Mofani oa Chaena ea Extruded Hexagonal Aluminium Rod Long Hexagon Bar 12mm 2016 astm 233

Qaqiso ea Sehlahisoa

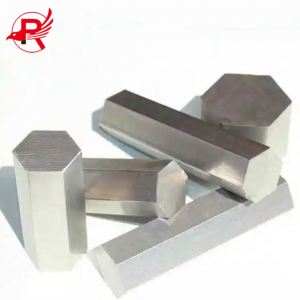

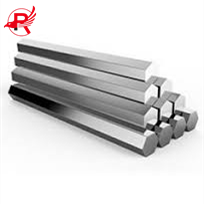

Thupa ea aluminium e nang le mahlakore a tšeletseng ke sehlahisoa sa aluminium se bōpehileng joaloka prism se nang le mahlakore a tšeletseng, e leng thepa e sebelisoang haholo indastering.

Thupa ea aluminium e nang le mahlakore a tšeletseng e na le litšobotsi tsa boima bo bobebe, ho tiea hantle, matla a phahameng le ho tsamaisa motlakase hantle, 'me e sebelisoa haholo e le ho qhala mocheso le likarolo tsa sebopeho lisebelisoa tsa elektroniki le tsa motlakase.

Ka lebaka la litšobotsi tsa sebopeho sa mahlakore a tšeletseng, e loketse haholo ho etsa likarolo le libopeho tse fapaneng.

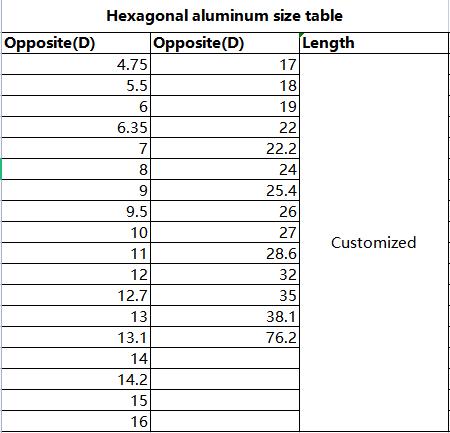

Litlhaloso

Indastering ea tlhahiso ea mechini, e sebelisoa haholo ho etsa mefuta e fapaneng ea li-stamping dies; ts'ebetsong ea lisebelisoa tsa hardware, e sebelisoa ho etsa lisebelisoa tse fapaneng tsa tšepe, liphaephe le likarolo tse fapaneng tse nang le sebopeho se ikhethang; indastering ea likoloi, e ka sebelisoa bakeng sa litsamaiso tsa ho pholisa tse kang li-block tsa enjene le meropa ea brake le poleiti ea khohlano e ho eona; ho feta moo, e ka boela ea sebelisoa e le thepa ea kalafo ea ho thibela ho bola bakeng sa lisebelisoa tsa lik'hemik'hale, jj.

Kopo

1. E loketse lihlahisoa tsa elektroniki le tsa motlakase e le likarolo tsa ho qhala mocheso kapa likarolo tsa sebopeho, joalo ka li-radiator, li-evaporator, li-condenser le lisebelisoa tse ling tsa ho qhala mocheso.

2. E sebediswa tsamaisong ya ho phodisa ya enjene indastering ya dikoloi le poleiting ya kgohlano hodima moropa wa brake; e ka boela ya sebediswa e le thepa ya kalafo ya ho thibela tshenyo disebedisweng tsa indasteri ya dikhemikhale.

3. E ka nkela likarolo tsa koporo sebaka e le solder nakong ea ho tjheseletsa, tse kang: hlooho ea tšepe ea ho solder ea motlakase, nozzle ea sethunya sa moea o chesang, terata ea solder, bolo ea solder jj.

4. E ka boela ea sebelisoa ho e-na le ho tima medium bakeng sa likarolo tsa tšepe.

Lisebelisoa tsa aluminium. Tse latelang li sebelisa haholo-holo motsoako oa aluminium oa 6061 e le mohlala ho hlahisa:

Motsoako oa Aluminium oa 6061

Motsoako oa aluminium oa 6061 ke motsoako o phekoloang mochesong o nang le sebopeho se setle, ho tjheseletsa, ho sebetsa ka thata, le matla a mahareng, 'me o ntse o ka boloka ts'ebetso e ntle kamora ho hokelloa.

