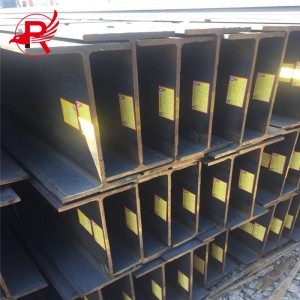

Boleng bo Holimo h16 x 101 150x150x7x10 Q235 Q345b Tšepe e Chesitsoeng e Chesitsoeng ea IPE HEA HEB EN H

Mokhoa oa Tlhahiso ea Sehlahisoa

Litlhaloso tsena li bontša mefuta e fapaneng eaMahlasedi a IPE a thehiloe holim'a 'onaka boholo le thepa ea tsona:

- HEALikarolo tsa tšepe (IPN): Tsena ke mabala a tšepe a bōpehileng joaloka I a nang le li-flange tse pharaletseng le marang-rang a teteaneng, a loketseng lits'ebetso tsa meaho tse hlokang bokhoni bo phahameng ba ho jara moroalo.

- HEBLikarolo tsa tšepe (IPB): Tsena ke mabala a tšepe a bōpehileng joaloka I a nang le bophara le botenya bo itekanetseng ba flange, a sebelisoang hangata mehahong e fapaneng ea meaho.

- Likarolo tsa tšepe tsa mofuta oa HEM: Tsena ke likarolo tsa tšepe tsa I-beam tse nang le bophahamo bo boholo ba flange le bophara bo bonyenyane ba flange, tse fellang ka matla a phahameng le bokhoni ba ho jara mojaro. Mefuta e fapaneng ea likarolo tsa tšepe tse tšekaletseng e na le litšobotsi tsa eona tsa moralo oa sebopeho; ka hona, mererong e itseng ea boenjiniere, mofuta o loketseng o lokela ho khethoa ho latela litlhoko tsa 'nete.

BOHOLO BA SEHLAHISOA

| Tlhophiso | Unt Boima ba 'mele kg/m) | Karolo e Tloaelehileng ho ikemela mm | Karolo Ama (cm² | |||||

