Lisebelisoa tsa Kaho tsa Tšepe Mofuta o Chesang oa U Mofuta oa Leqephe la Tšepe Mofuta oa 2 Mofuta oa 3 Poleiti ea Tšepe Bakeng sa Phaephe ea Leqephe

BOHOLO BA SEHLAHISOA

| Lebitso la sehlahisoa | |

| E tloaelehileng | AiSi, ASTM, DIN, GB, JISEN10249, EN10248, JIS A 5523 le JIS A 5528, ASTM A328 / ASTM A328M |

| Bolelele | 9 12 15 20 m ha ho hlokahala. 24m |

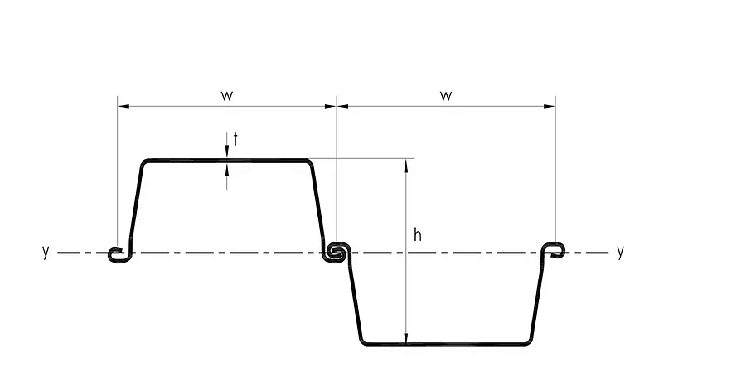

| Bophara | 400-750mm ha ho hlokahala |

| Botenya | 6-25mm |

| Thepa | Q234B/Q345B JIS A5523/SYW295,JISA5528/SY295,SYW390,SY390 ect. |

| Sebopeho | Liprofaele tsa katiba tsa U,Z,L,S,Pan,Flat, |

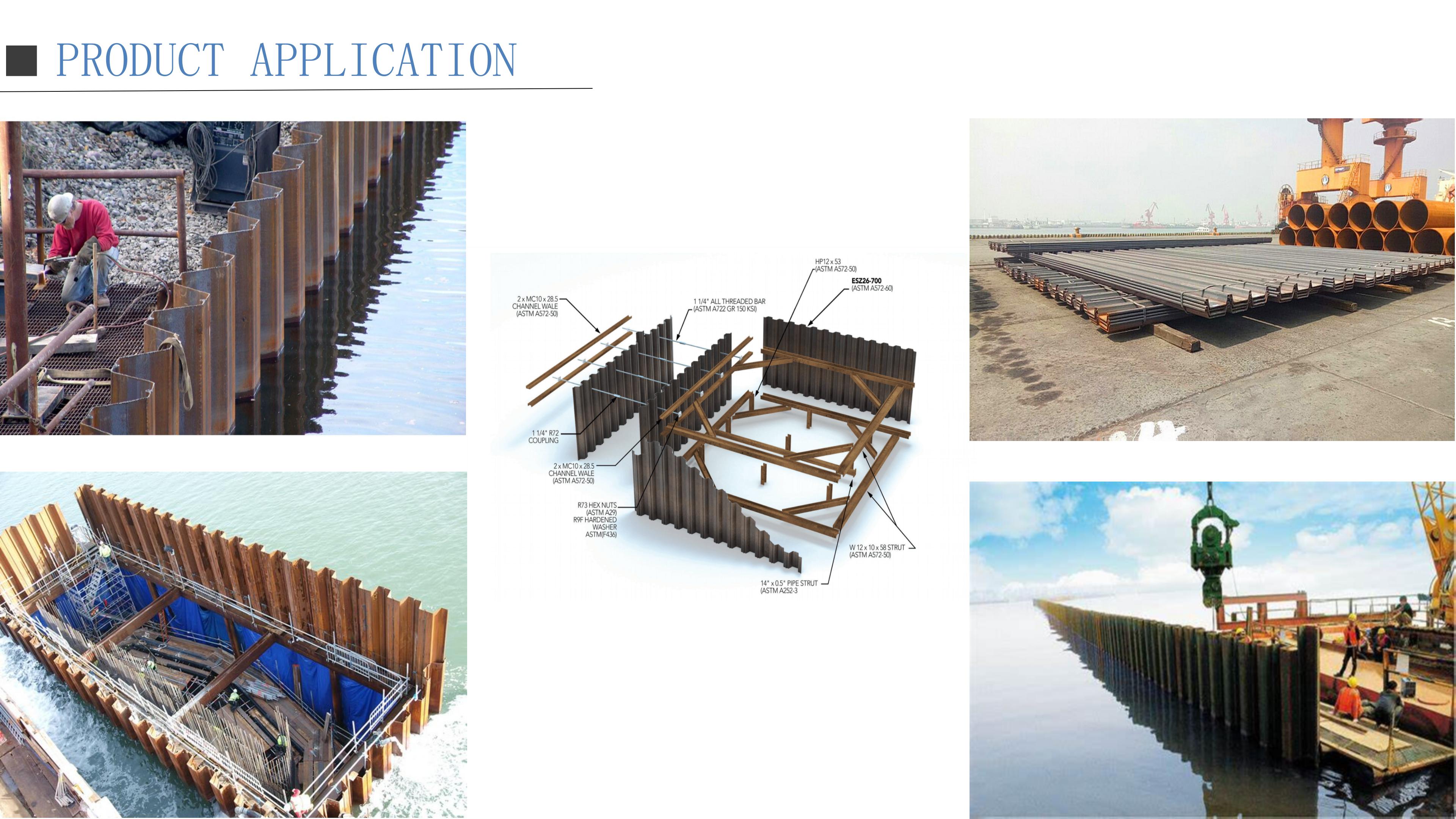

| Kopo | Cofferdam/Ho fapoha le ho laola likhohola tsa noka/ Terata ea sistimi ea kalafo ea metsi/Tšireletso ea moroallo Lebota/ Lerako le sireletsang/Lebōpo la leoatle/Likotopo tsa kotopo le li-bunker tsa kotopo/ Lebota la Metsi a Thibetsoeng/Lebota la Lithapo/ Leralla le tsitsitseng/ Lebota la ho thiba |

| Sehlopha sa tšepe | SGCC/SGCD/SGCE/DX51D/DX52D/S250GD/S280GD/S350GD/G550/SPCC S275, S355, S390, S430, SY295, SY390, Kereiti ya 50, Kereiti ya 55, Kereiti ya 60, A690 |

