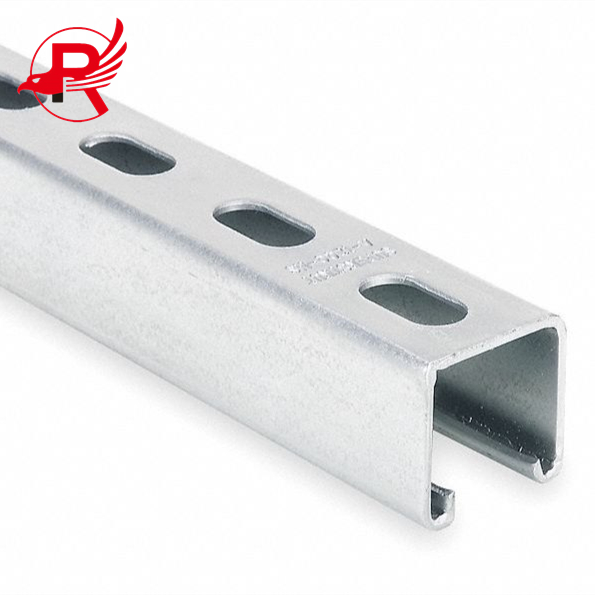

China Factory ea Boleng bo Holimo-limo e nang le Slotted Galvanized Strut Channel Steel Unistrut HDG GI Strut C Channel Steel

Tšepe ea Sebopeho sa C Channel, haholo-holokanale ea ce fana ka melemo e mengata indastering ea kaho. Matla a eona a phahameng, ho boloka litšenyehelo hantle, le bonolo ba ho e kenya li etsa hore e be khetho e ntle bakeng sa mefuta e mengata ea lits'ebetso. Ho feta moo, lesela la galvanized le ntlafatsa ho tšoarella ha eona 'me le sireletsa khahlanong le mafome. Ka thepa e feto-fetohang joalo, li-C-purlin tsa galvanized li fumane sebaka sa tsona e le tharollo e tšepahalang ea kaho mekhoeng ea sejoale-joale ea kaho.

