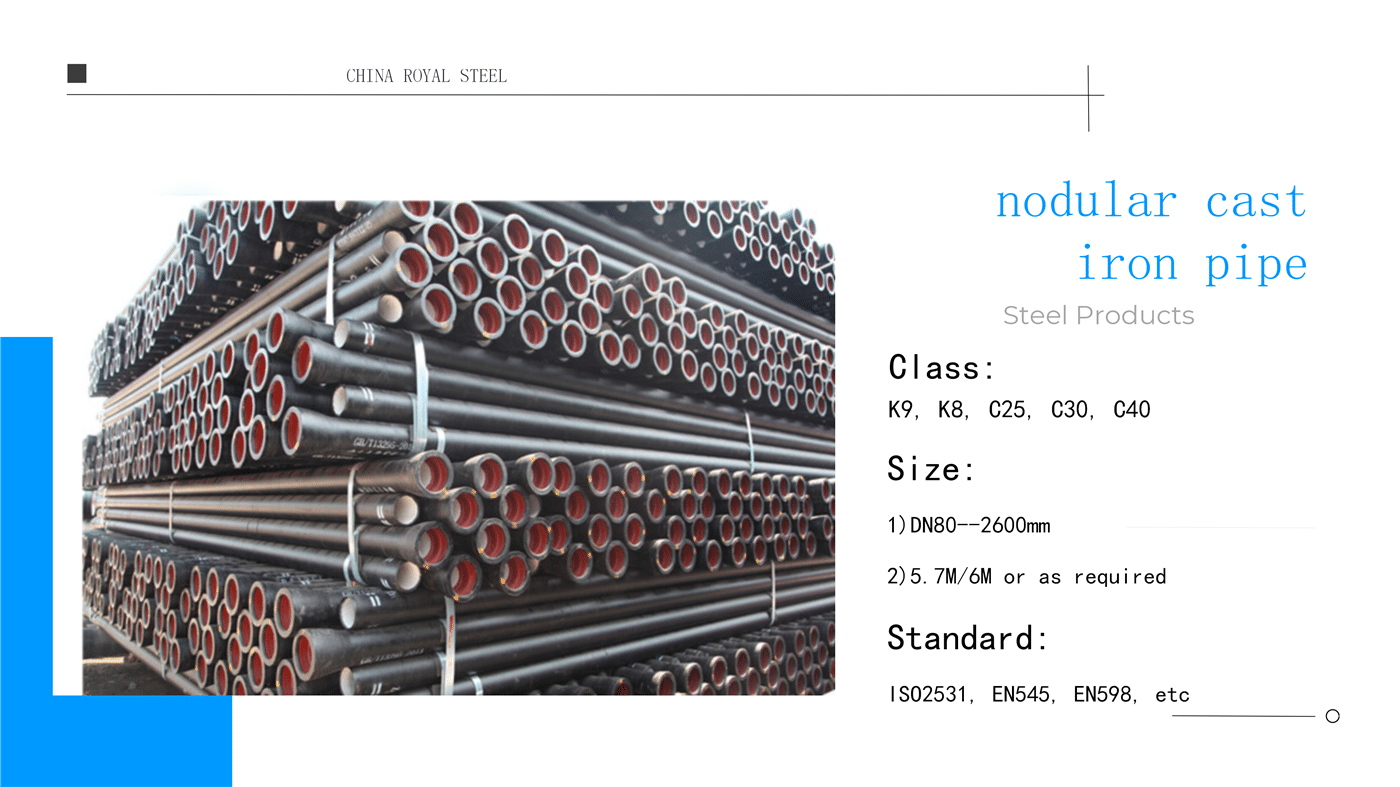

Nodular cast iron pipe

Lintlha tsa Sehlahisoa

Liphaephe tsa tšepe tsa nodular cast iron ha e le hantle ke liphaephe tsa tšepe tsa ductile, tse nang le moelelo oa tšepe le thepa ea tšepe, ke ka hona li rehoang lebitso. Graphite ka liphaephe tsa tšepe tsa ductile e teng ka sebopeho sa spherical, ka boholo bo akaretsang ba limaraka tse 6-7. Mabapi le boleng, boemo ba spheroidization ba liphaephe tsa tšepe tse entsoeng ka tšepe bo hlokeha ho laoloa maemong a 1-3, ka tekanyo ea spheroidization ea ≥ 80%. Ka hona, thepa ea mechine ea thepa ka boeona e ntlafalitsoe, e nang le mohloli oa tšepe le thepa ea tšepe. Ka mor'a ho kenngoa, microstructure ea liphaephe tsa tšepe ea ductile ke ferrite e nang le pearlite e nyenyane, e nang le thepa e ntle ea mochine, kahoo e boetse e bitsoa liphaephe tsa tšepe tse entsoeng ka tšepe.