| Mokhoa | Li-interlock kapa li-clutch tse entsoeng ka serame |

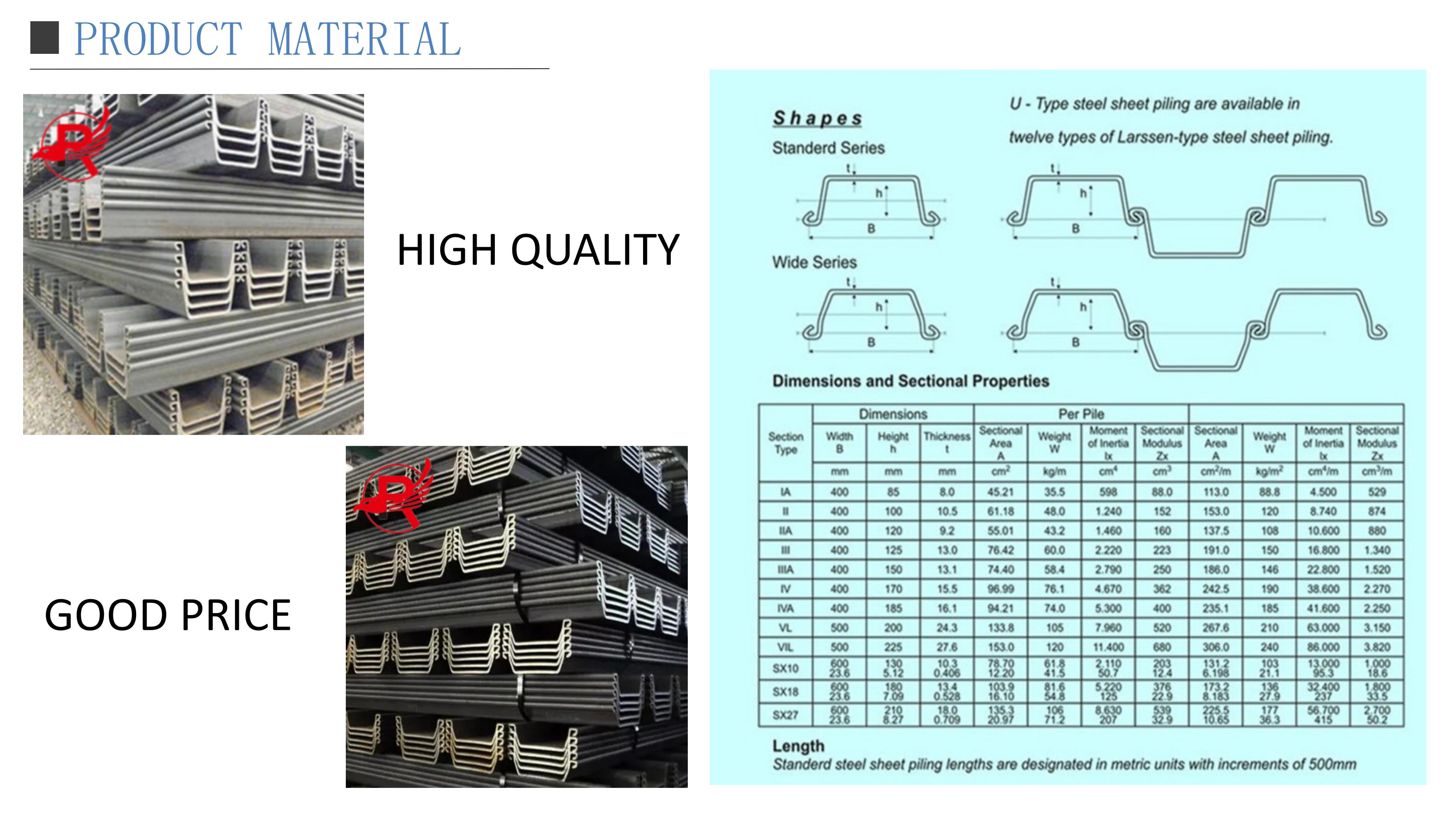

| Karolo | Bophara | Bolelele | Botenya | Sebaka se Tšeletseng | Boima ba 'mele | Modulus ea Karolo e Tenyetsehang | Motsotso oa Bofokoli | Sebaka sa ho Koahela (mahlakore ka bobeli ka qubu) | ||

|---|---|---|---|---|---|---|---|---|---|---|

| (w) | (h) | Sekoahelo (tf) | Web (tw) | Ka Phae | Ka Lebota | |||||

| mm | mm | mm | mm | cm2/m | kg/m | kg/m2 | cm3/m | cm4/m | m2/m | |

| Mofuta oa II | 400 | 200 | 10.5 | - | 152.9 | 48 | 120 | 874 | 8,740 | 1.33 |

| Mofuta oa III | 400 | 250 | 13 | - | 191.1 | 60 | 150 | 1,340 | 16,800 | 1.44 |

| Mofuta oa IIIA | 400 | 300 | 13.1 | - | 186 | 58.4 | 146 | 1,520 | 22,800 | 1.44 |

| Mofuta oa IV | 400 | 340 | 15.5 | - | 242 | 76.1 | 190 | 2,270 | 38,600 | 1.61 |

| Mofuta oa VL | 500 | 400 | 24.3 | - | 267.5 | 105 | 210 | 3,150 | 63,000 | 1.75 |

| Mofuta oa IIw | 600 | 260 | 10.3 | - | 131.2 | 61.8 | 103 | 1,000 | 13,000 | 1.77 |

| Mofuta oa IIIw | 600 | 360 | 13.4 | - | 173.2 | 81.6 | 136 | 1,800 | 32,400 | 1.9 |

| Mofuta oa IVw | 600 | 420 | 18 | - | 225.5 | 106 | 177 | 2,700 | 56,700 | 1.99 |

| Mofuta oa VIL | 500 | 450 | 27.6 | - | 305.7 | 120 | 240 | 3,820 | 86,000 | 1.82 |

*Romella imeile ho[email protected]ho fumana khotheishene bakeng sa merero ea hau

Sebaka sa Modulus ea Karolo

1100-5000cm3/m

Bophara ba Bophara (e le 'ngoe)

