Liqubu tsa tšepe tse chesang tse phutholohileng tsa JIS Standard SY295 Type 2 U

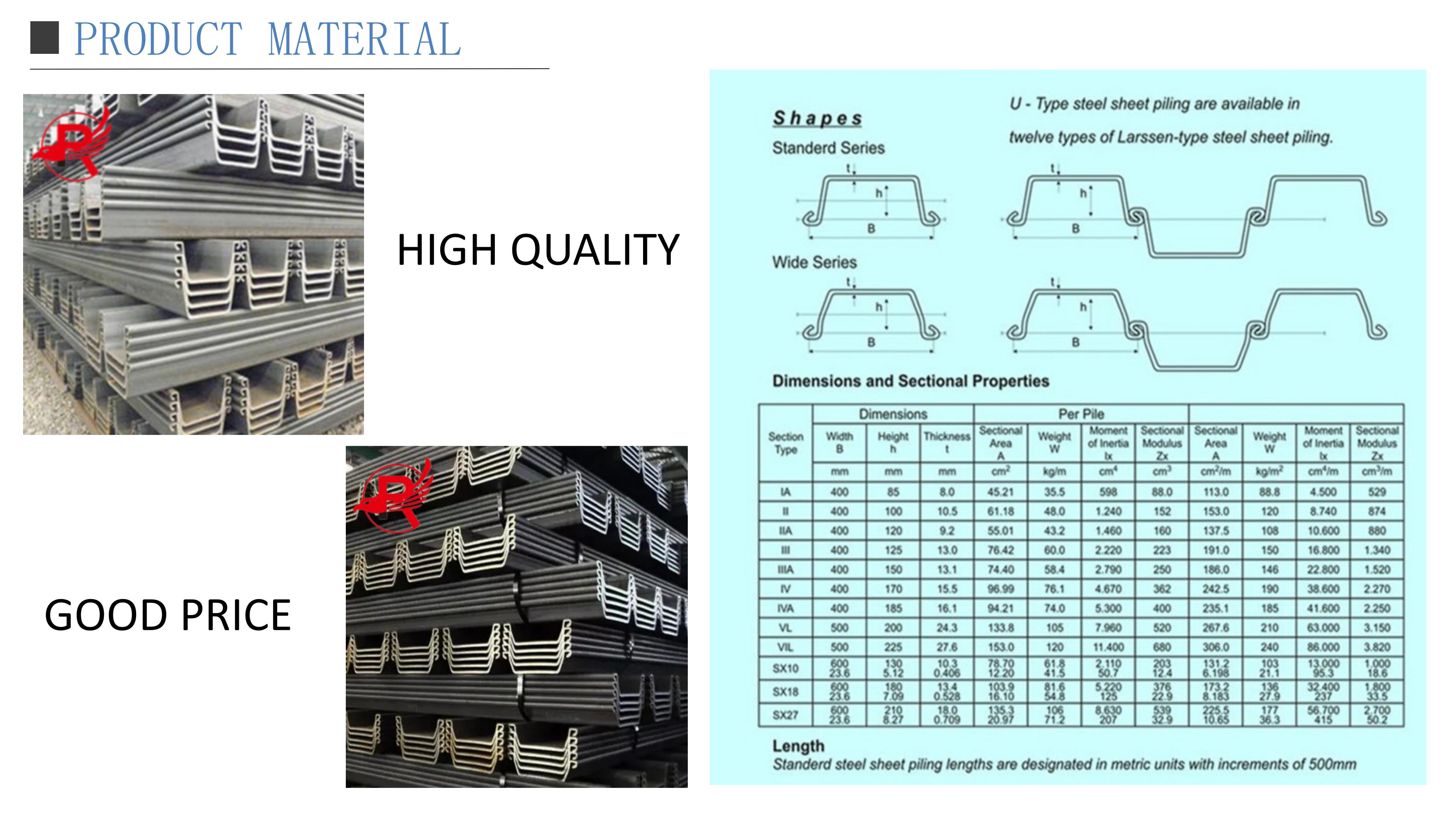

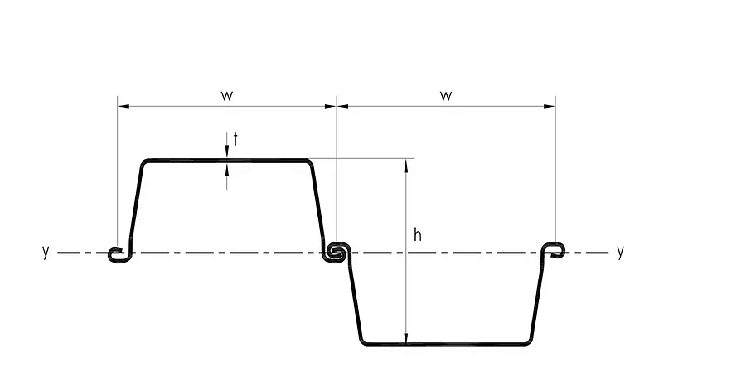

| Karolo | Bophara | Bolelele | Botenya | Sebaka se Tšeletseng | Boima ba 'mele | Modulus ea Karolo e Tenyetsehang | Motsotso oa Bofokoli | Sebaka sa ho Koahela (mahlakore ka bobeli ka qubu) | ||

|---|---|---|---|---|---|---|---|---|---|---|

| (w) | (h) | Sekoahelo (tf) | Web (tw) | Ka Phae | Ka Lebota | |||||

| mm | mm | mm | mm | cm2/m | kg/m | kg/m2 | cm3/m | cm4/m | m2/m | |

| Mofuta oa II | 400 | 200 | 10.5 | - | 152.9 | 48 | 120 | 874 | 8,740 | 1.33 |

| Mofuta oa III | 400 | 250 | 13 | - | 191.1 | 60 | 150 | 1,340 | 16,800 | 1.44 |