| Lihlahisoa tsohle tse hlalositsoeng li ka etsoa ho latela litlhoko tsa bareki | |

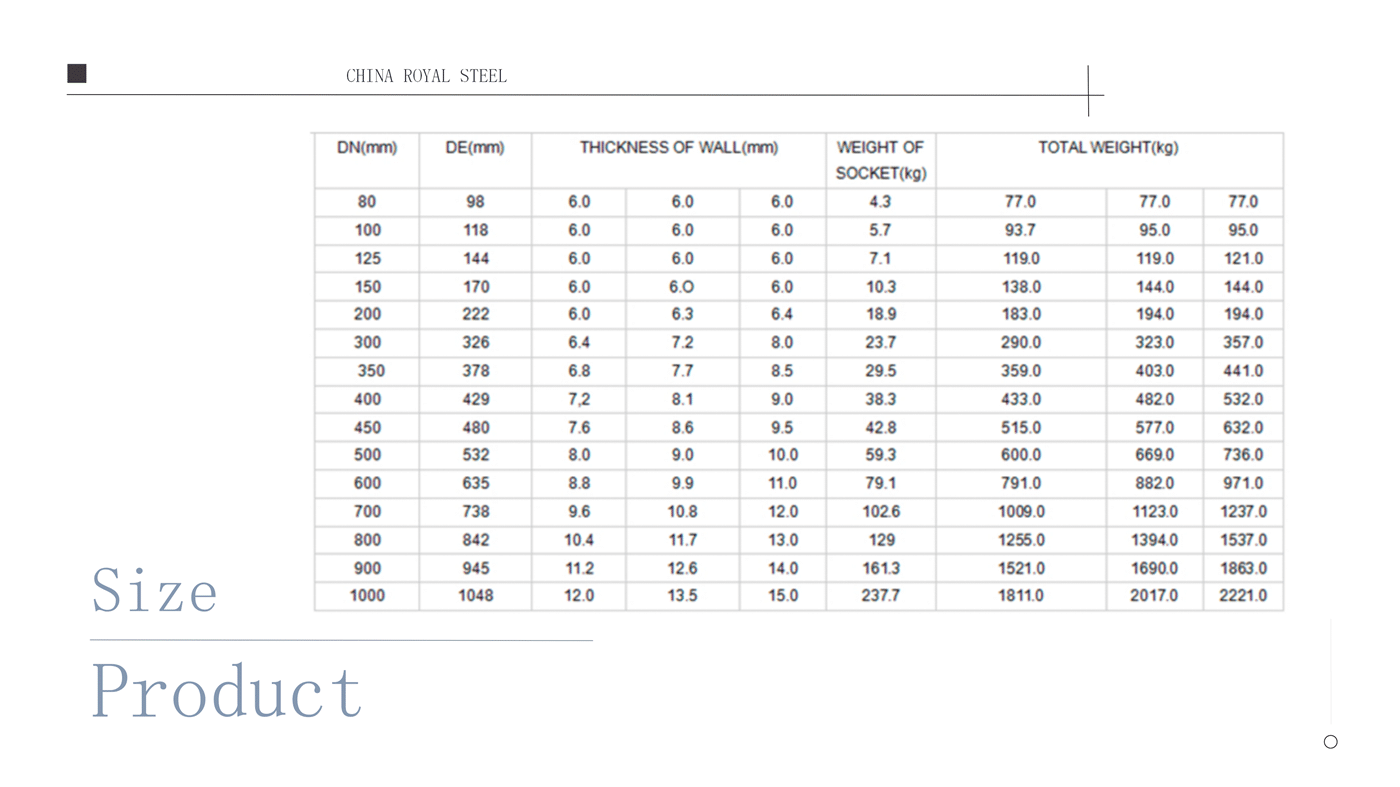

| 1. Boholo | 1)DN80 ~ 2600mm |

| 2) 5.7M/6M kapa ha ho hlokahala | |

| 2. Maemo: | ISO2531, EN545, EN598, joalo-joalo |

| 3.Material | Ductile Cast Iron GGG50 |

| 4. Sebaka sa feme ea rona | Tianjin, China |

| 5. Tšebeliso: | 1)Metsi a litoropo |

| 2) liphaephe tsa ho kheloha | |

| 3) tsa temo | |

| 6. Koala ka hare: | a). Seretse sa samente sa Portland b). Seretse sa samente se hanyetsanang le sulphate c). Lerako la seretse sa samente sa Aluminium e phahameng d). Sekoaelo sa epoxy se kopantsoeng le Fusion e). Pente ea epoxy ea mokelikeli f). Pente e ntšo ea sekontiri |

| 7. Ho roala ka ntle: | . zinki+sekontiri(70microns) ho penta . Sekoaelo sa epoxy se kopantsoeng le Fusion c). Zinc-aluminium alloy+liquid epoxy penta |