580-800mm

Botenya ba mefuta e fapaneng

5-16mm

Maemo a Tlhahiso

BS EN 10249 Karolo ea 1 le ea 2

Mekhahlelo ea Tšepe

SY295, SY390 le S355GP bakeng sa Mofuta oa II ho ea ho Mofuta oa VIL

S240GP, S275GP, S355GP & S390 bakeng sa VL506A ho isa ho VL606K

Bolelele

Bophahamo ba 27.0m

Bolelele bo Tloaelehileng ba Setoko sa 6m, 9m, 12m, 15m

Dikgetho tsa Thomello

Ba le bang kapa ba babeli

Lipara li hlephile, li phuthetsoe kapa li koaletsoe

Lesoba la ho Phahamisa

Ka setshelo (11.8m kapa ka tlase ho moo) kapa Break Bulk

Liaparo tsa Tšireletso ea Ts'enyeho

KOPO

Liqubu tsa Maqephe a Mofuta oa 2: Likarolo le Litšebeliso:

Qubu ea lakane ea 500 x 200 uLi tsebahala ka modulus ea tsona e phahameng ea ho tenyetseha, e leng se lumellang meaho e bolokang e sebetsang hantle le e tsitsitseng. Liqubu tsena tsa maqephe li sebelisoa hangata mererong e amanang le kaho ea meaho e sa feleng, kaha li ka mamella linako tse phahameng tsa ho kobeha le ho fana ka ts'ireletso e ntle ea mobu. Ho phaella moo, moralo oa tsona oa ho hokela o nolofalletsa ho kenngoa kapele le habonolo, e leng se etsang hore e be khetho e ratoang bakeng sa merero e amehang ka nako.

Qubu ea pampiri ea S355GPLi loketse haholo ho haha mabota a tebileng a ho cheka, mabota a khaotsoeng khahlanong le metsi a ka tlas'a lefatše, mabota a ka tlas'a lefatše, le li-abhuroko. Ho tenyetseha ha tsona le ho tenyetseha ha tsona ho li etsa hore li be ntle bakeng sa maemo a fapaneng a kaho, ho netefatsa hore meaho e bolokehile ebile e ka tšeptjoa.

Liqubu tsa Maqephe a Mofuta oa 3: Litšobotsi le Litšebeliso:

Liqubu tsa maqephe a mofuta oa 3 li tsebahala ka ts'ebetso ea tsona e ikhethang ea ho khanna, e leng se etsang hore li lokele libaka tse thata. Liqubu tsena tsa maqephe li na le matla a ho thaepa a holimo ho feta a Mofuta oa 2, e leng se li lumellang ho mamella meroalo e boima le litlhaselo. Liqubu tsa maqephe a Mofuta oa 3 li na le boemo bo pharaletseng, bo ntlafatsang ts'ebetso ea tsona ka kakaretso le botsitso maemong a thata a mobu.

Liqubu tsa maqephe a mofuta oa 3 li sebelisoa hangata mererong ea leoatle le ea lebopong la leoatle, joalo ka mabota a leoatle, liqhobosheane tsa metsi, le meralo ea motheo ea kou. Ho tšoarella ha tsona ho eketsehileng le ho hanyetsa mafome li etsa hore e be khetho e tšepahalang bakeng sa merero e pepesehetseng maemo a thata a tikoloho. Ho feta moo, liqubu tsa maqephe a mofuta oa 3 hangata li ratoa mererong e hlokang litsamaiso tsa ho boloka nakoana ka lebaka la bonolo ba tsona ba ho ntša.

Melemo le Melemo ealiqubu tsa motheo:

Nako e le 1 le e Sebetsang ka Theko e Tlase: Liqubu tsa tšepe tse phutholohileng tsa mofuta oa U tse chesang li etsoa ka boleng bo tsitsitseng 'me li fumaneha habonolo ka boholo le bolelele bo fapaneng. Ho fumaneha hona ho netefatsa theko e bonolo le linako tse sebetsang tsa kaho, ho boloka nako le lisebelisoa tsa bohlokoa.

2 Ho Feto-fetoha ha Meaho: Liqubu tsena tsa maqephe li na le mekhoa e mengata haholo 'me li ka ikamahanya le litlhoko tse fapaneng tsa kaho, ebang ke meaho ea nakoana kapa ea kamehla. Li ka sebelisoa e le mabota a tsoelang pele, li-cofferdam, kapa mabota a khaotsoeng, a fanang ka ho tenyetseha moralong le ho netefatsa botsitso.