| W | H | B | 1 | 2 | r | A | ||

| HE28 | AA | 61.3 | 264.0 | 280.0 | 7.0 | 10.0 | 24.0 | 78.02 |

| A | 76.4 | 270.0 | 280.0 | 80 | 13.0 | 24.0 | 97.26 | |

| B | 103 | 280.0 | 280.0 | 10.5 | 18.0 | 24.0 | 131.4 | |

| M | 189 | 310.0 | 288.0 | 18.5 | 33.0 | 24.0 | 240.2 | |

| HE300 | AA | 69.8 | 283.0 | 300.0 | 7.5 | 10.5 | 27.0 | 88.91 |

| A | 88.3 | 200.0 | 300.0 | 85 | 14.0 | 27.0 | 112.5 | |

| B | 117 | 300.0 | 300.0 | 11.0 | 19.0 | 27.0 | 149.1 | |

| M | 238 | 340.0 | 310.0 | 21.0 | 39.0 | 27.0 | 303.1 | |

| HE320 | AA | 74.3 | 301.0 | 300.0 | 80 | 11.0 | 27.0 | 94.58 |

| A | 97.7 | 310.0 | 300.0 | 9.0 | 15.5 | 27.0 | 124.4 | |

| B | 127 | 320.0 | 300.0 | 11.5 | 20.5 | 27.0 | 161.3 | |

| M | 245 | 359.0 | 309.0 | 21.0 | 40.0 | 27.0 | 312.0 | |

| HE340 | AA | 78.9 | 320.0 | 300.0 | 85 | 11.5 | 27.0 | 100.5 |

| A | 105 | 330.0 | 300.0 | 9.5 | 16.5 | 27.0 | 133.5 | |

| B | 134 | 340.0 | 300.0 | 12.0 | 21.5 | 27.0 | 170.9 | |

| M | 248 | 377.0 | 309.0 | 21.0 | 40.0 | 27.0 | 315.8 | |

| HE360 | AA | 83.7 | 339.0 | 300.0 | 9.0 | t2.0 | 27.0 | 106.6 |

| A | 112 | 350.0 | 300.0 | 10.0 | 17.5 | 27.0 | 142.8 | |

| B | 142 | 360.0 | 300.0 | 12.5 | 22.5 | 27.0 | 180.6 | |

| M | 250 | 395.0 | 308.0 | 21.0 | 40.0 | 27.0 | 318.8 | |

| HE400 | AA | 92.4 | 3780 | 300.0 | 9.5 | 13.0 | 27.0 | 117.7 |

| A | 125 | 390.0 | 300.0 | 11.0 | 19.0 | 27.0 | 159.0 | |

| B | 155 | 400.0 | 300.0 | 13.5 | 24.0 | 27.0 | 197.8 | |

| M | 256 | 4320 | 307.0 | 21.0 | 40.0 | 27.0 | 325.8 | |

| HE450 | AA | 99.8 | 425.0 | 300.0 | 10.0 | 13.5 | 27.0 | 127.1 |

| A | 140 | 440.0 | 300.0 | 11.5 | 21.0 | 27.0 | 178.0 | |

| B | 171 | 450.0 | 300.0 | 14.0 | 26.0 | 27.0 | 218.0 | |

| M | 263 | 4780 | 307.0 | 21.0 | 40.0 | 27.0 | 335.4 | |

| Tlhophiso | Yuniti Boima ba 'mele kg/m) | Karolo e Tloaelehileng Ho teba (mm) | Karolo Sebaka (cm²) | |||||

