Phepelo ea Fektheri Sy295 Sy390 S355gp Cold Rolled U Type Steel Sheet

Mokhoa oa Tlhahiso ea Sehlahisoa

Ts'ebetso ea tlhahiso eathaepa qubu ea pampiri ea uhangata e kenyelletsa mehato e latelang:

Tokiso ea thepa e tala: Lokisetsa thepa e tala bakeng saqubu ea lakane ea u, hangata lipoleiti tsa tšepe tse phuthoang ka mocheso kapa lipoleiti tsa tšepe tse phuthoang ka serame.

Ho phutholla poleiti: Poleiti e tala ea tšepe e fepeloa ka har'a mochini o phuthollang poleiti bakeng sa ts'ebetso ea ho phutholla poleiti ho e bopa hore e be karolo e tšekaletseng e bōpehileng joaloka U.

Ho kobeha ka serame: Poleiti ea tšepe e phutholohileng e kobehile ka serame, 'me poleiti ea tšepe e etsoa ke mochini o kobehang ka serame kapa mochini o kobehang ho e etsa karolo e tšekaletseng e bōpehileng joaloka U.

Ho seha: Sebelisa lisebelisoa tsa ho seha ho seha liqubu tsa maqephe ka boholo bo loketseng ho latela bolelele bo hlokahalang.

Ho tjheseletsa (haeba ho hlokahala): Etsa ts'ebetso e hlokahalang ea ho tjheseletsa holim'a lintho tse batangmabota a qubu ea tšepe ho eaetsa bonnete ba hore khokahano e tiile mme e fihlela maemo a amehang.

Kalafo ea bokaholimo: Kalafo ea bokaholimo e etsoa holim'a sehlahisoa se felileng, joalo ka ho tlosa mafome, ho penta, jj., ho ntlafatsa ts'ebetso ea sehlahisoa khahlanong le mafome.

Tlhahlobo le Taolo ea Boleng: Tlhahlobo ea lihlahisoa tse felileng ho netefatsa hore li fihlela litlhoko tsa maemo le litlhaloso tse amehang.