3 E Sireletsa Tikoloho: Liqubu tsa tšepe tse phutholohileng tsa mofuta oa U hangata li etsoa ka thepa e sebelisitsoeng hape, e leng se etsang hore e be khetho e tsitsitseng bakeng sa merero ea kaho. Ho feta moo, ho tšoarella le ho tšoarella ha liqubu tsena tsa maqephe ho fokotsa tlhoko ea ho nkeloa sebaka khafetsa, e leng se fokotsang tšusumetso e akaretsang tikolohong.

4 E Matla ebile e Tšoarella: Ts'ebetso ea ho phutholla e chesang e fana ka matla a phahameng le ho tšoarella ho liqubu tsa tšepe tsa mofuta oa U, e li lumellang ho mamella meroalo e boima le ho fana ka ts'epo e ikhethang. Li na le botsitso bo botle ba sebopeho 'me li ka hanela matla a hlahisoang ke mobu, metsi le mabaka a mang a tikoloho.

5 Tlhokomelo e Sebetsang ka Theko e Tlase: Hang ha e kentsoe, liqubu tsa tšepe tse phutholohileng tsa mofuta oa U tse chesang li hloka tlhokomelo e nyane nakong eohle ea ts'ebeletso ea tsona. Ho hanyetsa ha tsona mafome le ho tsofala ka kakaretso ho netefatsa katleho ea nako e telele ea litšenyehelo.