| Mofuta oa IIIA | 400 | 300 | 13.1 | - | 186 | 58.4 | 146 | 1,520 | 22,800 | 1.44 |

| Mofuta oa IV | 400 | 340 | 15.5 | - | 242 | 76.1 | 190 | 2,270 | 38,600 | 1.61 |

| Mofuta oa VL | 500 | 400 | 24.3 | - | 267.5 | 105 | 210 | 3,150 | 63,000 | 1.75 |

| Mofuta oa IIw | 600 | 260 | 10.3 | - | 131.2 | 61.8 | 103 | 1,000 | 13,000 | 1.77 |

| Mofuta oa IIIw | 600 | 360 | 13.4 | - | 173.2 | 81.6 | 136 | 1,800 | 32,400 | 1.9 |

| Mofuta oa IVw | 600 | 420 | 18 | - | 225.5 | 106 | 177 | 2,700 | 56,700 | 1.99 |

| Mofuta oa VIL | 500 | 450 | 27.6 | - | 305.7 | 120 | 240 | 3,820 | 86,000 | 1.82 |

*Romella imeile ho[email protected]ho fumana khotheishene bakeng sa merero ea hau

Sebaka sa Modulus ea Karolo

1100-5000cm3/m

Bophara ba Bophara (e le 'ngoe)