| W | H | B | 1 | 2 | r | A | ||

| HE50 | AA | 107 | 472.0 | 300.0 | 10.5 | 14.0 | 27.0 | 136.9 |

| A | 155 | 490.0 | 300.0 | t2.0 | 23.0 | 27.0 | 197.5 | |

| B | 187 | 500.0 | 300.0 | 14.5 | 28.0 | 27.0 | 238.6 | |

| M | 270 | 524.0 | 306.0 | 21.0 | 40.0 | 27.0 | 344.3 | |

| HE550 | AA | t20 | 522.0 | 300.0 | 11.5 | 15.0 | 27.0 | 152.8 |

| A | 166 | 540.0 | 300.0 | t2.5 | 24.0 | 27.0 | 211.8 | |

| B | 199 | 550.0 | 300.0 | 15.0 | 29.0 | 27.0 | 254.1 | |

| M | 278 | 572.0 | 306.0 | 21.0 | 40.0 | 27.0 | 354.4 | |

| HE60 | AA | t29 | 571.0 | 300.0 | t2.0 | 15.5 | 27.0 | 164.1 |

| A | 178 | 500.0 | 300.0 | 13.0 | 25.0 | 27.0 | 226.5 | |

| B | 212 | 600.0 | 300.0 | 15.5 | 30.0 | 27.0 | 270.0 | |

| M | 286 | 620.0 | 305.0 | 21.0 | 40.0 | 27.0 | 363.7 | |

| HE650 | AA | 138 | 620.0 | 300.0 | t2.5 | 16.0 | 27.0 | 175.8 |

| A | 190 | 640.0 | 300.0 | t3.5 | 26.0 | 27.0 | 241.6 | |

| B | 225 | 660.0 | 300.0 | 16.0 | 31.0 | 27.0 | 286.3 | |

| M | 293 | 668.0 | 305.0 | 21.0 | 40.0 | 27.0 | 373.7 | |

| HE700 | AA | 150 | 670.0 | 300.0 | 13.0 | 17.0 | 27.0 | 190.9 |

| A | 204 | 600.0 | 300.0 | 14.5 | 27.0 | 27.0 | 260.5 | |

| B | 241 | 700.0 | 300.0 | 17.0 | 32.0 | 27.0 | 306.4 | |

| M | 301 | 716.0 | 304.0 | 21.0 | 40.0 | 27.0 | 383.0 | |

| HE800 | AA | 172 | 770.0 | 300.0 | 14.0 | 18.0 | 30.0 | 218.5 |

| A | 224 | 790.0 | 300.0 | 15.0 | 28.0 | 30.0 | 285.8 | |

| B | 262 | 800.0 | 300.0 | 17.5 | 33.0 | 30.0 | 334.2 | |

| M | 317 | 814.0 | 303.0 | 21.0 | 40.0 | 30.0 | 404.3 | |

| HE800 | AA | 198 | 870.0 | 300.0 | 15.0 | 20.0 | 30.0 | 252.2 |

| A | 252 | 800.0 | 300.0 | 16.0 | 30.0 | 30.0 | 320.5 | |

| B | 291 | 900.0 | 300.0 | 18.5 | 35.0 | 30.0 | 371.3 | |

| M | 333 | 910.0 | 302.0 | 21.0 | 40.0 | 30.0 | 423.6 | |

| HEB1000 | AA | 222 | 970.0 | 300.0 | 16.0 | 21.0 | 30.0 | 282.2 |

| A | 272 | 0.0 | 300.0 | 16.5 | 31.0 | 30.0 | 346.8 | |

| B | 314 | 1000.0 | 300.0 | 19.0 | 36.0 | 30.0 | 400.0 | |

| M | 349 | 1008 | 302.0 | 21.0 | 40.0 | 30.0 | 444.2 | |

LIKAROLOANA

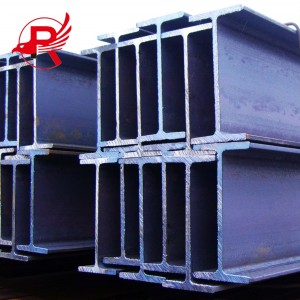

Likarolo tsa tšepe tsa HEA, HEB, le HEM ke mefuta ea libalaka tsa tšepe tsa IPE tse tloaelehileng tsa Europe (karolo e bōpehileng joaloka I) tse sebelisoang haholo kahong le boenjiniere ba meaho. Tsena ke litšobotsi tsa mantlha tsa mofuta o mong le o mong:

Karolo ea tšepe ea HEA (IPN):

Bophara le botenya ba flange e kholoanyane

E loketse meaho e nang le meroalo e boima

E fana ka bokgoni bo botle ba ho jara mojaro le matla a ho kobeha

Karolo ea tšepe ea HEB (IPB):

Bophara le botenya ba flange bo itekanetseng

E sebelisoa ka bongata, e atisa ho sebelisoa mehahong e fapaneng ea meaho

E kopanya matla le melemo e bobebe

Karolo ea tšepe ea HEM:

Bophahamo bo boholo ba flange le bophara bo bonyenyane

E fana ka matla a phahameng le bokgoni ba ho jara mojaro

E loketse meaho e nang le meroalo e boima le khatello e phahameng

ENHTšepe e bōpehileng joaloka eona

Sehlopha: EN10034:1997 EN10163-3:2004

Tlhaloso: HEA HEB le HEM

Tekanyetso: EN

TLHAHLOBO EA SEHLAHISOA

Litlhoko tsa bohlokoa tsa ho hlahloba tšepe e bōpehileng joaloka H li kenyelletsa lintlha tse latelang:

Boleng ba Ponahalo: Ponahalo ea tšepe e bōpehileng joaloka H e lokela ho fihlela maemo a amehang le litlhoko tsa bareki. Bokaholimo bo lokela ho ba bo boreleli le bo lekanang, bo se nang matheba a totobetseng, mengoapo, matheba a mafome le liphoso tse ling.

Litekanyo tsa Jiometri: Bolelele, bophara, bophahamo, botenya ba webo, le botenya ba flange ba tšepe e bōpehileng joaloka H li lokela ho latela maemo a amehang le litlhoko tsa bareki.