| 8. Mofuta: | Welded |

| 9. Tshebeletso ya Tshebetso | Ho tjheseletsa, ho Kobeha, Ho phunya, ho qhibidiha, ho seha |

| 10. MOQ | 1 Ton |

| 11. Thomello: | Lingata, ka bongata, |

1. Ts'ebetso ea ho hanyetsa khatello ea ka hare:

Centrifugal ductile iron e na le moelelo oa tšepe le ts'ebetso ea tšepe, kahoo liphaephe tsa tšepe tsa ductile li na le ts'ebetso e ntle ea ts'ireletso ho feta liphaephe tse entsoeng ka lisebelisoa tse ling. Khatello ea ts'ebetso e entsoeng e phahame haholo ho feta ea liphaephe tse entsoeng ka lisebelisoa tse ling, ntho e sireletsehileng e phahame haholo, 'me khatello ea ho phatloha e ka bang teng.

makhetlo a mararo a khatello ea ho sebetsa.

2. Ts'ebetso ea khanyetso ea khatello ea kantle:

Ho hanyetsa khatello e phahameng ho ka qoba tlhokahalo ea bethe ea liphaephe le sekoahelo se sireletsang, ho etsa hore liphaephe tse behiloeng li rellable le tsa moruo.

3.Inner anti-corrosion layer:

Lera le ka hare la liphaephe tsa tšepe tsa ductile li fafatsoa bohareng ka seretse sa samente. Lesela la samente le lumellana le maemo a machaba a ISO4179, ho netefatsa hore seretse se matla ebile se boreleli. Ho roala enjene ho ke ke ha oa kapa ho silafala, 'me botenya ba eona bo ntse bo tiisa hore metsi a nooang a fetisoang ke liphaephe a fumana tšireletso e ntle.

4. Tšireletso e sireletsang:

Ho fafatsa zinki ka liphaephe tsa tšepe tsa ductile ho ka sireletsa liphaephe ka matla ka phello ea electrochemical ea zinki le tšepe. Ka pente e phahameng ea chiorinated resin, liphaephe li tla fumana tšireletso e matlafalitsoeng e thibelang kutu. Ho fafatsa zinki ka holim'a phaephe ka 'ngoe ha ho ka tlase ho 130g/m², 'me ho latela maemo a ISO8179. Re ka boela ra eketsa botenya ba ho fafatsa ka zinki kapa ho fafatsa zinki & aluminium alloy layer ho latela tlhoko ea bareki.

Likaroloana

Pipe ea tšepe ea ductile ke mofuta oa phala ea tšepe e entsoeng ka tšepe. Mabapi le boleng, boemo ba spheroidization ba liphaephe tsa tšepe tse entsoeng ka tšepe bo hlokeha ho laoloa maemong a 1-3 (sekhahla sa spheroidization> 80%), kahoo ho ntlafatsa thepa ea mochine ka boeona, e nang le mohloli oa tšepe le thepa ea tšepe. Pipe ea tšepe ea annealed ductile e na le sebopeho sa metallographic ea ferrite e nang le pearlite e nyenyane, e nang le thepa e ntle ea mochine, ts'ebetso e ntle ea anti-corrosion, ductility e ntle, phello e ntle ea ho tiisa, ho kenya habonolo, 'me e sebelisoa haholo-holo bakeng sa phepelo ea metsi, phetisetso ea khase, lipalangoang tsa oli, joalo-joalo likhoebong tsa masepala le tsa indasteri.

Ho na le palo e itseng ea graphite e chitja e ajoang holim'a matrix a ferrite le pearlite. Ho itšetlehile ka bophara ba lebitso le litlhoko tsa ho lelefatsa, karolo ea ferrite le pearlite mohahong oa matrix e fapana. Karolelano ea pearlite ka li-diameter tse nyane hangata ha e fete 20%, athe ka bophara bo boholo hangata e laoloa ke hoo e ka bang 25%.

Kopo

Liphaephe tsa tšepe tsa ductile li fumaneha ka bophara ba lisenthimithara tse 80 ho isa ho 1600mm 'me li loketse phetiso ea metsi a nooang le ho ajoa (ho latela BS EN 545) le likhoerekhoere (ho latela BS EN 598). Ntho ea eona e phahameng ea tšireletso le bokhoni ba ho amohela motsamao oa fatše e etsa hore e be thepa e loketseng ea liphaephe bakeng sa mefuta e mengata ea likopo.

