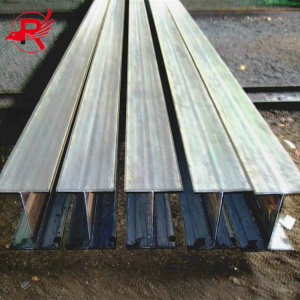

Bonolo ba H Beam ea Tšepe e Sebelisoa Haholo Chaena

libalaka tsa tšepe tsa he arotsoe haholo ka thepa e 'meli, e 'ngoe ke tšepe ea sebopeho sa khabone ea Q235B, e 'ngoe ke tšepe ea alloy ea khabone ea Q345B. Jwalo ka thepa ea bohlokoa ea kaho, tšepe e tloaelehileng ea Amerika e bōpehileng joaloka H e sebelisoa haholo mehahong e fapaneng ea boenjiniere. E le ho netefatsa polokeho, botšepehi le katleho ea tšepe e bōpehileng joaloka H nakong ea lipalangoang, litlhoko tsa ho tlisa le ho paka li bohlokoa haholo. Sengoloa sena se tla hlahisa ka botlalo litlhoko tsa ho tlisa le ho paka tsa li-H-beams tse tloaelehileng tsa Amerika e le hore basebetsi ba amehang ba ka li latela ts'ebetsong ea 'nete.

Mokhoa oa Tlhahiso ea Sehlahisoa

1. Tokisetso ea pele: ho kenyeletsoa le theko ea thepa e tala, tlhahlobo ea boleng le tokiso ea thepa. Hangata thepa e tala ke tšepe e qhibilihisitsoeng e hlahisoang ka ho etsa tšepe ea sebōpi sa graphitization ea boleng bo holimo kapa ho etsa tšepe ea sebōpi sa motlakase, e kenngoang tlhahisong kamora tlhahlobo ea boleng.

2. Ho qhibilihisa: Tšela tšepe e qhibilihisitsoeng ka har'a sesebelisoa sa ho fetola tšepe ebe u eketsa tšepe e khutlisitsoeng kapa ea kolobe bakeng sa ho etsa tšepe. Nakong ea ts'ebetso ea ho etsa tšepe, tekanyo ea khabone le mocheso oa tšepe e qhibilihisitsoeng li laoloa ka ho fetola tekanyo ea graphitizing agent le ho foka oksijene ka ontong.

3. Billet ea ho lahla e tsoelang pele: Billet ea ho etsa tšepe e tšeloa ka har'a mochini o lahlang o tsoelang pele, 'me metsi a phallang a tsoang mochining o lahlang o tsoelang pele a kenngoa ka har'a kristale, e leng se lumellang tšepe e qhibilihisitsoeng ho tiea butle-butle ho etsa billet.

4. Ho phutholla ka ho chesa: Sekotwana sa ho lahla se tswelang pele se phutholla ka ho chesa ka hara yuniti ya ho phutholla ka ho chesa ho etsa hore se fihle boholo bo boletsweng le sebopeho sa jeometri.

5. Qetella ho phutholla: Billet e phuthollang e chesang e phethiloe ho phutholla, 'me boholo le sebopeho sa billet li etsoa hore li nepahale haholoanyane ka ho fetola liparamente tsa tšilo ea ho phutholla le ho laola matla a ho phutholla.

6. Ho Pholisa: Tšepe e felileng e pholisoa ho fokotsa mocheso le ho lokisa litekanyo le thepa.

7. Tlhahlobo le sephutheloana sa boleng: Tlhahlobo ea boleng ba lihlahisoa tse felileng le sephutheloana ho latela boholo le litlhoko tsa bongata.