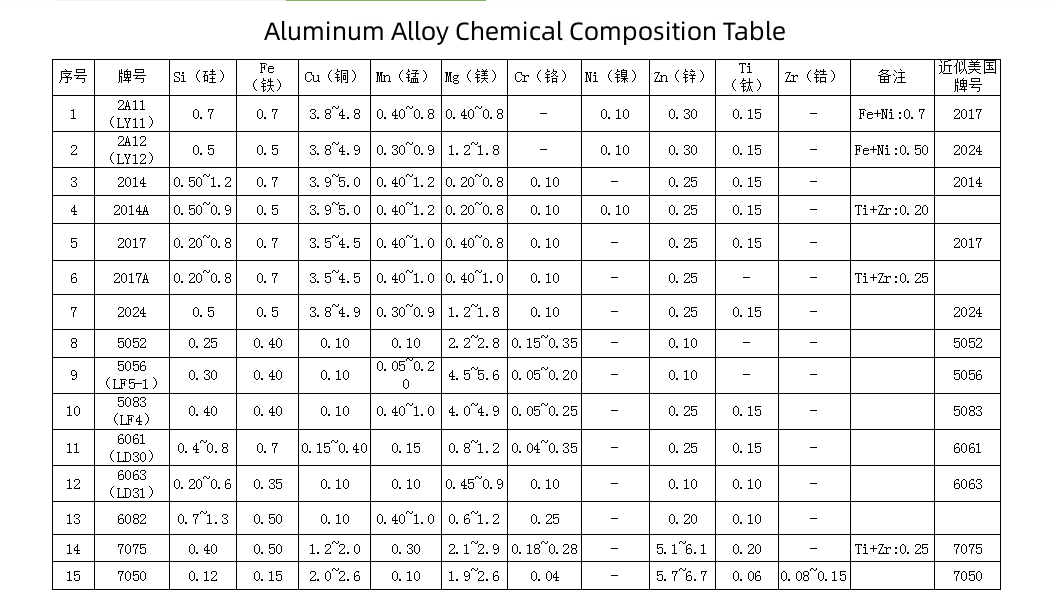

Sebopeho sa lik'hemik'hale sa motsoako oa aluminium oa 6061 (%):

Cu: 0.15~0.4 Mn:0.15 Mg:0.8~1.2Zn: 0.25 Cr: 0.04~0.35 Ti: 0.15 Si:0.4~0.8 Fe: 0.7 Al: ho leka-lekana

Tšebeliso e ka sehloohong: E sebelisoa haholo likarolong tse fapaneng tsa meaho ea indasteri tse hlokang matla a itseng le ho hanyetsa ho hoholo ha mafome, joalo ka literaka tsa tlhahiso, mehaho ea litora, likepe, literene le likoloi tsa terene. 6061 Thepa ea motsoako oa aluminium:

Matla a ho thaepa a alloy ea aluminium ea 6061 ke 124MPa, matla a ho thaepa ke 5.2MPa, sekhahla sa ho lelefala ke 25.0%, modulus ea ho tenyetseha ke 68.9 GPa, 'me matla a ho qetela a ho kobeha ke 28MPa.

6061 e sebediswa hangata dibakeng tsa difofane, diteraka, meaho ya ditora, diphaephe, dikepe, difofane, difofane, tshireletso le ditshebediso tse ding tsa meralo tse hlokang matla, ho tjheseletsa le ho hanyetsa mafome.

Motsoako oa aluminium oa 6061 o na le melemo e latelang: 1. Motsoako o matla o ka phekoloang ke mocheso. 2. Thepa e ntle ea mechini. 3. Tšebeliso e ntle. 4. Ho bonolo ho e sebetsana, ho hanyetsa ho tsofala hantle. 5. Ho hanyetsa ho ts'oha hantle le ho hanyetsa oxidation.

Motsoako oa aluminium oa 6061 o sebelisoa hangata lisebelisoa tsa lifofane, literaka, mehaho ea litora, liphaephe, likepe, lifofane, lifofane, tšireletso le lits'ebetso tse ling tsa meralo tse hlokang matla, ho tjheseletsa le ho hanyetsa mafome. Tse kang: likarolo tsa lifofane, li-gear le li-shaft, likarolo tsa fuse, li-shaft tsa lisebelisoa le li-gear, likarolo tsa polokeho tsa li-jump valve, li-turbine, linotlolo, jj.