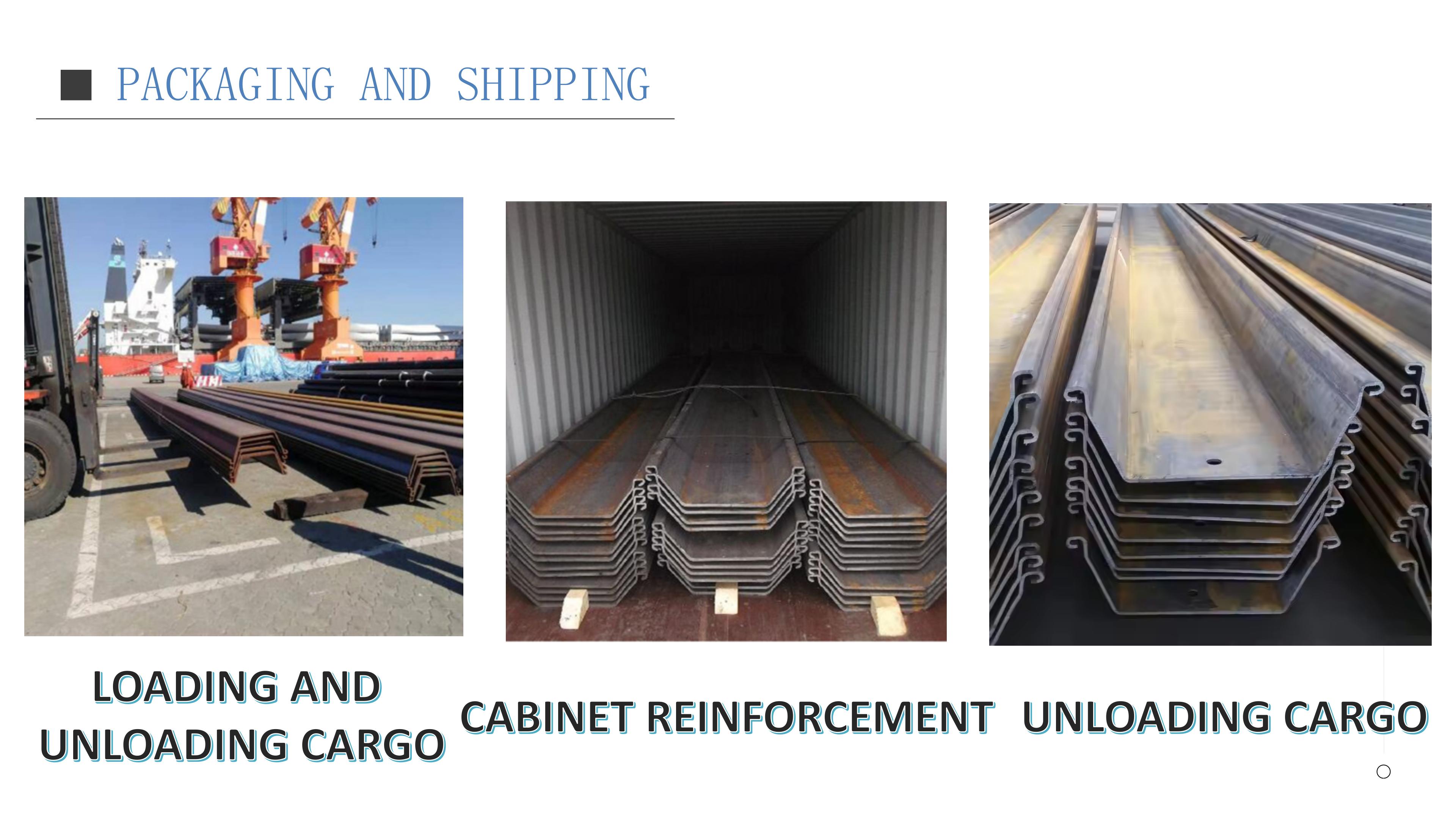

Sephutheloana le Thomello: Sehlahisoa se felileng sea pakoa 'me se lokisetsoa ho isoa ho moreki kapa sebakeng sa kaho.

Mehato ena e ka fapana ho latela mokhoa oa tlhahiso le lisebelisoa, empa ka kakaretso ke ea bohlokoa bakeng sa ts'ebetso ea tlhahiso ea liqubu tsa tšepe tse bōpehileng joaloka U tse batang.

| Lebitso la Sehlahisoa | |

| Kereiti ea Tšepe | S275,S355,S390,S430,SY295,SY390,ASTM A690 |

| Tekanyetso ea tlhahiso | EN10248,EN10249,JIS5528,JIS5523,ASTM |

| Nako ea thomello | Beke e le 'ngoe, lithane tse 80000 li teng |

| Lisetifikeiti | ISO9001, ISO14001, ISO18001, CE FPC |

| Litekanyo | Litekanyo life kapa life, bophara bofe kapa bofe x bophahamo x botenya |

| Bolelele | Bolelele bo le bong ho fihlela ho feta 80m |

1. Re ka hlahisa mefuta eohle ea liqubu tsa masela, liqubu tsa liphaephe le lisebelisoa, re ka fetola mechini ea rona ho e hlahisa ka bophara bofe kapa bofe x bophahamo x botenya.

2. Re ka hlahisa bolelele bo le bong ho fihlela ho 100m, 'me re ka etsa mesebetsi eohle ea ho penta, ho seha, ho tjheseletsa jj fekthering.

3. E netefalitsoe ka botlalo machabeng: ISO9001, ISO14001, ISO18001, CE, SGS, BV jj.

*Romella imeile ho[email protected]ho fumana khotheishene bakeng sa merero ea hau