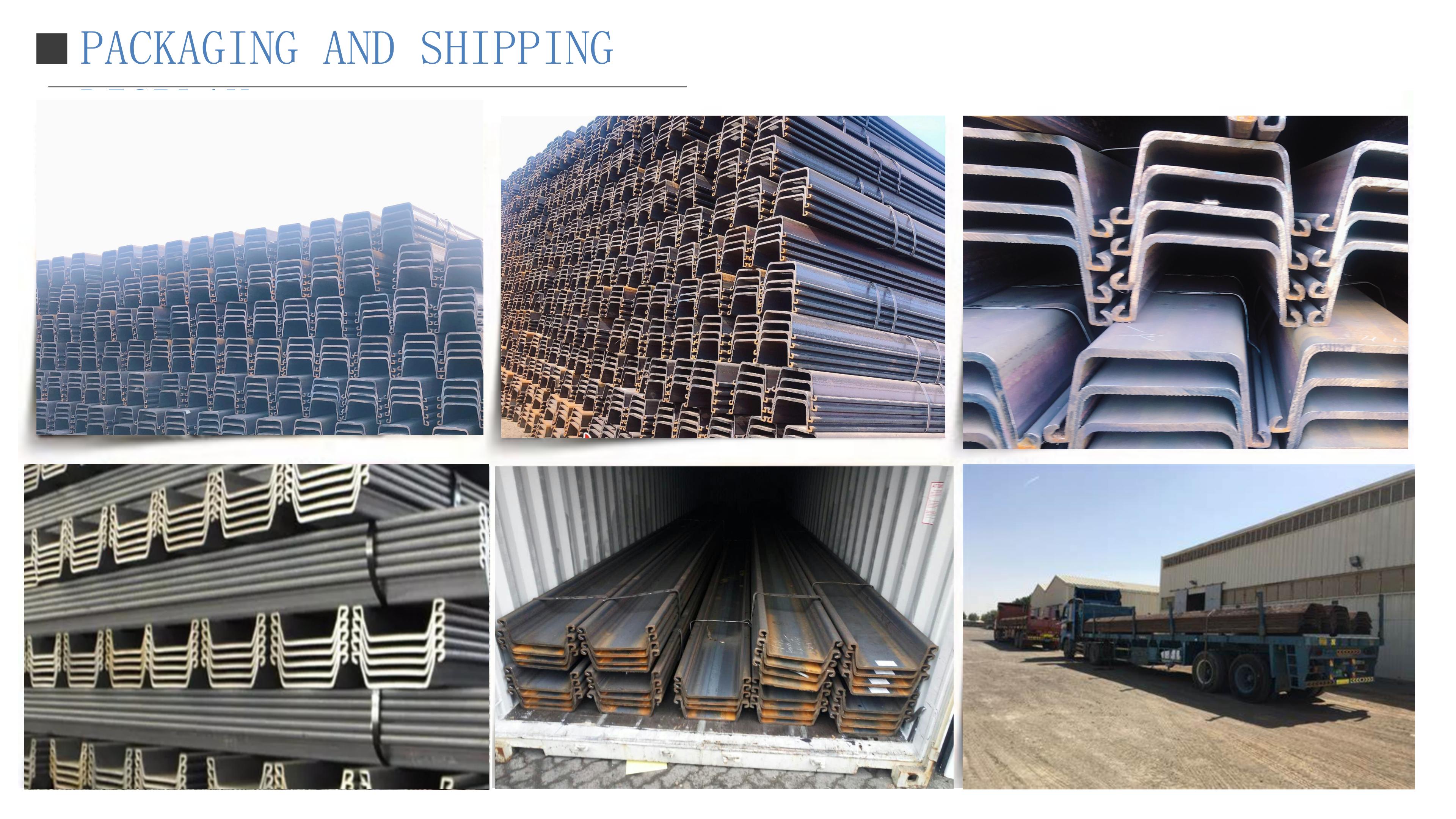

HO PHAKISA LE HO ROMELA

Mokhoa oa ho paka le ho romellaqubu ea lakane ea tšepehangata e kenyelletsa mehato e latelang:

Sephutheloana: Liqubu tsa tšepe hangata li kopanngoa hammoho ka liphutheloana ho sebelisoa marapo a tšepe kapa lithapo. Liphutheloana li tiisitsoe ho thibela ho sisinyeha kapa ho senyeha nakong ea lipalangoang.

Ho ngolwa ha thepa: Sephutheloana se seng le se seng se ngolwa ka tlhahisoleseding e amehang jwalo ka lebitso la sehlahiswa, boholo, bongata le aterese ya moo se yang teng. Sena se thusa ka ho tseba le ho latela nakong ya thomello.

Tšireletso: Ho sireletsa liqubu tsa tšepe mongobong le tšenyo ea 'mele, hangata li phutheloa ka thepa e sa keneleng metsi kapa e hanelang mongobo joalo ka polasetiki kapa li-tarps. Sena se thusa ho thibela mafome le mefuta e meng ea mafome.

Ho kenya: E phuthetsoeho betla liqubuli kenngoa literaka kapa lijaneng tsa ho tsamaisa thepa ho sebelisoa lisebelisoa tse loketseng tsa ho phahamisa thepa. Ho lokela ho ba hlokolosi ha ho ntse ho kenngoa thepa ho netefatsa kabo e nepahetseng ea boima le ho thibela tšenyo efe kapa efe lihlahisoa kapa koloi/setshelo.

Lipalangoang: Khetho ea mokhoa oa lipalangoang e itšetlehile ka lintlha tse fapaneng tse kang moo li eang teng, bongata le potlako. Liqubu tsa tšepe li ka tsamaisoa ka tsela, terene, kapa leoatle. Bakeng sa likepe tse tsamaeang sebaka se selelele kapa tsa machabeng, thepa ea likepe e sebelisoa hangata.

Litokomane tsa Thomello: Litokomane tsohle tse hlokahalang tsa thomello, ho kenyeletsoa le bili ea thepa, lethathamo la ho paka, invoice ea khoebo, le mangolo afe kapa afe a itseng a netefatso kapa litokomane tsa ho latela melao, li lokela ho lokisoa le ho kenyelletsoa le thomello.

Ho bohlokoa ho latela maemo a loketseng a ho paka le melaoana ea ho romella thepa ho netefatsa hore qubu ea tšepe ea mofuta oa U e rokelloang e rokelloa ka mokhoa o sireletsehileng le o nakong e fihlang moo e eang teng. Ho buisana le k'hamphani ea litsebi ea thepa kapa ea ho romella thepa ho ka thusa ho netefatsa hore mekhoa e nepahetseng ea ho paka le ho romella thepa e lateloa.

