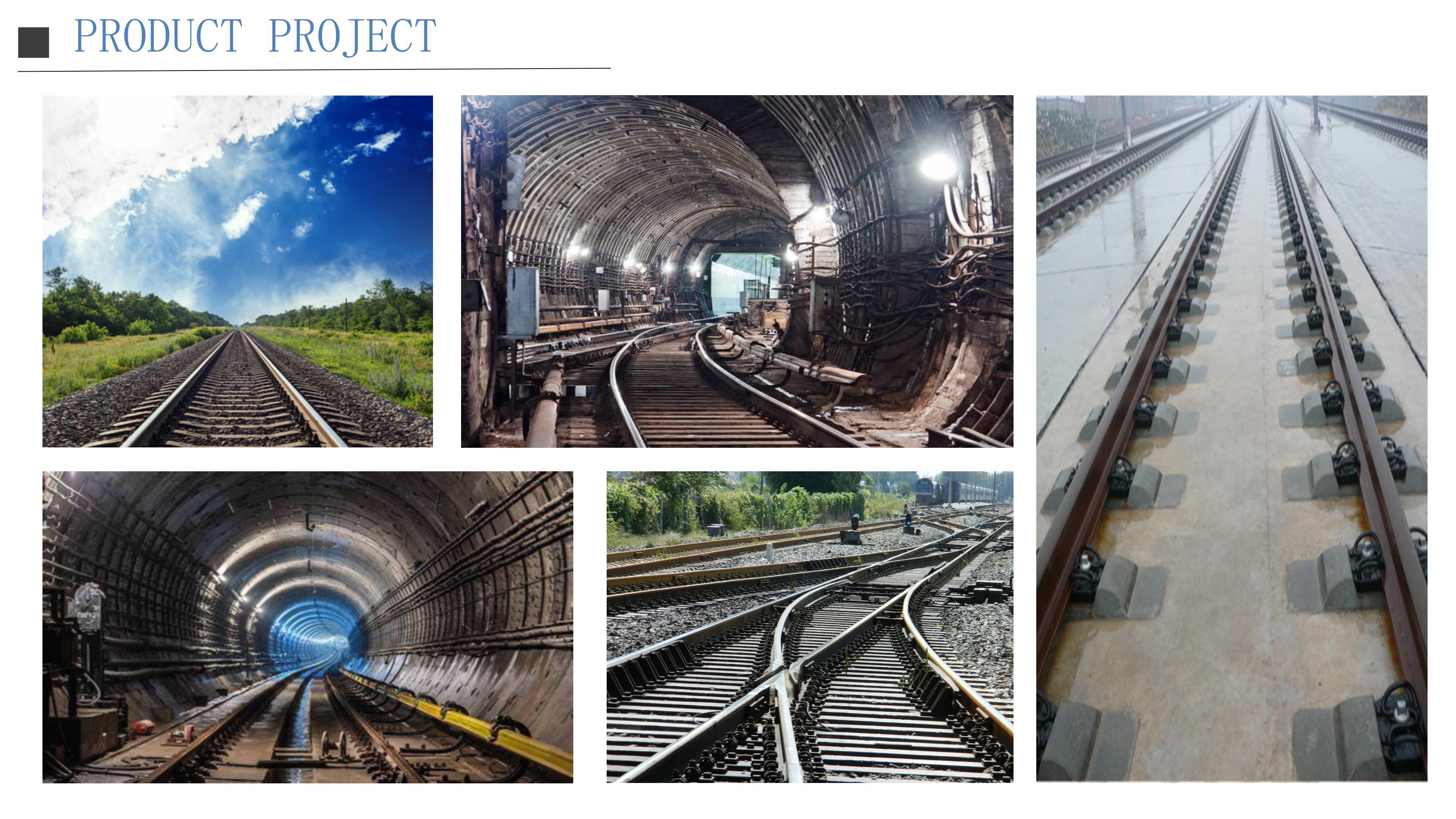

Literene li sebelisoa haholo libakeng tse latelang:

Sistimi ea lipalangoang tsa literene: Literene ke meralo ea motheo e hlokahalang bakeng sa literene ho tsamaea litereneng 'me li sebelisetsoa ho fana ka litsela tse tsitsitseng. Ebang ke terene e tloaelehileng, terene e lebelo le phahameng kapa terene e tsamaeang ka tlas'a lefatše, literene lia hlokahala ho tšehetsa le ho tataisa terene.

Sistimi ea terene e tsamaeang ka tlas'a lefatše: Sistimi ea terene e tsamaeang ka tlas'a lefatše ke lipalangoang tse tloaelehileng tsa sechaba metseng e meholo. Literene le tsona ke karolo ea bohlokoa ea litsela tsa terene e tsamaeang ka tlas'a lefatše, ho netefatsa hore literene li tsamaea hantle lithaneleng tse ka tlas'a lefatše.

Terene e nang le motlakase: Terene e nang le motlakase ke sistimi ea terene e sebelisang motlakase ho khanna literene. Literene tsa tšepe li boetse li sebelisoa ho haha literene tseo literene li ka tsamaeang ho tsona.

Terene e lebelo le phahameng: Terene e lebelo le phahameng ke sistimi ea terene e nang le literene tse lebelo le phahameng e le mojari o sebetsang. Literene li tlameha ho khona ho mamella tšusumetso le mojaro o boima oa literene tse lebelo le phahameng ho netefatsa polokeho le botsitso ba literene tse lebelo le phahameng.

Tšebeliso ea indasteri: Ntle le lefapha la lipalangoang, literene tsa tšepe li ka boela tsa sebelisoa libakeng tse ling tsa indasteri, joalo ka literene kapa litsamaiso tsa thepa likoung, merafong, jj., ho fana ka motheo oa ho khanna literene kapa likoloi.