BOHOLO BA SEHLAHISOA

| LITLHAKISO TSAH-BRIAM | |

| 1. Boholo | 1) Botenyas:5-34mmkapa e etselitsoeng motho ka mong |

| 2) Bolelele:6-12m | |

| 3) Botenya ba webo:6mm-16mm | |

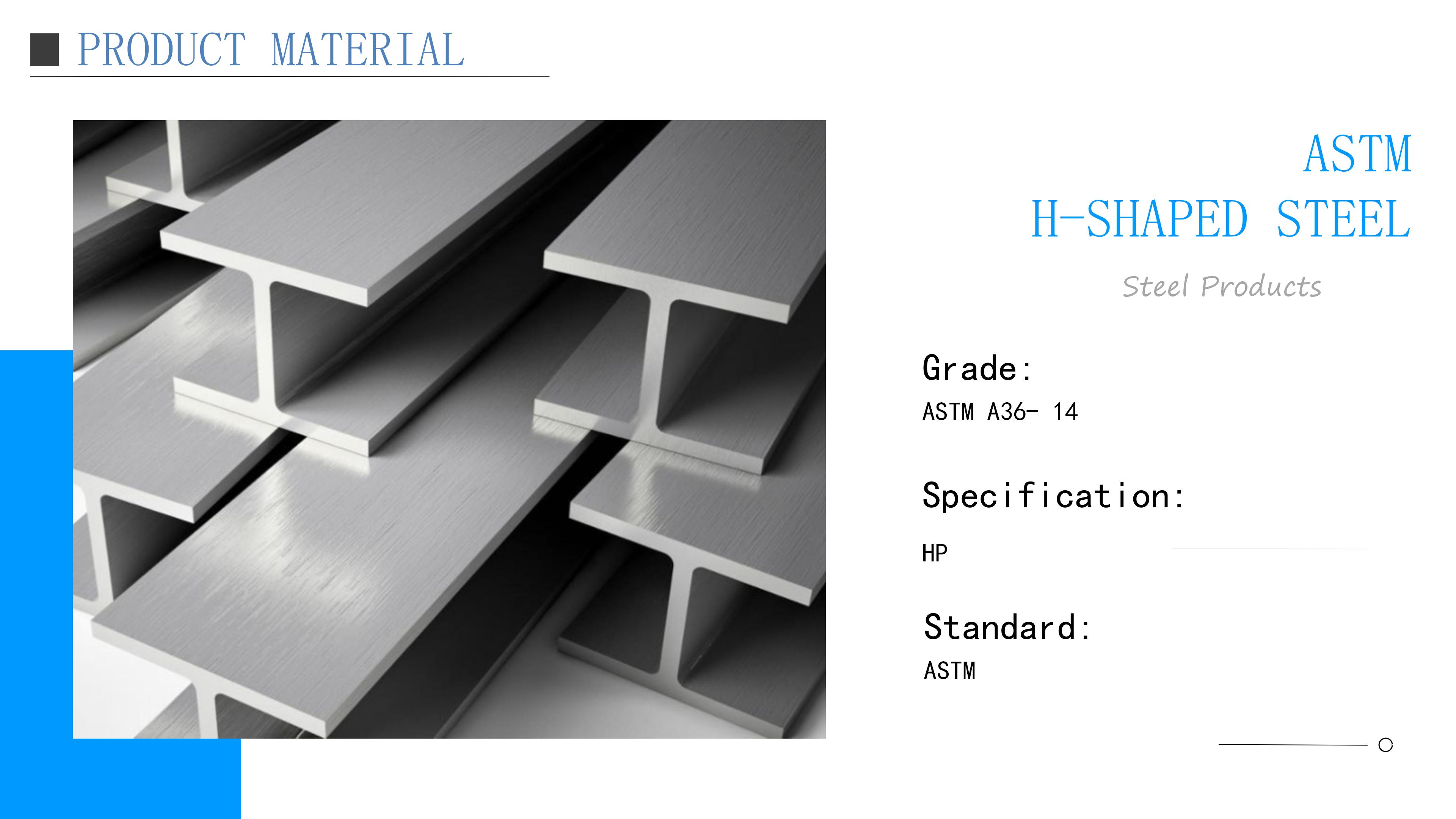

| 2. Maemo a Tloaelehileng: | JIS ASTM DIN EN GB |

| 3. Thepa | Q195 Q235 Q345 A36 S235JR S335JR |

| 4. Sebaka sa fektheri ea rona | Tianjin, China |

| 5. Tšebeliso: | 1) moaho o phahameng oa liindasteri |

| 2) Meaho e libakeng tse kotsing ea ho sisinyeha ha lefatše | |

| 3) marokho a maholo a nang le di-spans tse telele | |

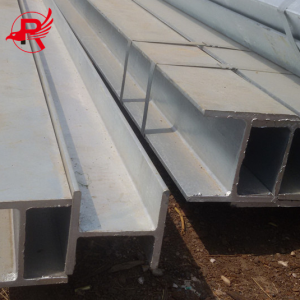

| 6. Ho roala: | 1) Ho hlobola 2) Pente e Ntšo (seaparo sa varnish) 3) galvanized |

| 7. Mokhoa: | hot rolled |

| 8. Mofuta: | Qhobosheane ea pampiri ea mofuta oa H |

| 9. Sebopeho sa Karolo: | H |

| 10. Tlhahlobo: | Tlhahlobo kapa tlhahlobo ea moreki ke motho oa boraro. |

| 11. Thomello: | Setshelo, Sejana se Sengata. |

| 12. Mabapi le Boleng ba Rona: | 1) Ha ho na tshenyo, ha ho na ho kobeha 2) Mahala bakeng sa ho tlotsoa ka oli le ho tšoaea 3) Thepa eohle e ka hlahlojoa ke motho oa boraro pele e romelloa |