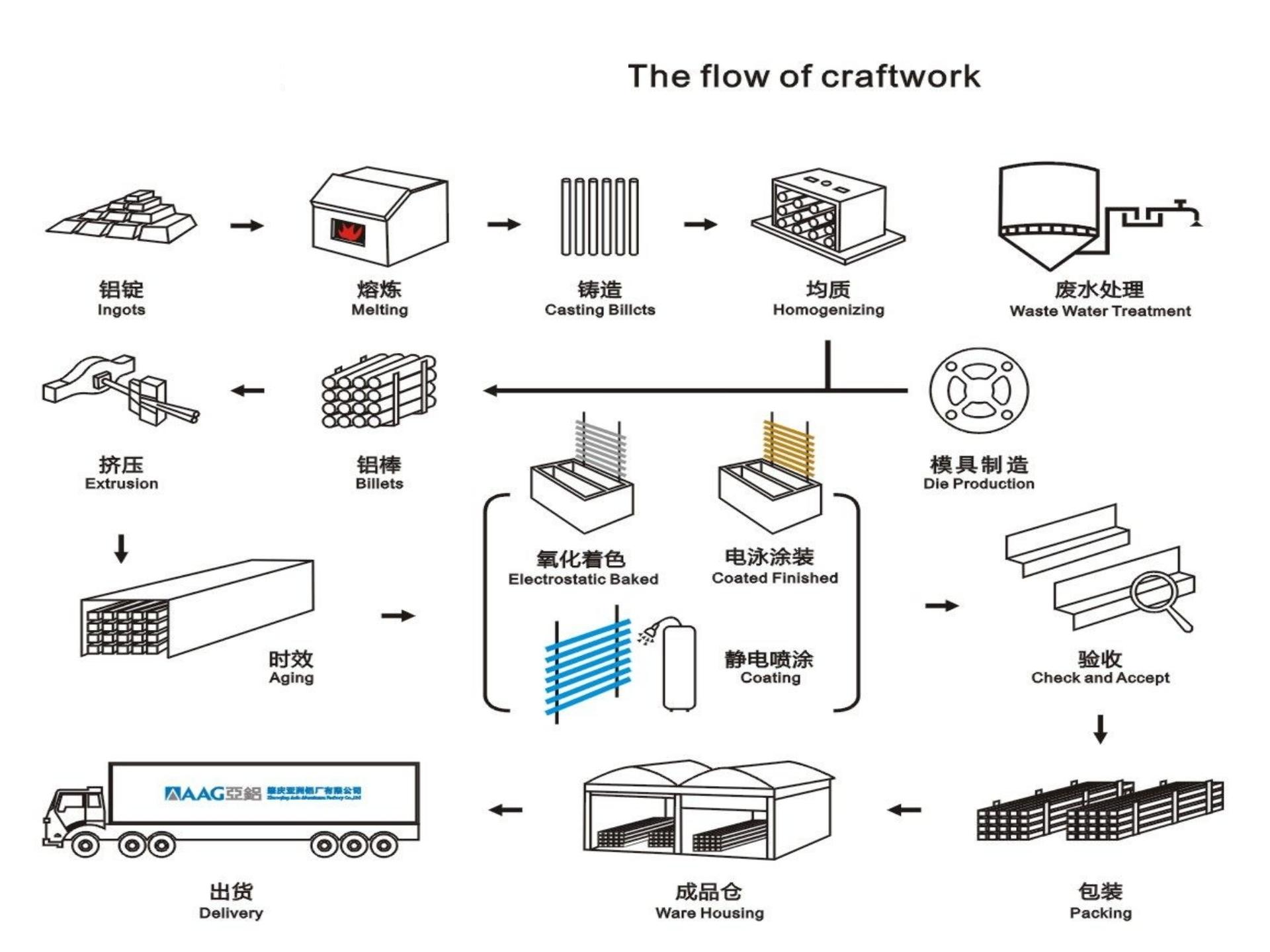

Mokhoa oa Tlhahiso ea Sehlahisoa

BOHOLO BA SEHLAHISOA

| Thepa | Q195/Q235/SS304/SS316/ |

| Botenya | 1.5mm/1.9mm/2.0mm/2.5mm/2.7mm12GA/14GA/16GA/0.079''/0.098'' |

| Moseho | 41*21,/41*41 /41*62/41*82mm e nang le dikotwana kapa e se nang letho 1-5/8'' x 1-5/8'' 1-5/8'' x 13/16'' |

| E tloaelehileng | GB/DIN/ANSI/JIS/ISO |

| Bolelele | 2m/3m/6m/e etselitsoeng motho ka mong10ft/19ft/e etselitsoeng motho ka mong |

| Ho paka | 50 ~ 100pcs e khomaretsoe ka mokotlana oa polasetiki |

| E felile | 1. Tšepe e entsoeng ka galvanized esale pele 2. HDG (Hot dip galvanized) 3. Tšepe e sa ruseng SS304 4. Tšepe e sa ruseng SS316 5. Aluminium 6. Phofo e koahetsoeng |

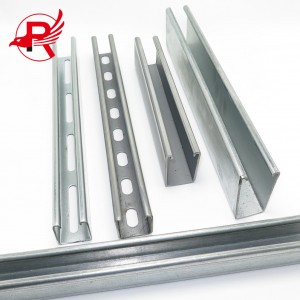

| Tjhe. | Boholo | Botenya | Mofuta | Bokaholimo Kalafo | ||

| mm | intshi | mm | Tekanyo | |||

| A | 41x21 | 1-5/8x13/16" | 1.0,1.2,1.5,2.0,2.5 | 20,19,17,14,13 | E betliloeng, e tiile | GI, HDG, PC |

| B | 41x25 | 1-5/8x1" | 1.0,1.2,1.5,2.0,2.5 | 20,19,17,14,13 | E betliloeng, e tiile | GI, HDG, PC |

| C | 41x41 | 1-5/8x1-5/8" | 1.0,1.2,1.5,2.0,2.5 | 20,19,17,14,13 | E betliloeng, e tiile | GI, HDG, PC |

| D | 41x62 | 1-5/8x2-7/16" | 1.0,1.2,1.5,2.0,2.5 | 20,19,17,14,13 | E betliloeng, e tiile | GI, HDG, PC |

| E | 41x82 | 1-5/8x3-1/4" | 1.0,1.2,1.5,2.0,2.5 | 20,19,17,14,13 | E betliloeng, e tiile | GI, HDG, PC |

