Borokho/Fektheri/Bobolokelo ba Sejoale-joale/Setsi sa Mabenkele Sebopeho sa Tšepe Kaho ea Boenjiniere

Karolo kapa karolo ka 'ngoe hangata e hokahantsoe ka li-weld, liboutu kapa li-rivets. Ka lebaka la boima ba eona bo bobebe le kaho e bonolo, e sebelisoa haholo lifekthering tse kholo, libakeng tsa mosebetsi, mehahong e meholo haholo, marokhong le masimong a mang. Meaho ea tšepe e na le mafome. Ka kakaretso, mehaho ea tšepe e hloka ho tlosoa mafome, ho pentoa ka galvanized kapa ho pentoa, 'me e tlameha ho hlokomeloa khafetsa.

*Romella imeile ho[email protected]ho fumana khotheishene bakeng sa merero ea hau

| Lebitso la sehlahisoa: | Moaho oa Tšepe Sebopeho sa Tšepe |

| Lintho tse bonahalang: | Q235B , Q345B |

| Foreimi e ka sehloohong: | Boreleli ba tšepe bo nang le sebopeho sa H |

| Purlin: | C,Z - purlin ea tšepe e nang le sebopeho |

| Marulelo le lebota: | 1. lakane ea tšepe e entsoeng ka masenke; 2. diphanele tsa sandwich tsa boya ba lefika; 3. Liphanele tsa sandwich tsa EPS; 4. diphanele tsa sandwich tsa boya ba khalase |

| Monyako: | 1. Heke ea ho pitikisa 2. Lemati le thellang |

| Fensetere: | Tšepe ea PVC kapa motsoako oa aluminium |

| Molomo o ka tlase: | Phaephe e chitja ea PVC |

| Kopo: | Mefuta eohle ea li-workshop tsa indasteri, ntlo ea polokelo, moaho o molelele |