Ho otloloha: Ho otloloha ha tšepe e bōpehileng joaloka H ho lokela ho fihlela maemo a amehang le litlhoko tsa bareki. Sena se ka netefatsoa ka ho lekanya ho tšoana ha lipheletso tse peli kapa ho sebelisa tekanyo ea ho otloloha.

Torsion: Torsion ea tšepe e bōpehileng joaloka H e lokela ho finyella maemo a amehang le litlhoko tsa bareki. Sena se ka netefatsoa ka ho lekanya ho otloloha ha mahlakore kapa ho sebelisa teko ea torsion.

Ho kheloha ha boima: Boima ba tšepe e bōpehileng joaloka H bo lokela ho finyella maemo a amehang le litlhoko tsa bareki. Ho kheloha ha boima ho ka hlahlojoa ka ho bekha.

Sebopeho sa Lik'hemik'hale: Haeba tšepe e bōpehileng joaloka H e hloka ho tjheseletsa kapa ho sebetsa ka tsela e 'ngoe, sebopeho sa eona sa lik'hemik'hale se lokela ho fihlela maemo a loketseng le litlhoko tsa bareki.

Matlotlo a Mekaniki: Matlotlo a mekaniki a tšepe e bōpehileng joaloka H a lokela ho fihlela maemo a amehang le litlhoko tsa bareki, ho kenyeletsoa matla a ho thaepa, matla a ho ikatisa, ho lelefala, jj.

Teko e sa Senyeheng: Haeba ho hlokahala teko e sa senyeheng bakeng sa tšepe e bōpehileng joaloka H, e lokela ho etsoa ho latela maemo a amehang le litlhoko tsa bareki ho netefatsa hore boleng ba eona ba kahare bo fihlela litlhaloso.

Ho paka le ho ngola mabitso: Ho paka le ho ngola mabitso a tšepe e bōpehileng joaloka H ho lokela ho latela maemo a amehang le litlhoko tsa bareki, ho nolofatsa ho tsamaisoa le ho bolokoa.

Ka bokhutšoanyane, ha ho hlahlojoa tšepe e bōpehileng joaloka H, litlhoko tsohle tse boletsoeng ka holimo li lokela ho nahanoa ka botlalo ho netefatsa hore boleng bo fihlela maemo a amehang le litlhoko tsa bareki, kahoo ho fa basebelisi lihlahisoa tsa tšepe tse bōpehileng joaloka H tsa boleng bo holimo.

KOPO

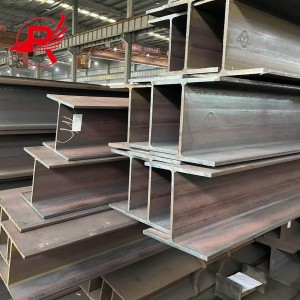

Mahlaseli a HEA, HEB, le HEMli na le mefuta e mengata ea lits'ebetso indastering ea kaho le boenjiniere ba meaho. Tse ling tsa ts'ebeliso e tloaelehileng li kenyelletsa:

- Merero ea Kaho: Likarolo tsena tsa tšepe li sebelisoa hangata kahong ea meaho ea khoebo le ea indasteri, li fana ka tšehetso bakeng sa fatše, marulelo le meaho e meng e jarang mojaro.

Boenjiniere ba Borokho: Li sebelisoa kahong ea borokho, li tšehetsa borokho ba borokho le likarolo tse ling tsa sebopeho.

Meaho ea Liindasteri: Likarolo tsa tšepe tsa HEA, HEB, le HEM li sebelisoa haholo kahong ea mehaho ea liindasteri joalo ka matlo a polokelo, lifeme le libaka tsa polokelo.

Diforeimi tsa Meaho: Di ka sebediswa ho aha diforeimi tsa meaho e meholo le merero ya meralo ya motheo, ho fana ka tshehetso bakeng sa mabota, mahlakore a ka pele le dikarolo tse ding tsa meaho.