580-800mm

Botenya ba mefuta e fapaneng

5-16mm

Maemo a Tlhahiso

BS EN 10249 Karolo ea 1 le ea 2

Mekhahlelo ea Tšepe

SY295, SY390 le S355GP bakeng sa Mofuta oa II ho ea ho Mofuta oa VIL

S240GP, S275GP, S355GP & S390 bakeng sa VL506A ho isa ho VL606K

Bolelele

Bophahamo ba 27.0m

Bolelele bo Tloaelehileng ba Setoko sa 6m, 9m, 12m, 15m

Dikgetho tsa Thomello

Ba le bang kapa ba babeli

Lipara li hlephile, li phuthetsoe kapa li koaletsoe

Lesoba la ho Phahamisa

Ka setshelo (11.8m kapa ka tlase ho moo) kapa Break Bulk

Liaparo tsa Tšireletso ea Ts'enyeho

BOHOLO BA SEHLAHISOA

| LITLHAKISO TSA POTLOLO EA SHEET | |

| 1. Boholo | 1) 400*100 - 600*210MM |

| 2) Botenya ba lebota: 10.5-27.6MM | |

| 3) Qhobosheane ea pampiri ea mofuta oa U | |

| 2. Maemo a Tloaelehileng: | JIS A5523, JIS A5528 |

| 3. Thepa | SY295, SY390, S355 |

| 4. Sebaka sa fektheri ea rona | Shandong, China |

| 5. Tšebeliso: | 1) lebota le bolokang mobu |

| 2) kaho ea meaho | |

| 3) terata | |

| 6. Ho roala: | 1) E pentiloe ka botšo (seaparo sa varnish) 3) e galvanized |

| 7. Mokhoa: | hot rolled |

| 8. Mofuta: | Qhobosheane ea pampiri ea mofuta oa U |

| 9. Sebopeho sa Karolo: | U |

| 10. Tlhahlobo: | Tlhahlobo kapa tlhahlobo ea moreki ke motho oa boraro. |

| 11. Thomello: | Setshelo, Sejana se Sengata. |

| 12. Mabapi le Boleng ba Rona: | 1) Ha ho na tshenyo, ha ho na kobeha 2) Ha e na oli le matshwao 3) Thepa yohle e ka hlahlojwa ke motho wa boraro pele e romelwa |

LIKAROLOANA

Liqubu tsa tšepe tsa mofuta oa U ke mofuta oa thepa ea motheo e sebelisoang mererong ea kaho, haholo-holo libakeng tseo ho nang le tlhoko ea ho cheka ka botebo kapa ho boloka mobu le metsi. Tsena ke likarolo tsa bohlokoa tsa liqubu tsa tšepe tsa mofuta oa U:

1. Matla le ho Tšoarella: Liqubu tsa tšepe tsa mofuta oa ULi entsoe ka tšepe e matla haholo, e leng se li fang bokhoni bo botle ba ho jara moroalo le ho hanyetsa ho fetoha ha tsona. Sena se li etsa hore li lokele ho tšehetsa moroalo o boima le ho mamella maemo a thata a tikoloho.

2. Sistimi ea ho notlela: Qubu ea maqephe a 500 x 200 u e entsoe ka litsamaiso tsa ho notlela mathōkong a tsona, e leng se li lumellang ho kopanngoa habonolo ho etsa marako a tsoelang pele. Tšobotsi ena ea ho notlela e netefatsa botsitso 'me e thibela metsi kapa mobu ho kena ka har'a likheo.

3. Ho feto-fetoha ha maemo: Liqubu tsa tšepe tsa mofuta oa U li tla ka boholo le bolelele bo fapaneng, e leng se etsang hore li lokele lits'ebetso tse fapaneng. Li ka sebelisoa bakeng sa meaho ea nakoana le ea kamehla, joalo ka mabota a sireletsang, li-cofferdams, li-bulkheads le mabopo a noka.

4. Ho kenya habonolo:Qubu ea lakane ea 500 x 200 uli bonolo ho li kenya, li hloka mekhoa e bonolo ea ho khanna kapa ho tobetsa ka metsi. Sena se etsa hore li be le litšenyehelo tse tlase le ho boloka nako ha li bapisoa le likhetho tse ling tsa motheo.

5. E boloka litšenyehelo: Li-pile tsa tšepe tsa mofuta oa U li fana ka tharollo e bolokang litšenyehelo bakeng sa merero ea kaho ka lebaka la ho tšoarella ha tsona, bonolo ba ho li kenya, le bophelo bo bolelele. Li hloka tlhokomelo e fokolang 'me li ka sebelisoa hape kapa tsa sebelisoa hape kamora nako ea tsona ea tšebeletso.

6. E Sireletsa Tikoloho: Qubu ea maqephe a 500 x 200 u e sireletsa tikoloho kaha e ka sebelisoa hape, e leng se fokotsang tšusumetso mehloling ea tlhaho. E boetse e thusa ho thibela khoholeho ea mobu le ho boloka botsitso libakeng tse lebōpong la leoatle.