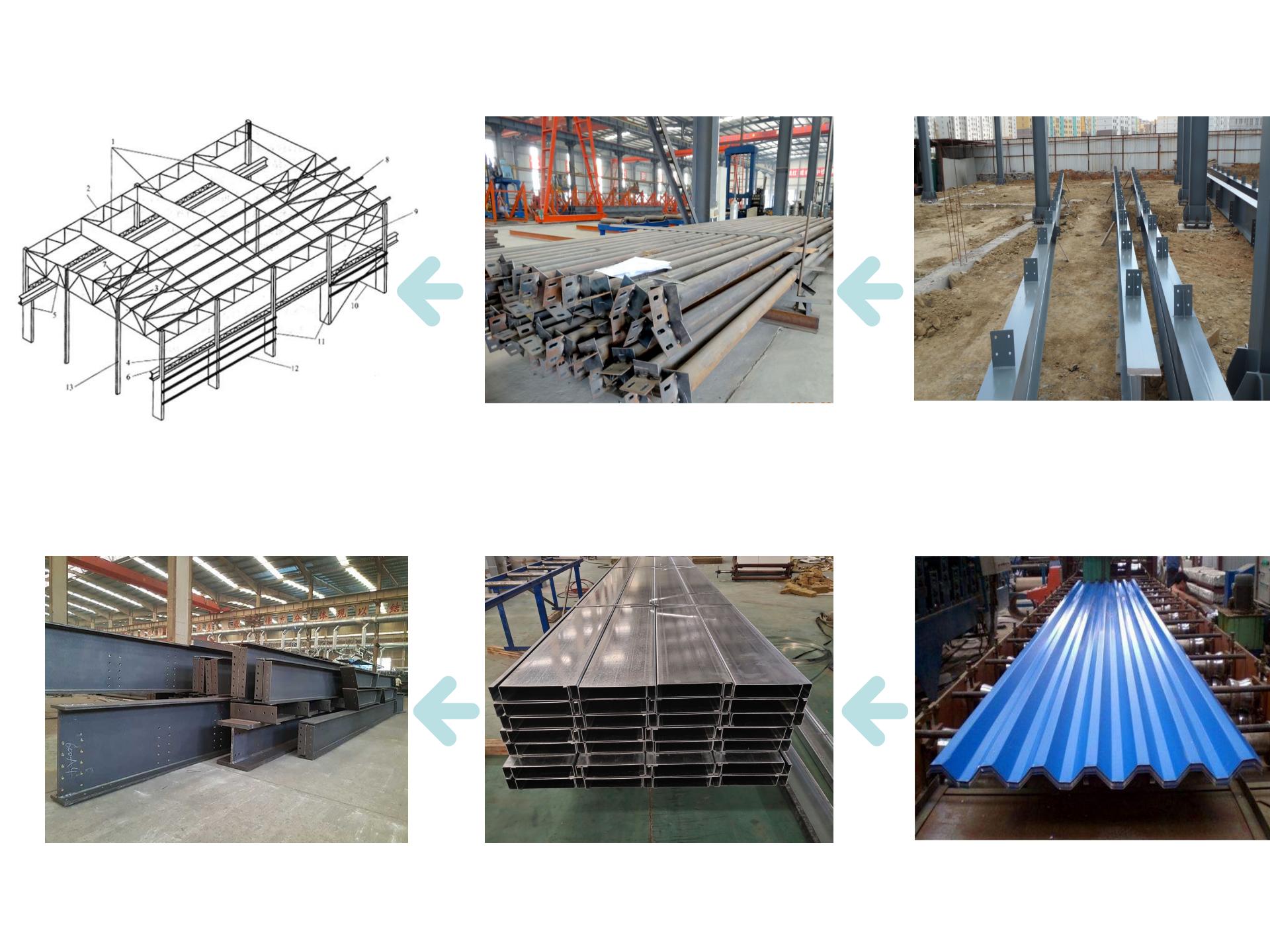

Mokhoa oa Tlhahiso ea Sehlahisoa

MOLEMO

1. Ho jara moroalo: Litšiea tsa tšepe le maballo a tšepe ka har'aSebopeho sa Tšepe Moaho oa Tšepeba ikarabella bakeng sa ho jara boima le mojaro oa moaho oohle.

2. Botsitso: Moaho oa fektheri oa sebopeho sa tšepe o boloka botsitso bo lekanyelitsoeng ba karolo ka 'ngoe ka lihokelo lipakeng tsa likarolo.

3. Khanyetso ea tšisinyeho ea lefatše: Ntlafatsa khanyetso ea tšisinyeho ea lefatše ea moaho ka moralo oa sebopeho sa moaho oa fektheri ea sebopeho sa tšepe le liprofaele tsa likarolo.

4. Boloka thepa: Meaho ea fektheri ea sebopeho sa tšepe e ka fokotsa haholo tšebeliso ea thepa ea kaho ea setso joalo ka konkreite, e leng se bolokang litšenyehelo tsa kaho le mehloli ea tikoloho.

5. Kaho e potlakileng: Ka lebaka la likarolo tse entsoeng esale pele, mehaho ea sebopeho sa tšepe e ka hahuoa kapele ho feta mekhoa ea kaho ea setso.

Ka bokhutšoanyane, moaho oa fektheri oa sebopeho sa tšepe o entsoe ka likarolo tsa tšepe le thepa e 'ngoe. O na le mesebetsi ea bohlokoa ea ho jara mojaro, botsitso le ho hanela litšisinyeho tsa lefatše, 'me o na le melemo ea ho boloka thepa le kaho e potlakileng.