| Divis ibn (botebo x idth | Yuniti Boima ba 'mele kg/m) | Sectional ea Sandard Tekanyo (mm) | Karolo Sebaka cm² | ||||

| W | H | B | 1 | 2 | r | A | |

| HP8x8 | 53.5 | 203.7 | 207.1 | 11.3 | 11.3 | 10.2 | 68.16 |

| HP10x10 | 62.6 | 246.4 | 255.9 | 10.5 | 10.7 | t2.7 | 70.77 |

| 85.3 | 253.7 | 259.7 | 14.4 | 14.4 | 127 | 108.6 | |

| HP12x12 | 78.3 | 2992 | 305.9 | 11.0 | 11.0 | 15.2 | 99.77 |

| 93.4 | 303.3 | 308.0 | 13.1 | 13.1 | 15.2 | 119.0 | |

| 111 | 308.1 | 310.3 | 15.4 | 15.5 | 15.2 | 140.8 | |

| 125 | 311.9 | 312.3 | 17.4 | 17.4 | 15.2 | 158.9 | |

| HP14x14% | 108.0 | 345.7 | 370.5 | 12.8 | t2.8 | 15.2 | 137.8 |

| 132.0 | 351.3 | 373.3 | 15.6 | 15.6 | 15.2 | 168.4 | |

| 152.0 | 355.9 | 375.5 | 17.9 | 17.9 | 15.2 | 193.7 | |

| 174.0 | 360.9 | 378.1 | 20.4 | 20.4 | 15.2 | 221.5 | |

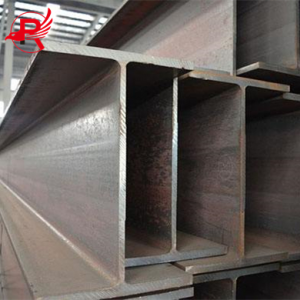

MOLEMO

Tšebeliso ea tšepe ea lehlaseli la h

H-beam ke tšepe ea karolo ea moruo, e nang le boima bo bobebe, matla a phahameng, ho tiea hantle le litšobotsi tse ling, e sebelisoa haholo kahong, borokhong, tlhahisong ea mechini, kahong ea likepe le masimong a mang. Tse latelang ke tšebeliso e khethehileng ea tšepe e bōpehileng joaloka H:

Mehahong ea liindasteri le ea sechaba, hangata e sebelisoa ho etsa maballo, litšiea, lere le likarolo tse ling tse jarang mojaro.

Kahong ea borokho, ka lebaka la bokhoni ba eona bo matla ba ho jara le ho hanyetsa ho kobeha, hangata e sebelisoa ho etsa likarolo tsa tšepe tsa Marokho.

Lefapheng la kaho ea likepe le kaho ea mechini,tšepe ea lehlaseli la he sebelisetsoa ho etsa meaho ea foreimi. 69

Lisebelisoa tsa indasteri, tse kang petrochemical, motlakase le masimo a mang, H beam e sebelisoa bakeng sa meaho ea tšehetso

Mechineng ea temo, litereneng, likoloing, literekeng le masimong a mang, lehlaseli la H le sebelisoa ho etsa litšehetso tsa lehlaseli kapa meaho ea foreimi.

Masimong a likou le litsela tse kholo, tšepe e bōpehileng joaloka H e sebelisoa ho etsa li-bracket tsa lebanta la conveyor le li-bracket tsa ho thibela sephethephethe tse khōlō.

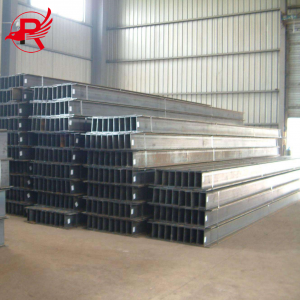

KOPO

Lehlaseli la He ka sebelisoa matlong, mehahong ea sechaba le lifemeng tsa indasteri. Histori ea meaho ea meaho e ka hanela khoholeho ea maemo a leholimo, joalo ka mongobo, ho koloba ha metsi, lehloa le leqhoa, jj. Ka ho sebelisa meaho e se nang meaho, botsitso le ho tšoarella ha meaho ho ka ntlafatsoa haholo.

HO PHAKISA LE HO ROMELA

Sephutheloana:

Beha liqubu tsa maqephe ka mokhoa o sireletsehileng: Beha H-Beam ka har'a qubu e ntle le e tsitsitseng, u netefatse hore li hlophisitsoe hantle ho thibela ho se tsitse. Sebelisa thapo kapa lebanta ho tiisa qubu le ho thibela ho sisinyeha nakong ea lipalangoang.