Tšehetso ea Lisebelisoa: Likarolo tsena tsa tšepe li ka sebelisoa ho tšehetsa mechine le lisebelisoa tse boima libakeng tse fapaneng tsa indasteri.

Merero ea Meralo ea Motheo: Likarolo tsa tšepe tsa HEA, HEB, le HEM le tsona li sebelisoa kahong ea merero ea meralo ea motheo e kang lithanele, boema-fofane le lifeme tsa motlakase.

Ka bokhutšoanyane, likarolo tsena tsa tšepe li bapala karolo ea bohlokoa mererong e fapaneng ea kaho le boenjiniere, li fana ka tšehetso e matla le e tšepahalang ea meaho. Ho tenyetseha ha tsona, matla le bokhoni ba ho jara mojaro li li etsa hore e be thepa ea bohlokoa ka ho fetisisa meahong ea sejoale-joale le moralo oa meralo ea motheo.

HO PHAKISA LE HO ROMELA

Sephutheloana le Tšireletso

Ho paka hantle ho bohlokoa bakeng sa ho netefatsa boleng ba tšepe e bōpehileng joaloka ASTM A36 H nakong ea lipalangoang le polokelo: Sebelisa marapo/lithapo tsa tšepe tse matla haholo ho kopanya maballo a tšepe ka mokhoa o sireletsehileng ho thibela ho sisinyeha le ho senyeha; Sebelisa thepa e hanelang boemo ba leholimo joalo ka polasetiki kapa li-tarpaulin tse sa keneleng metsi ho sireletsa khahlanong le mongobo le lerōle, ho thibela mafome.

Ho kenya, ho jarolla le ho sireletsa

Tšoara libalaka tsa tšepe tse pakiloeng ka hloko nakong ea ho kenya le ho theola thepa: Sebelisa lisebelisoa tse loketseng tsa ho phahamisa tse kang liforoko kapa likerene ho netefatsa polokeho le katleho; Ha u kenya thepa, aba libalaka tsa tšepe ka ho lekana 'me u li lokise hantle ho thibela tšenyo ea sebopeho; Kamora ho kenya thepa, tiisa thepa ka lithapo, liketane, jj., ho netefatsa botsitso le ho thibela ho falla nakong ea lipalangoang. Kakaretso ena e khutšoanyane e shebana le mekhoa le litlhoko tsa bohlokoa, e leng se etsang hore ho be bonolo ho utloisisa tlhahisoleseling ea bohlokoa kapele. Haeba u lakatsa ho nolofatsa karolo efe kapa efe kapa ho eketsa lintlha tse itseng (joalo ka mefuta ea thepa e sireletsang), ka kopo re tsebise.

LBH

1. Nka fumana khotheishene joang ho tsoa ho uena?

O ka re siela molaetsa, 'me re tla araba molaetsa o mong le o mong ka nako.

2. Na o tla isa thepa ka nako?

E, re tšepisa ho fana ka lihlahisoa tsa boleng bo holimo le ho li tlisa ka nako. Botšepehi ke molao-motheo oa k'hamphani ea rona.

3.Na nka fumana disampole pele ke odara?

E, ehlile. Hangata disampole tsa rona ha di lefellwe, re ka di hlahisa ka disampole tsa hao kapa ka ditshwantsho tsa botekgeniki.

4. Lipehelo tsa hau tsa tefo ke life?

Nako ea rona ea tefo e tloaelehileng ke depositi ea 30%, 'me karolo e setseng khahlanong le B/L. EXW, FOB, CFR, CIF.

5. Na o amohela tlhahlobo ea motho oa boraro?

E, ruri rea amohela.

6. Re tšepa khamphani ea hau joang?

Re ikhethile khoebong ea tšepe ka lilemo tse ngata re le mofani oa khauta, ntlo-kholo e profinseng ea Tianjin, re amohelehile ho etsa lipatlisiso ka litsela life kapa life, ka mekhoa eohle.