MATLA A K'hamphani

E entsoe Chaena, tšebeletso ea boemo ba pele, boleng bo holimo, e tsebahala lefatšeng ka bophara

1. Phello ea sekala: Khamphani ea rona e na le ketane e kholo ea phepelo le fektheri e kholo ea tšepe, e fihlelang liphello tse kholo lipalangoang le theko, 'me e fetoha k'hamphani ea tšepe e kopanyang tlhahiso le lits'ebeletso.

2. Mefutafuta ya dihlahiswa: Mefutafuta ya dihlahiswa, tshepe efe kapa efe eo o e batlang e ka rekwa ho rona, haholo-holo e sebetsanang le meaho ya tshepe, di-rails tsa tshepe, di-sheet pile tsa tshepe, di-bracket tsa photovoltaic, tshepe ya kanale, di-coil tsa tshepe tsa silicon le dihlahiswa tse ding, e leng se etsang hore e tenyetsehe haholoanyane. Khetha mofuta wa sehlahiswa o lakatsehang ho fihlela ditlhoko tse fapaneng.

3. Phepelo e tsitsitseng: Ho ba le mohala o tsitsitseng oa tlhahiso le ketane ea phepelo ho ka fana ka phepelo e tšepahalang haholoanyane. Sena se bohlokoa haholo ho bareki ba hlokang tšepe e ngata.

4. Tšusumetso ea lets'oao: E na le tšusumetso e phahameng ea lets'oao le 'maraka o moholo

5. Tšebeletso: Khamphani e kholo ea tšepe e kopanyang mokhoa oa ho iketsetsa, lipalangoang le tlhahiso

6. Tlholisano ea theko: theko e utloahalang

*Romella imeile ho[email protected]ho fumana khotheishene bakeng sa merero ea hau

KETO EA BAREKI

Ha moreki a lakatsa ho etela sehlahisoa, hangata mehato e latelang e ka hlophisoa:

Etsa kopano ea ho etela: Bareki ba ka ikopanya le moetsi kapa moemeli oa thekiso esale pele ho etsa kopano ea nako le sebaka sa ho etela sehlahisoa.

Lokisetsa leeto le tataiswang: Hlophisa ditsebi kapa baemeli ba thekiso e le batataisi ba maeto ho bontsha bareki tshebetso ya tlhahiso, theknoloji le tsamaiso ya taolo ya boleng ba sehlahiswa.

Bontša lihlahisoa: Nakong ea ketelo, bontša lihlahisoa mekhahlelong e fapaneng ho bareki e le hore bareki ba ka utloisisa ts'ebetso ea tlhahiso le maemo a boleng ba lihlahisoa.

Araba lipotso: Nakong ea ketelo, bareki ba ka 'na ba e-ba le lipotso tse fapaneng, 'me motataisi oa bahahlauli kapa moemeli oa thekiso o lokela ho li araba ka mamello le ho fana ka tlhaiso-leseling e nepahetseng ea tekheniki le boleng.

Fana ka disampole: Haeba ho khoneha, disampole tsa dihlahiswa di ka fuwa bareki e le hore bareki ba ka utlwisisa boleng le dibopeho tsa sehlahiswa ka bohlale haholoanyane.

Tekolo: Kamora ketelo, latela kapele maikutlo a bareki mme o hloka ho fa bareki tšehetso le lits'ebeletso tse ling.

LBH

P1: Na u khoebo ea k'hamphani kapa moetsi?

A1: Re fektheri.

P2: Nako ea hau ea ho tlisa thepa e nka nako e kae?

A2: Ka kakaretso ke matsatsi a 5-10 haeba thepa e le teng. kapa ke matsatsi a 15-20 haeba thepa e se teng, ho latela

bongata.

P3: Na le fana ka disampole? Na ke mahala kapa ke tse ding?

A3: E, re ka fana ka sampole mahala empa ha re lefe litšenyehelo tsa thepa.

P4: Molemo oa k'hamphani ea hau ke ofe?

A4: Khamphani ea rona e na le sehlopha sa litsebi le mohala oa tlhahiso ea litsebi.

P5: Letšoao le 'mala li ka fetoloa?

A5: E, rea u amohela ho etsa sampole ea moetlo

P6: Na ho na le tshebeletso e nngwe e ntle eo khamphani ya hao e ka e fanang ka yona?

A6: E, re ka fana ka thekiso e ntle kamora ho rekisa le ho fana ka thepa kapele.