KOPO

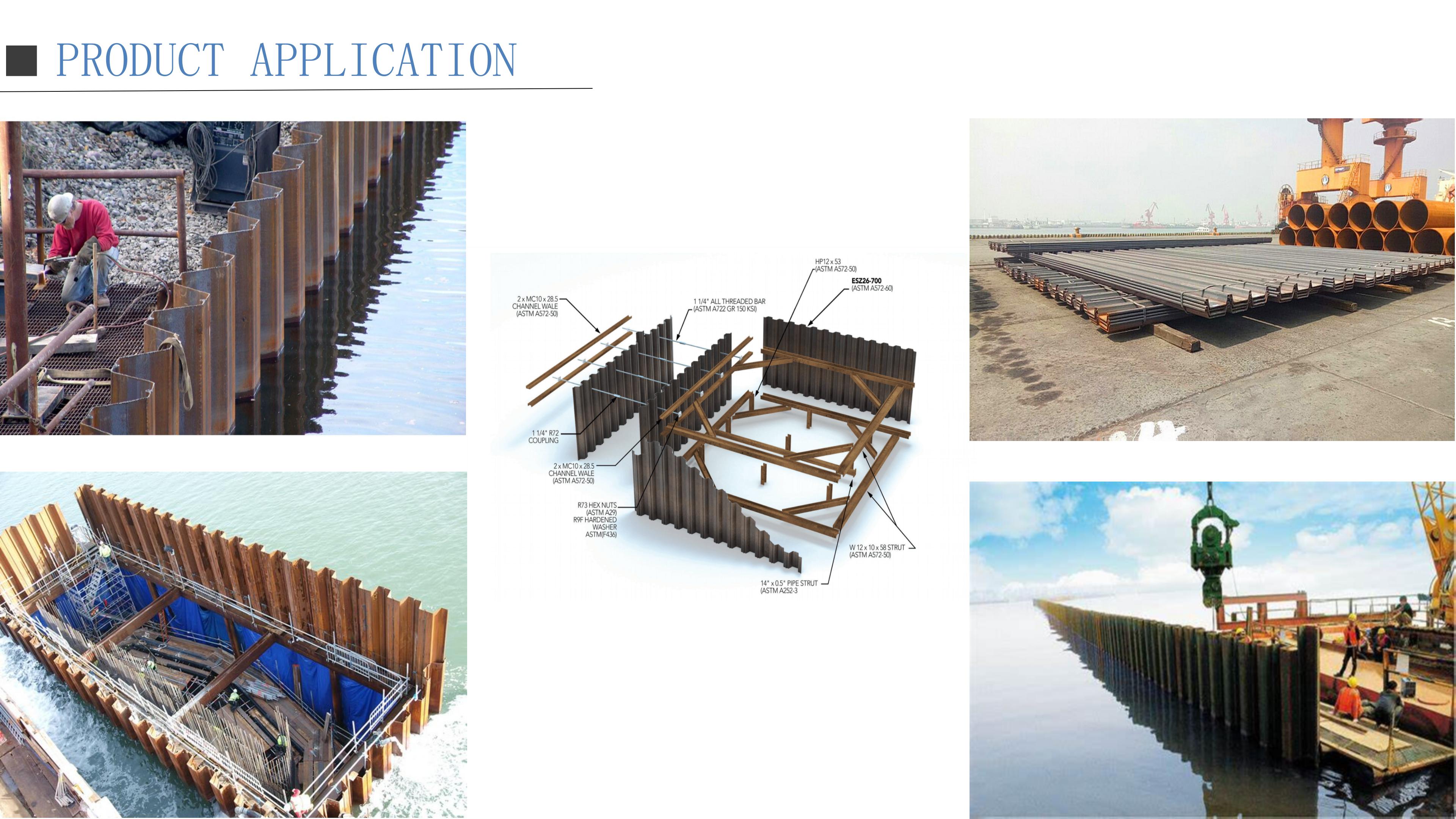

Liqubu tsa tšepe tse bōpehileng joaloka U li na le mefuta e mengata ea lits'ebetso liindastering tse fapaneng le mererong ea kaho. Tse ling tsa lits'ebetso tse tloaelehileng li kenyelletsa:

Mabota a ho sireletsa:qubu ea lakane ea tšepeLi sebelisoa haholo bakeng sa ho haha marako a ho sireletsa ho tšehetsa khatello ea mobu kapa metsi. Li fana ka botsitso le ho thibela khoholeho ea mobu, e leng se etsang hore li lokele merero ea meralo ea motheo joalo ka li-bustore tsa borokho, meaho ea ho paka makoloi ka tlas'a lefatše le nts'etsopele ea lebōpo la leoatle.

Li-Cofferdams le mabota a khaotsoeng: qubu ea tšepe e sebelisetsoa ho haha matloana a nakoana kapa a sa feleng metsing. A etsa tšitiso ea ho tlosa metsi sebakeng seo, e leng se lumellang mesebetsi ea kaho ho etsahala ntle le ho kenella ha metsi. A boetse a sebelisoa e le mabota a khaotsoeng ho thibela phallo ea metsi le ho laola maemo a metsi a ka tlas'a lefatše libakeng tsa kaho.

Mekhoa e tebileng ea motheo: Liqubu tsa tšepe tse bōpehileng joaloka U li sebelisoa e le karolo ea litsamaiso tse tebileng tsa motheo, joalo ka mabota a kopantsoeng le mabota a lerōle, ho tšehetsa lintho tse epolloang le ho tsitsisa mobu. Li ka sebetsa e le tharollo ea nakoana kapa ea ka ho sa feleng, ho latela litlhoko tsa projeke.

Tšireletso ea moroallo:lebota la qubu ea maselali sebelisetsoa ho thibela likhohola libakeng tse tlaase. Li ka kenngoa mabopong a linoka, mabōpong, kapa libakeng tse lebōpong la leoatle ho fana ka matla le khanyetso khahlanong le phallo ea metsi, ho sireletsa meralo ea motheo le thepa e potolohileng.

Meaho ea likepe: Liqubu tsa tšepe tse bōpehileng joaloka U li sebelisoa haholo kahong ea meaho e fapaneng ea leoatle, ho kenyeletsoa mabota a leoatle, litšitiso tsa metsi, li-jetties le liteishene tsa likepe. Li fana ka botsitso le ho sireletsa khahlanong le khoholeho e bakoang ke maqhubu le maqhubu libakeng tse lebopong la leoatle.

Meaho e ka tlas'a lefatše: qubu ea tšepe e sebelisetsoa ho tsitsisa lintho tse epolotsoeng bakeng sa meaho e ka tlas'a lefatše joalo ka likamore tse ka tlas'a lefatše, likarache tsa ho paka likoloi tse ka tlas'a lefatše le lithanele. Li fana ka tšehetso ea nakoana kapa ea kamehla ho thibela ho putlama ha mobu le ho netefatsa polokeho nakong ea kaho.