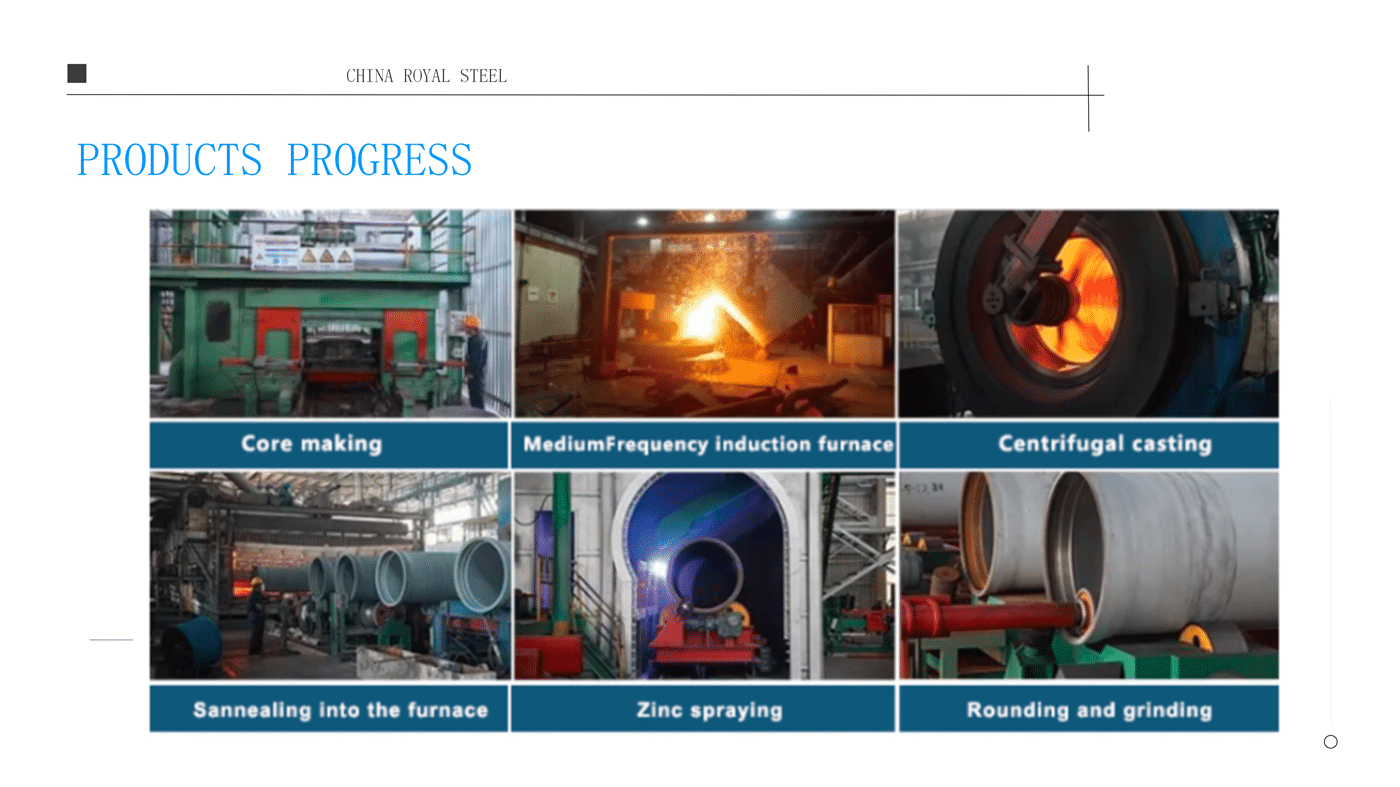

Mokhoa oa Tlhahiso

Packaging & Shipping

LBH

1. Nka fumana mantsoe a qotsitsoeng joang ho uena?

U ka re siela molaetsa, 'me re tla araba molaetsa o mong le o mong ka nako.

2.Na u tla tlisa thepa ka nako?

E, re tšepisa ho fana ka lihlahisoa tsa boleng bo holimo le ho fana ka thepa ka nako. Botšepehi ke molao oa k'hamphani ea rona.

3.Na nka fumana disampole pele odara?

Ehlile ho joalo. Hangata lisampole tsa rona ke tsa mahala, re ka li hlahisa ka lisampole tsa hau kapa lits'oants'o tsa tekheniki.

4.Lipehelo tsa hau tsa tefo ke life?

Nako ea rona e tloaelehileng ea ho patala ke 30% depositi, 'me re phomola khahlanong le B/L. EXW, FOB, CFR, CIF.

5.Na u amohela tlhahlobo ea motho oa boraro?

Ee ruri re amohela.

6.Re tšepa k'hamphani ea hau joang?

Re sebetsa ka ho khetheha khoebong ea tšepe ka lilemo tse ngata re le mofani oa thepa ea khauta, ntlo-khōlō e sebakeng sa setereke sa Tianjin, re amohelehile ho etsa lipatlisiso ka litsela leha e le life, ka mekhoa eohle.