DEPOSITO

Tšepe Sebopeho sa polokeloke sebopeho se entsoeng ka thepa ea tšepe 'me ke e 'ngoe ea mefuta e meholo ea meaho ea meaho. Sebopeho sena se entsoe haholo-holo ka maballo a tšepe, litšiea tsa tšepe, li-trusses tsa tšepe le likarolo tse ling tse entsoeng ka lipoleiti tsa tšepe tse bōpehileng joaloka tšepe le tšepe, 'me se amohela mekhoa ea ho tlosa mafome le ea ho loantša mafome joalo ka silanization, manganese phosphating e hloekileng, ho hlatsoa le ho omisa, le galvanizing. Karolo kapa karolo ka 'ngoe hangata e hokahantsoe ka li-welds, libolt kapa li-rivets. Ka lebaka la boima ba eona bo bobebe le kaho e bonolo, e sebelisoa haholo lifekthering tse kholo, libakeng tsa boikhathollo, mehahong e meholo haholo, marokhong le masimong a mang. Meaho ea tšepe e na le tšekamelo ea ho rusa. Ka kakaretso, mehaho ea tšepe e hloka ho tlosoa mafome, ho penta kapa ho penta, 'me e tlameha ho hlokomeloa khafetsa.

TLHAHLOBO EA SEHLAHISOA

Taba ea pele, litšobotsi tsa mechini tsaDibopeho tsa Tshepelia lekoa, e leng se hlokang liteko tsa ho tsitlella le ho kobeha, 'me ka linako tse ling liteko tsa ts'ebetso ea tataiso ea tšusumetso le botenya. Sena se netefatsa hore poleiti ea tšepe e na le matla le ho tiea ho lekaneng ho mamella mojaro o hlokoang ke moralo.

Taba ea bobeli, litšobotsi tsa mechini tsa thepa ea ho tjheseletsa lia lekoa, tse kenyeletsang haholo-holo tlhahlobo ea lik'hemik'hale le teko ea tšusumetso ea ho tensile. Sena se netefatsa hore boleng ba thepa ea ho tjheseletsa bo tsitsitse 'me bo ka fihlela litlhoko tsa matla le ho tiea ha ho tjheseletsa.

Tlhahlobo ea ts'ebetso ea ho tjheseletsa ea meaho ea tšepe ke ho fumana hore na ts'ebetso ea ho tjheseletsa e ea khoneha le hore na e tla sebetsa hantle hakae. Ho lemoha liphoso tsa ho tjheseletsa ho etsoa ka mokhoa oa ho lemoha liphoso tsa ultrasonic, o arotsoeng ka mefuta e 'meli: tlhahiso ea fektheri le ho kenngoa sebakeng seo. Karolelano ea tlhahlobo e sa reroang hangata ke tlhahlobo ea 100% ea li-weld tsa boemo ba pele le tlhahlobo ea 20% ea li-weld tsa boemo ba bobeli ho netefatsa boleng ba li-weld.

MORERO

Khamphani ea rona hangata e romela kantle ho nahaMeaho ea Tšepe S235jrlihlahisoa ho ea Amerika le linaheng tsa Asia Boroa-bochabela. Re nkile karolo ho e 'ngoe ea merero Amerika e nang le sebaka se ka bang lisekoere-mithara tse 543,000 le tšebeliso e felletseng ea lithane tse ka bang 20,000 tsa tšepe. Kamora hore projeke e phethoe, e tla ba moaho oa tšepe o kopanyang tlhahiso, bolulo, ofisi, thuto le bohahlauli.

KOPO

Tšimong ea litora,Ntlo ea polokelo ea Meaho ea TšepeBoenjiniere bo sebelisoa haholo lits'ebetsong tsa meaho tse kang litora tse telele, litora tsa TV, litora tsa antenna le li-chimney. Meaho ea tšepe e na le melemo ea matla a phahameng, bobebe le lebelo le potlakileng la kaho, e leng se etsang hore e sebelisoe haholo lefapheng la litora.