Ke motsoako oa A-Mg-Si o nang le matla a mahareng, polasetiki e ntle le ho hanyetsa mafome hantle. Haholo-holo, ha ho na tšekamelo ea ho petsoha ha mafome a khatello, ho tjheseletsa ha eona ho hotle, ho hanyetsa mafome le ho sebetsa ha serame li ntle, ke mofuta oa tšebeliso e pharaletseng. Motsoako o tšepisang haholo. E ka fetoloa hore e be anodized le ho penta, 'me e ka boela ea penta ka enamel, e loketseng thepa ea mokhabiso oa moaho. E na le Cu e nyane, kahoo matla a eona a phahame ho feta a 6063, empa e bonolo ho e tima.

3, Litšobotsi le Mekhoa ea Ntlafatso ea Likarolo tsa Terene:

Hape e phahame ho feta 6063. Ho tima moea ho ke ke ha finyelloa ka mor'a ho ntša moea, 'me ho hloka ho rarolloa bocha le ho tima moea ho fumana matla a holimo.

Dikarolo tse ka sehloohong tsa ho kopanya tsa kgauta ya 6061 Taiwan ke magnesium le silicon, mme di bopa karolo ya Mg2Si. Haeba e na le tekanyo e itseng ya manganese le chromium, e ka fokotsa phello e mpe ya tshepe; ka dinako tse ding ho eketswa koporo e nyane kapa zinki ho ntlafatsa thatafalo ya motswako.

Matla ntle le ho fokotsa haholo ho hanyetsa ha yona mafome; ho na le koporo e nyane ka hara thepa e tsamaisang motlakase ho fokotsa ditlamorao tse mpe tsa titanium le tshepe hodima motlakase; aluminium kapa titanium di ka ntlafatsa dithollo le ho laola sebopeho sa ho kgutlisa dintho hape;

E le ho ntlafatsa bokgoni ba ho sebetsa, loto le bismuth di ka eketswa. Tharollo e tiileng ya Mg2Si ka aluminium e etsa hore motswako o be le mosebetsi wa ho thatafatsa botsofadi ba maiketsetso.

6061-T651 ke motsoako o ka sehloohong oa motsoako oa 6061. Ke sehlahisoa sa motsoako oa aluminium sa boleng bo holimo se hlahisoang ka kalafo ea mocheso le ts'ebetso ea ho otlolla pele. Leha matla a eona a ke ke a bapisoa le letoto la 2XXX kapa letoto la 7XXX, metsoako ea eona ea magnesium le silicon e ikhetha.

E na le thepa e mengata, ts'ebetso e ntle ea ts'ebetso, litšobotsi tse ntle tsa ho tjheseletsa le thepa ea electroplating, ho hanyetsa mafome hantle, ho ba thata haholo le ho se fetohe ha e sebelisitsoe, thepa e teteaneng e se nang liphoso ebile e bonolo ho e bentša, e bonolo ho e sebelisa filiming ea 'mala, phello e ntle ea oxidation le likarolo tse ling tse ntle.

4, Chate ea phallo ea tlhahiso ea terene:

Ho qhibilihisa → ho lahla → ho saga dithupa → ho kopanya dithupa tsa aluminium → ho phodisa, ho hlatswa dithupa → dithupa tsa aluminium ka tlung ya polokelo.

LBH

1. Nka fumana khotheishene joang ho tsoa ho uena?

O ka re siela molaetsa, 'me re tla araba molaetsa o mong le o mong ka nako.

2. Na o tla isa thepa ka nako?

E, re tšepisa ho fana ka lihlahisoa tsa boleng bo holimo le ho li tlisa ka nako. Botšepehi ke molao-motheo oa k'hamphani ea rona.

3.Na nka fumana disampole pele ke odara?

E, ehlile. Hangata disampole tsa rona ha di lefellwe, re ka di hlahisa ka disampole tsa hao kapa ka ditshwantsho tsa botekgeniki.

4. Lipehelo tsa hau tsa tefo ke life?

Nako ea rona ea tefo e tloaelehileng ke depositi ea 30%, 'me karolo e setseng khahlanong le B/L. EXW, FOB, CFR, CIF.

5. Na o amohela tlhahlobo ea motho oa boraro?

E, ruri rea amohela.

6. Re tšepa khamphani ea hau joang?

Re ikhethile khoebong ea tšepe ka lilemo tse ngata re le mofani oa khauta, ntlo-kholo e profinseng ea Tianjin, re amohelehile ho etsa lipatlisiso ka litsela life kapa life, ka mekhoa eohle.