Sebelisa thepa e sireletsang ea ho paka: Phutha mokoallo oa liqubu tsa maqephe ka thepa e sa keneleng mongobo, joalo ka polasetiki kapa pampiri e sa keneleng metsi, ho li sireletsa hore li se ke tsa pepesehela metsi, mongobo le lintho tse ling tsa tikoloho. Sena se tla thusa ho thibela mafome le mafome.

Ho tsamaisa ka sekepe:

Khetha mokhoa o loketseng oa lipalangoang: Ho latela bongata le boima ba liqubu tsa pampiri, khetha mokhoa o loketseng oa lipalangoang, joalo ka literaka tse bataletseng, lijana, kapa likepe. Nahana ka lintlha tse kang sebaka, nako, litšenyehelo, le litlhoko life kapa life tsa molao bakeng sa lipalangoang.

Sebelisa lisebelisoa tse loketseng tsa ho phahamisa: Ho kenya le ho theola liqubu tsa tšepe tse bōpehileng joaloka U, sebelisa lisebelisoa tse loketseng tsa ho phahamisa tse kang likereine, liforoko, kapa li-loader. Netefatsa hore lisebelisoa tse sebelisitsoeng li na le bokhoni bo lekaneng ba ho sebetsana le boima ba liqubu tsa maqephe ka mokhoa o sireletsehileng.

Tiisa mojaro: Tiisa mokoalo o pakiloeng oa liqubu tsa lilakane koloing ea lipalangoang ka nepo u sebelisa lithapo, litšepe, kapa mekhoa e meng e loketseng ho thibela ho sisinyeha, ho thella, kapa ho oa nakong ea leeto.

MATLA A K'hamphani

E entsoe Chaena, tšebeletso ea boemo ba pele, boleng bo holimo, e tsebahala lefatšeng ka bophara

1. Phello ea sekala: Khamphani ea rona e na le ketane e kholo ea phepelo le fektheri e kholo ea tšepe, e fihlelang liphello tse kholo lipalangoang le theko, 'me e fetoha k'hamphani ea tšepe e kopanyang tlhahiso le lits'ebeletso.

2. Mefutafuta ya dihlahiswa: Mefutafuta ya dihlahiswa, tshepe efe kapa efe eo o e batlang e ka rekwa ho rona, haholo-holo e sebetsanang le meaho ya tshepe, di-rails tsa tshepe, di-sheet pile tsa tshepe, di-bracket tsa photovoltaic, tshepe ya kanale, di-coil tsa tshepe tsa silicon le dihlahiswa tse ding, e leng se etsang hore e tenyetsehe haholoanyane. Khetha mofuta wa sehlahiswa o lakatsehang ho fihlela ditlhoko tse fapaneng.

3. Phepelo e tsitsitseng: Ho ba le mohala o tsitsitseng oa tlhahiso le ketane ea phepelo ho ka fana ka phepelo e tšepahalang haholoanyane. Sena se bohlokoa haholo ho bareki ba hlokang tšepe e ngata.

4. Tšusumetso ea lets'oao: E na le tšusumetso e phahameng ea lets'oao le 'maraka o moholo

5. Tšebeletso: Khamphani e kholo ea tšepe e kopanyang mokhoa oa ho iketsetsa, lipalangoang le tlhahiso

6. Tlholisano ea theko: theko e utloahalang

*Romella imeile ho[email protected]ho fumana khotheishene bakeng sa merero ea hau

LBH

1. Nka fumana khotheishene joang ho tsoa ho uena?

O ka re siela molaetsa, 'me re tla araba molaetsa o mong le o mong ka nako.

2. Na o tla isa thepa ka nako?

E, re tšepisa ho fana ka lihlahisoa tsa boleng bo holimo le ho li tlisa ka nako. Botšepehi ke molao-motheo oa k'hamphani ea rona.

3.Na nka fumana disampole pele ke odara?

E, ehlile. Hangata disampole tsa rona ha di lefellwe, re ka di hlahisa ka disampole tsa hao kapa ka ditshwantsho tsa botekgeniki.

4. Lipehelo tsa hau tsa tefo ke life?

Nako ea rona ea tefo e tloaelehileng ke depositi ea 30%, 'me karolo e setseng khahlanong le B/L. EXW, FOB, CFR, CIF.

5. Na o amohela tlhahlobo ea motho oa boraro?

E, ruri rea amohela.

6. Re tšepa khamphani ea hau joang?

Re ikhethile khoebong ea tšepe ka lilemo tse ngata re le mofani oa khauta, ntlo-kholo e profinseng ea Tianjin, re amohelehile ho etsa lipatlisiso ka litsela life kapa life, ka mekhoa eohle.