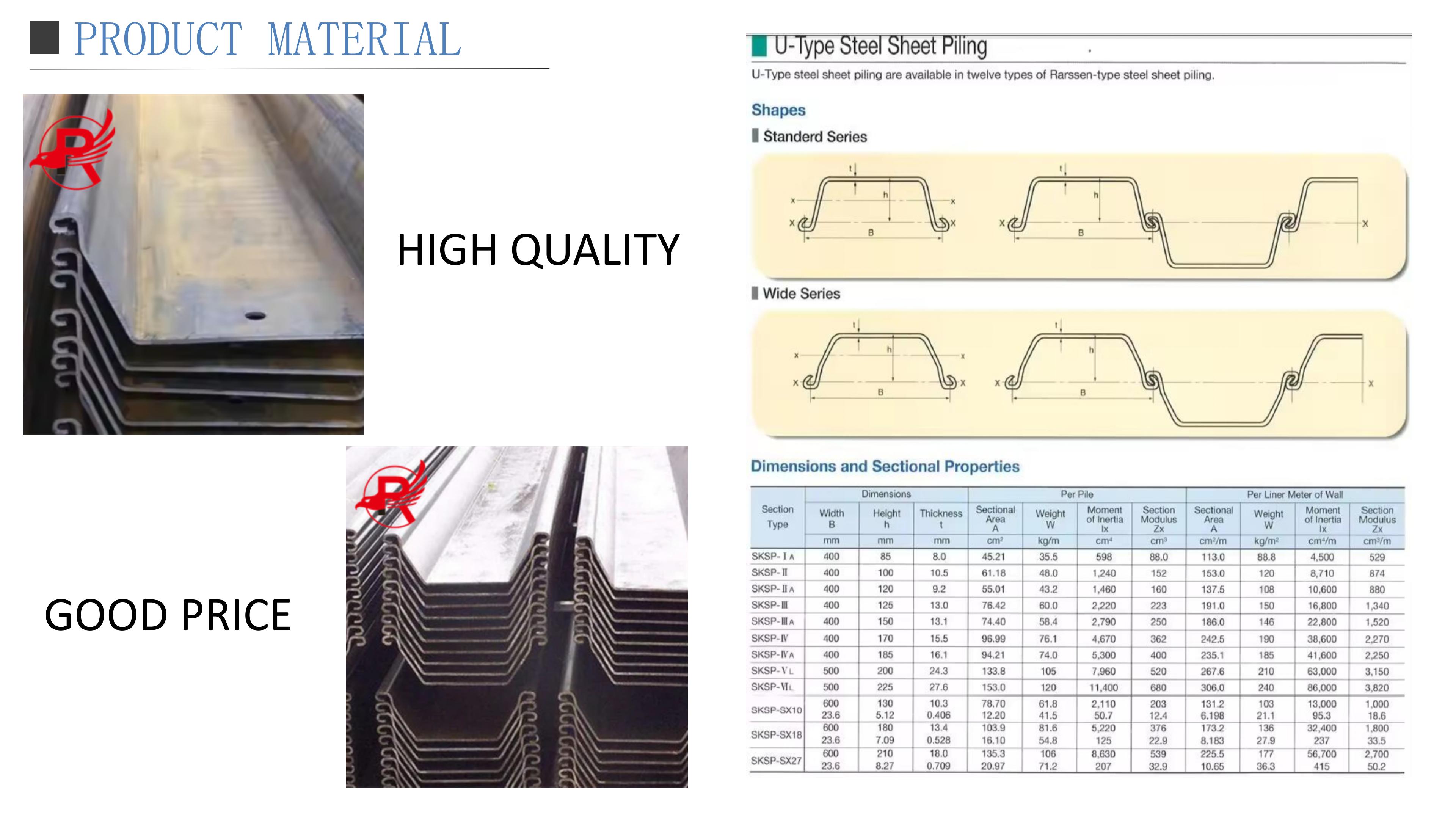

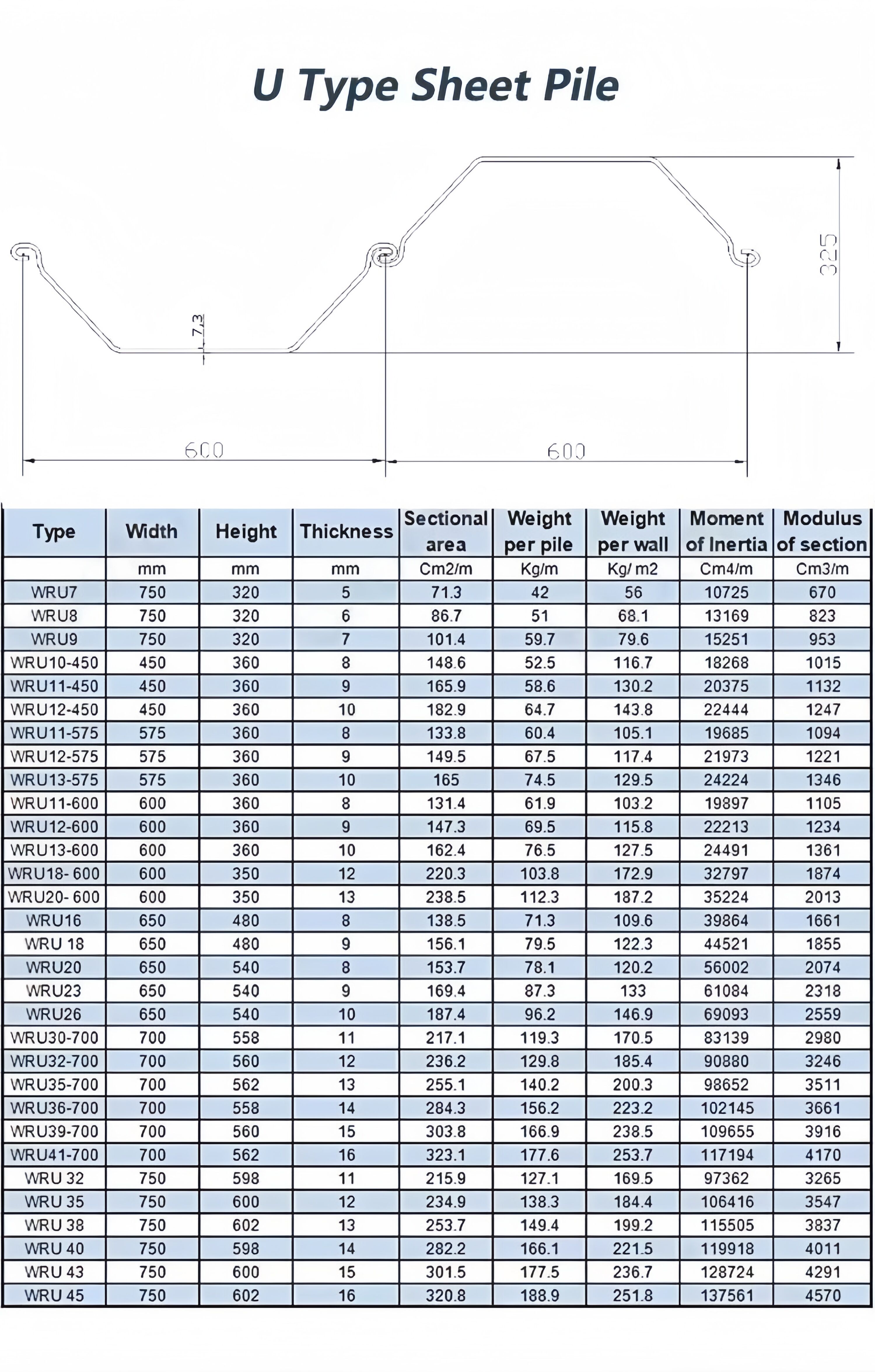

Sebaka sa Modulus ea Karolo

1100-5000cm3/m

Bophara ba Bophara (e le 'ngoe)

580-800mm

Botenya ba mefuta e fapaneng

5-16mm

Maemo a Tlhahiso

BS EN 10249 Karolo ea 1 le ea 2

Mekhahlelo ea Tšepe

SY295, SY390 le S355GP bakeng sa Mofuta oa II ho ea ho Mofuta oa VIL

S240GP, S275GP, S355GP & S390 bakeng sa VL506A ho isa ho VL606K

Bolelele

Bophahamo ba 27.0m

Bolelele bo Tloaelehileng ba Setoko sa 6m, 9m, 12m, 15m

Dikgetho tsa Thomello

Ba le bang kapa ba babeli

Lipara li hlephile, li phuthetsoe kapa li koaletsoe

Lesoba la ho Phahamisa

Ka setshelo (11.8m kapa ka tlase ho moo) kapa Break Bulk

Liaparo tsa Tšireletso ea Ts'enyeho

LIKAROLOANA

Qubu ea Lipampiri tsa TšepeLilemong tsa bo-1950, kaho ea pele ea borokho ba terene ea cofferdam naheng ea heso e ile ea hlahisoa 'me ea sebelisoa ke Ofisi ea Borokho ea Lefapha la