Ts'ebetso ea Tšepe le E Ikhethileng

-

Litepisi tsa Spiral tsa Kantle tsa Mekhoa ea Kajeno ea Litepisi tsa Tšepe bakeng sa Litepisi tsa Kantle

Litepisi tse potileng tsa kantle tsa sejoale-joale ke mofuta oa litepisi tse bolokang sebaka, tsa sejoale-joale le tse sebetsang tse potileng holimo ho potoloha kholomo e bohareng. Li ka sebelisoa mathuleng, mathuleng, mathuleng, lirapeng, kapa e le khokahano ea kantle pakeng tsa libaka tse maemong a fapaneng.

-

Lisebelisoa tsa Tšepe tsa Sebopeho sa ASTM tse Welded H-Beam tse Tloaelehileng bakeng sa Meaho ea Kaho le Tšepe

Likarolo tsa H-Beam ke lihlahisoa tsa tšepe tsa H-beam tse sebetsoang ka ho seha, ho tjheseletsa, ho cheka, ho lokisa bokaholimo le tse ling. Li sebelisoa haholo mohahong oa tšepe, fekthering ea indasteri, mosebetsing oa matsoho, polokelong ea thepa, borokhong le meralong ea motheo e nang le mojaro o boima le botsitso ba sebopeho.

-

ASTM A36 1008 4320 SS400 S235JR Poleiti e Entsoeng e Chesitsoeng e Chesitsoeng ea Tšepe ea Khabone ea MS e Chesitsoeng ka Chekere / Letlapa la Taemane

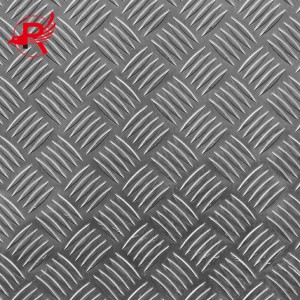

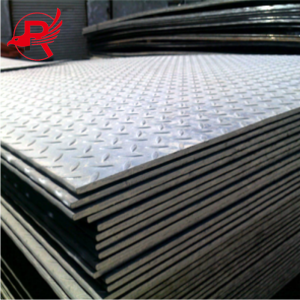

Lipoleiti tsa tšepe tse tšoarellang tse nang le likhutlo tse tšeletseng tse nang le lipaterone tse phahamisitsoeng bakeng sa ho tšoara hantle—li loketse fatše le litepisi tse sireletsehileng tsa indasteri.

-

Poleiti ea Tšepe e Chesang e Felletseng ea Boleng bo Phahameng ea Taemane e Laoloang ka Ntle ho Theolelo e Thibelang ho Theoha e Khabisitsoeng ka Letlapa la Tšepe le Checkered Bakeng sa Mokato

Lipoleiti tsa tšepe tse tšoarellang tse nang le matheba a malelele tse nang le lipaterone tse thibelang ho thella—li loketse hantle bakeng sa fatše le sireletsehileng la indasteri, litsela tsa ho tsamaea le litepisi.

-

Poleiti ea Tšepe ea Khabone ea Astm A36 A252 Poleiti ea Tšepe e nang le Checkered ea Q235

Tšepe ea poleiti ea taemane ke mofuta oa lakane ea tšepe e nang le taemane e phahamisitsoeng kapa paterone e otlolohileng holim'a eona, e etselitsoeng ho ntlafatsa ho tšoara le ho hokela. E sebelisoa hangata bakeng sa fatše ea indasteri, litsela tsa ho tsamaea, litepisi, le lits'ebetso tse ling moo ho hanyetsa ho thella ho hlokahalang. Li fumaneha ka botenya le boholo bo fapaneng, lipoleiti tsena tsa tšepe li ka etsoa ka tšepe ea khabone, tšepe e sa ruseng, kapa litšepe tse ling, li fana ka ho tenyetseha le ho tšoarella bakeng sa libaka tse fapaneng tsa indasteri le tsa khoebo.