Lefapheng la marokho, boenjiniere ba meaho ea tšepe bo sebelisoa haholo lits'ebetsong tsa meaho ea marokho tse kang marokho a bolelele bo bolelele, marokho a hahiloeng ka thapo, marokho a emisitsoeng le marokho a li-arch. Meaho ea tšepe e na le melemo ea matla a phahameng, ho tšoarella hantle le kaho e bonolo, e leng se etsang hore e sebelisoe haholo lefapheng la marokho.

Lefapheng la kaho, boenjiniere ba meaho ea tšepe bo sebelisoa haholo litsamaisong tsa meaho e melelele, mehaho e telele, libaka tsa lipapali, liholo tsa lipontšo le mehaho e meng. Melemo ea meaho ea tšepe e kang matla a phahameng, bobebe le lebelo le potlakileng la kaho e etsa hore e sebelisoe haholo tšimong ea kaho.

HO PHAKISA LE HO ROMELA

Qubu ea tšepe e lokela ho ba matla, e ke ke ea lumella qubu ea tšepe ho sisinyeha pele le morao, e le ho qoba hore ponahalo ea qubu ea tšepe e se ke ea senyeha, qubu ea tšepe e tsamaisoang ka kakaretso e tla nka lijana, thepa e ngata, LCL jj. Ho paka meaho ea tšepe bakeng sa ho romelloa ke ts'ebetso ea bohlokoa haholo, 'me haeba e sa eloe hloko, thepa e ka lahleha kapa ea senyeha. Ka hona, ha ho pakoa meaho ea tšepe bakeng sa ho romelloa, hoa hlokahala ho netefatsa hore thepa ea ho paka e fihlela maemo, sephutheloana se tiile ebile se tiile, ponahalo e boreleli, e hanela mongobo, e hanela ho tšoha ebile e hanela ho tsofala. Haholo-holo bakeng sa thepa e ngata, e boetse e hloka ho qhaqhoa le ho pakoa. Ts'ebetsong ea 'nete, tlhokomelo e lokela ho lefshoa ts'ebetsong e tloaelehileng le ho latela melao e amehang ho netefatsa hore thepa e tsamaisoa ka mokhoa o sireletsehileng le o tsitsitseng.

MATLA A K'hamphani

E entsoe Chaena, tšebeletso ea boemo ba pele, boleng bo holimo, e tsebahala lefatšeng ka bophara

1. Phello ea sekala: Khamphani ea rona e na le ketane e kholo ea phepelo le fektheri e kholo ea tšepe, e fihlelang liphello tse kholo lipalangoang le theko, 'me e fetoha k'hamphani ea tšepe e kopanyang tlhahiso le lits'ebeletso.

2. Mefutafuta ya dihlahiswa: Mefutafuta ya dihlahiswa, tshepe efe kapa efe eo o e batlang e ka rekwa ho rona, haholo-holo e sebetsanang le meaho ya tshepe, di-rails tsa tshepe, di-sheet pile tsa tshepe, di-bracket tsa photovoltaic, tshepe ya kanale, di-coil tsa tshepe tsa silicon le dihlahiswa tse ding, e leng se etsang hore e tenyetsehe haholoanyane. Khetha mofuta wa sehlahiswa o lakatsehang ho fihlela ditlhoko tse fapaneng.

3. Phepelo e tsitsitseng: Ho ba le mohala o tsitsitseng oa tlhahiso le ketane ea phepelo ho ka fana ka phepelo e tšepahalang haholoanyane. Sena se bohlokoa haholo ho bareki ba hlokang tšepe e ngata.

4. Tšusumetso ea lets'oao: E na le tšusumetso e phahameng ea lets'oao le 'maraka o moholo

5. Tšebeletso: Khamphani e kholo ea tšepe e kopanyang mokhoa oa ho iketsetsa, lipalangoang le tlhahiso

6. Tlholisano ea theko: theko e utloahalang

*Romella imeile ho[email protected]ho fumana khotheishene bakeng sa merero ea hau

KETO EA BAREKI