Literene ho tsoa Soviet Union ea mehleng. Ka nts'etsopele e potlakileng ea moruo oa naha ea heso, mabota a tšepe a ho boloka liqubu a 'nile a tsejoa le ho ntlafatsoa e le mokhoa oa kaho o potlakileng, o sebetsang hantle le o mosa tikolohong.

KOPO

1. Boleng bo holimo (matla a phahameng, boima bo bobebe, tšitiso e ntle ea metsi)

2. Kaho e bonolo le nako e khutsufalitsoeng ea kaho

3. Ho tšoarella hantle, nako ea bophelo ke lilemo tse 20-50

4. Litšenyehelo tsa kaho li theko e tlase

5. E ka fapanyetsana hantle 'me e ka sebelisoa hape ka makhetlo a 3-5

HO PHAKISA LE HO ROMELA

Polokelo:

1. Ha ho hlongoa, kaho ea nakong e tlang e tlameha ho nahanoa, 'me tatellano, sebaka, tataiso le moralo oa ho hlongoa ha liqubu tsa tšepe li tlameha ho khethoa ka nepo. Karolo ea pele e sebelisitsoeng e beoa ka ntle, 'me likarolo tse sebelisitsoeng hamorao li ka beoa kahare. Sena ke ho nolofatsa lipalangoang ha li sebelisoa.