-

Poleiti ea Tšepe ea Khabone ea Boleng bo Holimo ea Fektheri e Chesitsoeng e Chesitsoeng ea S235 S275 S355 Poleiti ea Tšepe ea Khabone Bakeng sa Kaho

Lipoleiti tsa tšepe tse nang le matheba a malelele, tse tsejoang hape e le lipoleiti tsa tšepe tse nang le lipaterone kapa lipoleiti tsa tšepe tse sa thelleng, ke maqephe a tšepe a nang le paterone e phahamisitsoeng holim'a tsona. Lipaterone tse tloaelehileng li kenyelletsa libopeho tsa daemane, tse khutlonnetsepa le tse chitja. Lipaterone tsena ha li ntlafatse feela litšobotsi tsa poleiti ea tšepe tse sa thelleng, empa li boetse li fana ka botle bo botle le matla a eketsehileng. Lipoleiti tse joalo tsa tšepe li sebelisoa haholo lipolatefomong tsa indasteri, litepising tsa litepisi, litseleng tsa ho tsamaea, fatše la likoloi, fatše la polokelo ea thepa le libakeng tse ling, tse fanang ka polokeho le ho tšoarella.

-

Letlapa la Tšepe ea Khabone le Chequered la Tšepe ea Khabone ea 4 Mm bakeng sa Lisebelisoa tsa Kaho

Lipoleiti tsa tšepe tse nang le matheba a malelele, tse tsejoang hape e le lipoleiti tsa tšepe tse nang le lipaterone kapa lipoleiti tsa tšepe tse sa thelleng, ke lipaterone tsa tšepe tse nang le paterone e tloaelehileng ea mathule a phahamisitsoeng holim'a tsona. Lipaterone tse tloaelehileng li kenyelletsa libopeho tsa daemane, oval le chitja. Sebopeho sena se ikhethang sa bokaholimo ha se ntlafatse khohlano feela ebile se thibela ho thella, empa hape se fana ka botle bo itseng.

-

Kaho ea Moaho oa Lipoleiti tse Checkered ASTM A36 Q235B Q345B S235JR S355JR Lipoleiti tsa Tšepe tse Chesang tse Metsuoang

Lipoleiti tsa tšepe tse nang le matheba a masesaane, tse tsejoang hape e le lipoleiti tsa taemane kapa lipoleiti tsa ho hatakela, ke lihlahisoa tse khethehileng tsa tšepe tse entsoeng ka mekhoa e phahamisitsoeng ea bokaholimo—haholo-holo taemane kapa libopeho tse otlolohileng—tse entsoeng ka ho phutholla ho chesang, ho hatakela ho batang, kapa ho khabisa. Molemo oa tsona oa mantlha o ts'ebetsong e khahlanong le ho thella ha meetso ena e phahamisitsoeng: ka ho eketsa khohlano ea bokaholimo, li fokotsa likotsi tse thellang ka katleho esita le maemong a metsi, a mafura, kapa a lerōle, e leng se etsang hore e be khetho e shebaneng le polokeho bakeng sa maemo a sephethephethe se phahameng kapa a boima.

-

Ts'ebetso ea ho phunya ka mokhoa o ikhethileng oa Oem Tšebeletso ea Lihlahisoa tsa Hardware ea ho Sebetsa

Likarolo tse sebetsitsoeng ka tšepe, tse tsejoang hape e le likarolo tsa tšepe tse entsoeng ka masela, li bolela likarolo kapa lihlahisoa tse sa phethoang hantle tse entsoeng ka thepa e tala ea tšepe (joalo ka lipoleiti tsa tšepe, liphaephe le libopeho tsa sebopeho) ka mekhoa e kang ho seha, ho hatakela, ho koba, ho tjheseletsa, ho sebetsa ka machining, kalafo ea mocheso le ho qeta bokaholimo, ho fihlela litlhoko tse itseng tsa sebopeho, boholo le ts'ebetso. Hangata li sebelisoa e le likarolo tsa bohlokoa tsa lisebelisoa, mechini, kapa meaho ea boenjiniere.

-

Mochini oa ho itšeha oa Laser Die Fiber Laser Cutting Machine Sheet Metal

tšepe e sehiloeng ka laserke mokhoa oa ho seha o nepahetseng haholo, o sebetsang hantle haholo o sebelisoang haholo ts'ebetsong ea litšepe, polasetiki, lehong le lisebelisoa tse ling. Ho seha ka laser ho sebelisa lehlaseli la laser le matla a mangata, le teteaneng ho qhibilihisa kapa ho etsa hore thepa e be mouoane, e leng se lumellang ho seha ka potlako le ka nepo. Mokhoa ona oa ho seha o na le litšobotsi tse latelang:

Taba ea pele, ho seha ka laser ho na le ho nepahala le botenya bo phahameng haholo, ho nolofalletsang ho seha le ho betla thepa hantle, 'me ho loketse ho etsa likarolo tse nang le libopeho tse rarahaneng le meaho e nepahetseng.