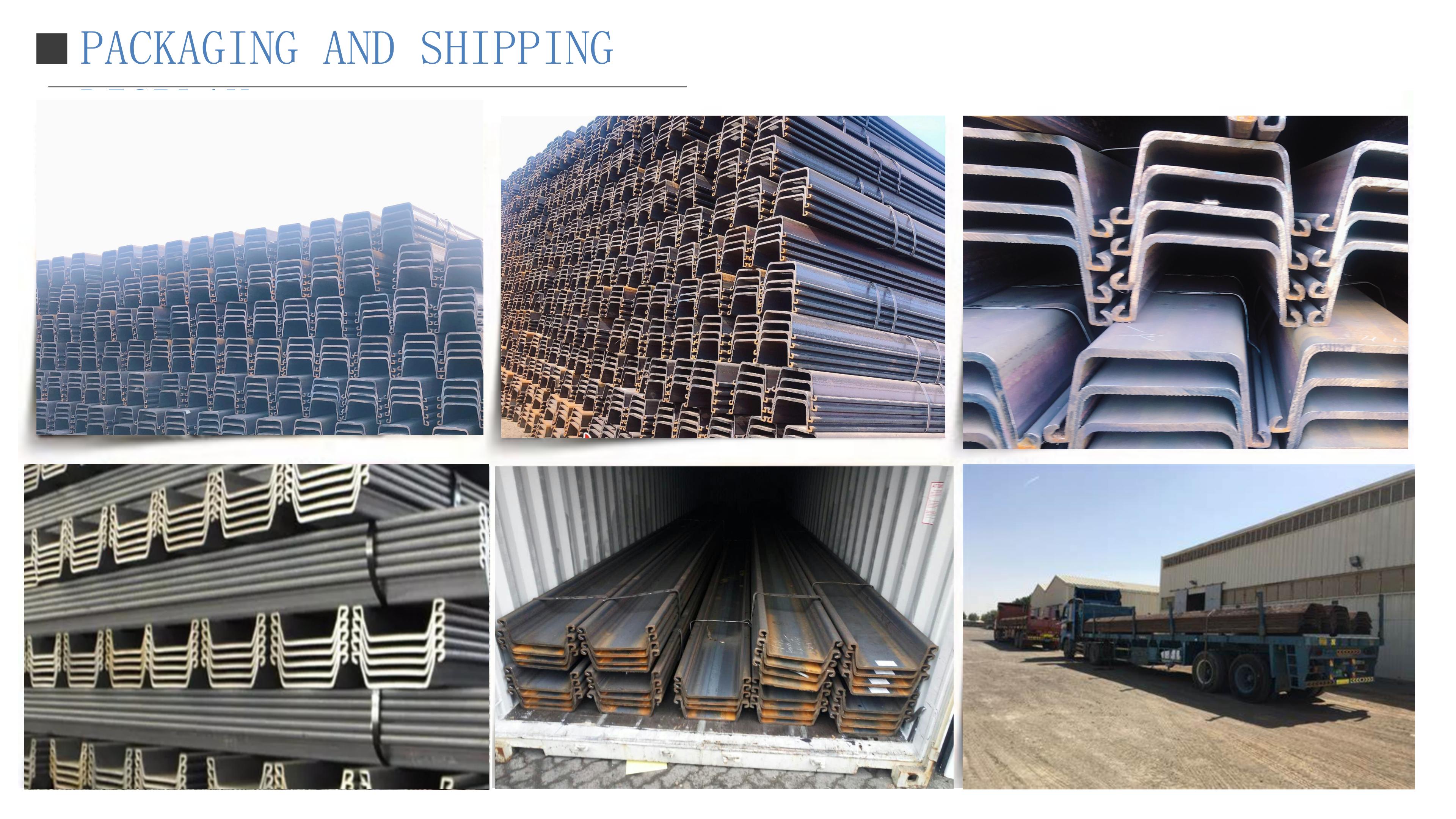

HO PHAKISA LE HO ROMELA

Ha ho tluoa tabeng ea ho paka le ho romella thepaqubu ea tšepe ea lakane,Ho bohlokoa ho netefatsa hore e tšoaroa hantle ebile e sirelelitsoe ho thibela tšenyo nakong ea lipalangoang. Mona ke litataiso tse ling tseo u lokelang ho li nahana:

Sephutheloana: Qubu e 'ngoe le e 'ngoe ea tšepe ea mofuta oa U e lokela ho pakoa ka bonngoe kapa ho kopanngoa hammoho ka mokhoa o sireletsehileng. Lisebelisoa tsa ho paka, tse kang liphalete tsa lehong, marapo, kapa lithapo tsa tšepe, li lokela ho ba matla ho lekana ho mamella boima le ho thibela motsamao ofe kapa ofe kapa ho falla nakong ea lipalangoang.