Ka bokhutšoanyane, literene li phetha karolo ea bohlokoa ts'ebetsong ea litsamaiso tse fapaneng tsa lipalangoang le tsa indasteri ha ka nako e ts'oanang li fana ka litsela tse tsitsitseng tsa maeto, li tšehetsa meroalo e boima, 'me li netefatsa polokeho.

HO PHAKISA LE HO ROMELA

Literene li sebelisoa haholo libakeng tse latelang:

Sistimi ea lipalangoang tsa literene: Literene ke meralo ea motheo e hlokahalang bakeng sa literene ho tsamaea litereneng 'me li sebelisetsoa ho fana ka litsela tse tsitsitseng. Ebang ke terene e tloaelehileng, terene e lebelo le phahameng kapa terene e tsamaeang ka tlas'a lefatše, literene lia hlokahala ho tšehetsa le ho tataisa terene.

Sistimi ea terene e tsamaeang ka tlas'a lefatše: Sistimi ea terene e tsamaeang ka tlas'a lefatše ke lipalangoang tse tloaelehileng tsa sechaba metseng e meholo. Literene le tsona ke karolo ea bohlokoa ea litsela tsa terene e tsamaeang ka tlas'a lefatše, ho netefatsa hore literene li tsamaea hantle lithaneleng tse ka tlas'a lefatše.

Terene e nang le motlakase: Terene e nang le motlakase ke sistimi ea terene e sebelisang motlakase ho khanna literene. Literene tsa tšepe li boetse li sebelisoa ho haha literene tseo literene li ka tsamaeang ho tsona.

Terene e lebelo le phahameng: Terene e lebelo le phahameng ke sistimi ea terene e nang le literene tse lebelo le phahameng e le mojari o sebetsang. Literene li tlameha ho khona ho mamella tšusumetso le mojaro o boima oa literene tse lebelo le phahameng ho netefatsa polokeho le botsitso ba literene tse lebelo le phahameng.

Tšebeliso ea indasteri: Ntle le lefapha la lipalangoang, literene tsa tšepe li ka boela tsa sebelisoa libakeng tse ling tsa indasteri, joalo ka literene kapa litsamaiso tsa thepa likoung, merafong, jj., ho fana ka motheo oa ho khanna literene kapa likoloi.

Ka bokhutšoanyane, literene li phetha karolo ea bohlokoa ts'ebetsong ea litsamaiso tse fapaneng tsa lipalangoang le tsa indasteri ha ka nako e ts'oanang li fana ka litsela tse tsitsitseng tsa maeto, li tšehetsa meroalo e boima, 'me li netefatsa polokeho.

MATLA A K'hamphani

E entsoe Chaena, tšebeletso ea boemo ba pele, boleng bo holimo, e tsebahala lefatšeng ka bophara

1. Phello ea sekala: Khamphani ea rona e na le ketane e kholo ea phepelo le fektheri e kholo ea tšepe, e fihlelang liphello tse kholo lipalangoang le theko, 'me e fetoha k'hamphani ea tšepe e kopanyang tlhahiso le lits'ebeletso.

2. Mefutafuta ya dihlahiswa: Mefutafuta ya dihlahiswa, tshepe efe kapa efe eo o e batlang e ka rekwa ho rona, haholo-holo e sebetsanang le meaho ya tshepe, di-rails tsa tshepe, di-sheet pile tsa tshepe, di-bracket tsa photovoltaic, tshepe ya kanale, di-coil tsa tshepe tsa silicon le dihlahiswa tse ding, e leng se etsang hore e tenyetsehe haholoanyane. Khetha mofuta wa sehlahiswa o lakatsehang ho fihlela ditlhoko tse fapaneng.

3. Phepelo e tsitsitseng: Ho ba le mohala o tsitsitseng oa tlhahiso le ketane ea phepelo ho ka fana ka phepelo e tšepahalang haholoanyane. Sena se bohlokoa haholo ho bareki ba hlokang tšepe e ngata.

4. Tšusumetso ea lets'oao: E na le tšusumetso e phahameng ea lets'oao le 'maraka o moholo

5. Tšebeletso: Khamphani e kholo ea tšepe e kopanyang mokhoa oa ho iketsetsa, lipalangoang le tlhahiso

6. Tlholisano ea theko: theko e utloahalang

*Romella imeile ho[email protected]ho fumana khotheishene bakeng sa merero ea hau

KETO EA BAREKI

LBH

1. Nka fumana khotheishene joang ho tsoa ho uena?

O ka re siela molaetsa, 'me re tla araba molaetsa o mong le o mong ka nako.

2. Na o tla isa thepa ka nako?

E, re tšepisa ho fana ka lihlahisoa tsa boleng bo holimo le ho li tlisa ka nako. Botšepehi ke molao-motheo oa k'hamphani ea rona.

3.Na nka fumana disampole pele ke odara?

E, ehlile. Hangata disampole tsa rona ha di lefellwe, re ka di hlahisa ka disampole tsa hao kapa ka ditshwantsho tsa botekgeniki.

4. Lipehelo tsa hau tsa tefo ke life?

Nako ea rona ea tefo e tloaelehileng ke depositi ea 30%, 'me karolo e setseng khahlanong le B/L. EXW, FOB, CFR, CIF.

5. Na o amohela tlhahlobo ea motho oa boraro?

E, ruri rea amohela.

6. Re tšepa khamphani ea hau joang?

Re ikhethile khoebong ea tšepe ka lilemo tse ngata re le mofani oa khauta, ntlo-kholo e profinseng ea Tianjin, re amohelehile ho etsa lipatlisiso ka litsela life kapa life, ka mekhoa eohle.