Taba ea bobeli, ho seha ka laser ho potlakile ebile ho na le katleho e phahameng ea tlhahiso. Lisebelisoa tsa ho seha ka laser li ka tsamaea le ho seha kapele, e leng se etsang hore li lokele tlhahiso e phahameng le ts'ebetso e sebetsang hantle.

Ho phaella moo, ho seha ka laser ho na le tshusumetso e nyane hodima thepa mme sebaka se amehileng ke mocheso se senyenyane. Ha ho bapiswa le mekgwa ya setso ya ho seha, ho seha ka laser ho ka fokotsa ho fetoha le ditlamorao tsa mocheso mme ha boloka thepa ya pele ya thepa.

Ho seha ka laser ho loketse thepa e fapaneng, ho kenyeletsoa le tšepe, polasetiki, khalase, letsopa, jj., mme ka hona ho sebediswa haholo difofaneng, tlhahisong ya dikoloi, disebedisweng tsa elektroniki le diindastering tse ding.

Ka bokhutšoanyane, ho seha ka laser, e le mokhoa oa ho seha o nepahetseng haholo le o sebetsang hantle, ho fana ka litharollo tsa ho seha ka nepo bakeng sa maemo ohle a bophelo 'me e se e le e' ngoe ea lits'ebetso tsa bohlokoa le tsa bohlokoa tlhahisong ea sejoale-joale.

-

Tšebeletso ea ho Welding ea Tšepe ea Tšepe e Ikhethileng le ho Seha Laser Likarolo tsa ho Stamping Ts'ebetso ea Tšepe ea Sheet

Ho tjheseletsa ke mokhoa o tloaelehileng oa tlhahiso o sebelisoang ho kopanya tšepe kapa thepa ea polasetiki hammoho ka ho li qhibilihisa, ho li tiisa kapa ho li hatella hammoho. Mekhoa ea ho tjheseletsa e sebelisoa hangata ho etseng likarolo tsa meaho, liphaephe, likepe le lihlahisoa tse ling, hammoho le mosebetsing oa tokiso le tlhokomelo.

-

Ho Seha Metsi a Metsi a sa Hlakoleng OEM Likarolo tsa ho Seha Tšepe tse Ikhethileng Tšepe ea Carbon Tšepe e sa Hlakoleng 3/4/5 Axis CNC Machining

Ho seha Waterjet ke theknoloji e tsoetseng pele ea ho seha ka serame e sebelisang molapo o nang le khatello e phahameng ea metsi (hangata o hatelloang ho fihlela ho 30,000–90,000 psi) - hangata e tsoakoa le likaroloana tse khorofo tse kang garnet bakeng sa thepa e thata - ho seha, ho bopa, kapa ho betla mefuta e mengata ea mesebetsi. Jwalo ka ts'ebetso e batang, e qoba ho sotha mocheso, ho thatafala ha thepa, kapa liphetoho tsa lik'hemik'hale thepang e sehiloeng, e leng se etsang hore e be e loketseng lits'ebetso tse amang mocheso kapa tse nepahetseng haholo. E bontša ho tenyetseha ho matla, e khona ho sebetsana le thepa e kang tšepe (tšepe, aluminium, titanium), lejoe, khalase, liseramike, metsoako, esita le lijo, ka bokhoni ba ho seha libopeho tse rarahaneng (mohlala, lipaterone tse rarahaneng, mathoko a kobehileng) le mathoko a teteaneng (ho fihlela ho mashome a lisenthimithara) ha e ntse e boloka mathoko a sehiloeng a boreleli le ho nepahala ho hoholo. E sebelisoa haholo liindastering ho kenyeletsoa le lifofane (bakeng sa likarolo tsa tšepe tse nepahetseng), likoloi (bakeng sa likarolo tse ikhethileng), meralo (bakeng sa likarolo tsa mekhabiso ea majoe/khalase), le tlhahiso (bakeng sa ts'ebetso ea thepa e kopaneng), ho seha ha metsi le hona ho ikhetha ka lebaka la botsoalle ba eona tikolohong - ha e hlahise mosi o chefo kapa litšila tse feteletseng, ho lumellana le litlhoko tsa sejoale-joale tsa tlhahiso e tala.