Tšireletso: Ho sireletsa liqubu tsa tšepe tsa mofuta oa U khahlanong le mafome kapa tšenyo, li lokela ho manehoa ka lera le sireletsang kapa ho pentoa pele li pakeloa. Ho feta moo, likoahelo tsa polasetiki kapa tse sa keneleng metsi li ka sebelisoa ho li sireletsa mongobo kapa maemong a leholimo a thata.

Ho sebetsana le: Nakong ea ho kenya le ho theola thepa, ho bohlokoa ho sebelisa lisebelisoa tse loketseng tsa ho phahamisa thepa le ho latela mekhoa e nepahetseng ea ho e sebetsana ho thibela ho kobeha, ho sotha, kapa mefuta e meng ea tšenyo. Ho molemo ho batla thuso ho litsebi tse nang le boiphihlelo kapa ho sheba litataiso tsa moetsi.

Lipalangoang:mofuta oa qubu ea pampirie lokela ho tsamaisoa ka likoloi tse loketseng, tse kang literaka tse bataletseng kapa lijana, ho latela bongata le moo e eang teng. Ts'ebetso ea lipalangoang e lokela ho netefatsa botsitso le ho thibela ho sisinyeha kapa motsamao ofe kapa ofe o ka lebisang tšenyo.

KETO EA BAREKI

Ha moreki a lakatsa ho etela sehlahisoa, hangata mehato e latelang e ka hlophisoa:

Etsa kopano ea ho etela: Bareki ba ka ikopanya le moetsi kapa moemeli oa thekiso esale pele ho etsa kopano ea nako le sebaka sa ho etela sehlahisoa.

Lokisetsa leeto le tataiswang: Hlophisa ditsebi kapa baemeli ba thekiso e le batataisi ba maeto ho bontsha bareki tshebetso ya tlhahiso, theknoloji le tsamaiso ya taolo ya boleng ba sehlahiswa.

Bontša lihlahisoa: Nakong ea ketelo, bontša lihlahisoa mekhahlelong e fapaneng ho bareki e le hore bareki ba ka utloisisa ts'ebetso ea tlhahiso le maemo a boleng ba lihlahisoa.

Araba lipotso: Nakong ea ketelo, bareki ba ka 'na ba e-ba le lipotso tse fapaneng, 'me motataisi oa bahahlauli kapa moemeli oa thekiso o lokela ho li araba ka mamello le ho fana ka tlhaiso-leseling e nepahetseng ea tekheniki le boleng.

Fana ka disampole: Haeba ho khoneha, disampole tsa dihlahiswa di ka fuwa bareki e le hore bareki ba ka utlwisisa boleng le dibopeho tsa sehlahiswa ka bohlale haholoanyane.

Tekolo: Kamora ketelo, latela kapele maikutlo a bareki mme o hloka ho fa bareki tšehetso le lits'ebeletso tse ling.

LBH

1. Nka fumana khotheishene joang ho tsoa ho uena?

O ka re siela molaetsa, 'me re tla araba molaetsa o mong le o mong ka nako.

2. Na o tla isa thepa ka nako?

E, re tšepisa ho fana ka lihlahisoa tsa boleng bo holimo le ho li tlisa ka nako. Botšepehi ke molao-motheo oa k'hamphani ea rona.

3.Na nka fumana disampole pele ke odara?

E, ehlile. Hangata disampole tsa rona ha di lefellwe, re ka di hlahisa ka disampole tsa hao kapa ka ditshwantsho tsa botekgeniki.

4. Lipehelo tsa hau tsa tefo ke life?

Nako ea rona ea tefo e tloaelehileng ke depositi ea 30%, 'me karolo e setseng khahlanong le B/L. EXW, FOB, CFR, CIF.

5. Na o amohela tlhahlobo ea motho oa boraro?

E, ruri rea amohela.

6. Re tšepa khamphani ea hau joang?

Re ikhethile khoebong ea tšepe ka lilemo tse ngata re le mofani oa khauta, ntlo-kholo e profinseng ea Tianjin, re amohelehile ho etsa lipatlisiso ka litsela life kapa life, ka mekhoa eohle.