2. Mefuta e fapaneng ea liqubu tsa tšepe e lokela ho beoa ka thoko 'me ha ea lokela ho beoa ka mokhoa o ratang. Li lokela ho aroloa ho latela litlhaloso tse fapaneng, bolelele, jj., 'me libaka tsa ho beoa ka har'a liqubu li lokela ho tšoauoa e le hore li ka fumanoa habonolo ha li sebelisoa. Qubu ea liqubu.

3. Liqubu tsa tšepe li lokela ho beoa ka mekhahlelo. Ka kakaretso, palo ea lera ka leng ha ea lokela ho feta 5. Ho phaella moo, li-rooster li lokela ho beoa pakeng tsa lera ka leng. Sebaka pakeng tsa li-rooster hangata ke limithara tse 3 ho isa ho tse 4, 'me liqubu tse ka holimo le tse ka tlase li lokela ho netefatsoa. Li-rooster lera ka leng li lokela ho ba moleng o le mong o otlolohileng, 'me bolelele bohle ba lera ka kakaretso ha boa lokela ho feta limithara tse peli.

MATLA A K'hamphani

E entsoe Chaena, tšebeletso ea boemo ba pele, boleng bo holimo, e tsebahala lefatšeng ka bophara

1. Phello ea sekala: Khamphani ea rona e na le ketane e kholo ea phepelo le fektheri e kholo ea tšepe, e fihlelang liphello tse kholo lipalangoang le theko, 'me e fetoha k'hamphani ea tšepe e kopanyang tlhahiso le lits'ebeletso.

2. Mefutafuta ya dihlahiswa: Mefutafuta ya dihlahiswa, tshepe efe kapa efe eo o e batlang e ka rekwa ho rona, haholo-holo e sebetsanang le meaho ya tshepe, di-rails tsa tshepe, di-sheet pile tsa tshepe, di-bracket tsa photovoltaic, tshepe ya kanale, di-coil tsa tshepe tsa silicon le dihlahiswa tse ding, e leng se etsang hore e tenyetsehe haholoanyane. Khetha mofuta wa sehlahiswa o lakatsehang ho fihlela ditlhoko tse fapaneng.

3. Phepelo e tsitsitseng: Ho ba le mohala o tsitsitseng oa tlhahiso le ketane ea phepelo ho ka fana ka phepelo e tšepahalang haholoanyane. Sena se bohlokoa haholo ho bareki ba hlokang tšepe e ngata.

4. Tšusumetso ea lets'oao: E na le tšusumetso e phahameng ea lets'oao le 'maraka o moholo

5. Tšebeletso: Khamphani e kholo ea tšepe e kopanyang mokhoa oa ho iketsetsa, lipalangoang le tlhahiso

6. Tlholisano ea theko: theko e utloahalang

*Romella imeile ho[email protected]ho fumana khotheishene bakeng sa merero ea hau

KETO EA BAREKI

LBH

1. Nka fumana khotheishene joang ho tsoa ho uena?

O ka re siela molaetsa, 'me re tla araba molaetsa o mong le o mong ka nako. Kapa re ka buisana inthaneteng ka WhatsApp. Hape o ka fumana tlhahisoleseling ea rona ea ho ikopanya leqepheng la puisano.

2. Na nka fumana disampole pele ke odara?

E, ehlile. Hangata disampole tsa rona ha di lefellwe. Re ka di hlahisa ka disampole tsa hao kapa ka ditshwantsho tsa botekgeniki. Re ka haha dibopeho le disebediswa.

3. Nako ea hau ea ho pepa ke efe?

A. Nako ea ho pepa hangata e ka ba khoeli e le 'ngoe (1 * 40FT joalo ka tloaelo);

B. Re ka romela thepa ka matsatsi a 2, haeba e na le thepa.

4. Melao ea hau ea tefo ke efe?

Nako ea rona ea tefo e tloaelehileng ke depositi ea 30%, 'me karolo e setseng khahlanong le B/L. L/C le eona ea amoheleha.

5. U ka tiisa joang hore seo ke se fumaneng se tla ba molemo?

Re fektheri ka tlhahlobo ea pele ho pepa ea 100% e netefatsang boleng.

'Me joaloka mofani oa khauta ho Alibaba, tiisetso ea Alibaba e tla etsa garantee e bolelang hore alibaba e tla u lefa chelete esale pele, haeba ho na le bothata ka lihlahisoa.

6. U etsa joang hore khoebo ea rona e be ea nako e telele le kamano e ntle?

K. Re boloka boleng bo botle le theko e hlōlisanang ho netefatsa hore bareki ba rona ba rua molemo;

B. Re hlompha moreki e mong le e mong e le motsoalle oa rona 'me re etsa khoebo ka tieo' me re etsa setsoalle le eena ho sa tsotelehe hore na o tsoa hokae