MOLEMO

Melemo eaTšepe ea Meaho ea C Channel

Ho atile haholo

Libaka tsa ho kenya tse tenyetsehang

Ho ntlafala ha botsitso ba eneji ya naha

Litšenyehelo tse tlase tsa ts'ebetso le tlhokomelo

Mofuta o tloaelehileng oa sistimi ea ho kenya motlakase ka photovoltaic e sebelisoang bakeng sa litsamaiso tse kholo tsa photovoltaic tse kentsoeng fatše ke sistimi e kholo ea photovoltaic e kentsoeng fatše. Hangata litsamaiso tsena li sebelisa motheo oa konkreite. Mokhoa ona oa ho kenya motlakase o potlakile ho kenngoa 'me o ka sebelisoa le litsamaiso tse kholo tsa photovoltaic tse kentsoeng fatše, ho ntlafatsa tsoelo-pele ea basebetsi ba kaho ea lifeme tsa motlakase, ka hona, o se o sebelisoa haholo. Se boletsoeng ka holimo se thathamisa mefuta e meng ea litsamaiso tsa ho kenya motlakase ka photovoltaic le litšobotsi tsa tsona. Ka nts'etsopele ea indasteri, mofuta ona oa lisebelisoa o tla tuma haholo, kahoo re tlameha ho ba hlokolosi ha re khetha lisebelisoa ho etsa hore maphelo a rona a be bonolo le a sebetsang hantle.

TLHAHLOBO EA SEHLAHISOA

Meaho ea tšehetso ea projeke ea PV ka kakaretso e hahiloe ka thepa ea tšepe ea boleng bo holimo joalo ka motsoako oa aluminium le tšepe e sa ruseng. Pele e isoa tlhahlobong, thepa e tlameha ho netefatsoa hore e latela maemo le melawana ea indasteri ea naha. Ho feta moo, letoto la liteko, ho kenyeletsoa tlhahlobo ea metsoako ea lik'hemik'hale, tlhahlobo ea thepa ea mechini, le tlhokomelo ea sebopeho sa metallographic, lia hlokahala ho netefatsa hore boleng ba thepa bo fihlela litlhoko.

Sebopeho sa tšehetso ke sebopeho sa bohlokoa sa tšehetso bakeng sa li-module tsa PV, 'me matla a sona a sebopeho le botsitso li bohlokoa bakeng sa merero ea tlhahiso ea motlakase ea PV. Nakong ea ts'ebetso ea tlhahlobo, sebopeho sa tšehetso se lekoa bakeng sa moea, tšisinyeho ea lefatše le ho hanyetsa lehloa ho netefatsa botsitso le ts'epo ea sebopeho.

Pele o romela sebopeho sa tšehetso bakeng sa tlhahlobo, ponahalo ea sona e tlameha ho hlahlojoa ho netefatsa hore se phetse hantle ebile ha se na liphoso tse totobetseng. Ho feta moo, sebopeho sa tšehetso se tlameha ho hlahlojoa bakeng sa ho hanyetsa mafome le ho tšoarella ho netefatsa hore se boloka ts'ebetso e ntle ha se sebelisoa nako e telele.

MORERO

Khamphani ea ronaBafepedi ba Tšepe ea C Channele nkile karolo morerong o moholo ka ho fetisisa oa nts'etsopele ea matla a letsatsi Amerika Boroa, e fana ka li-bracket le moralo oa tharollo. Re fane ka lithane tse 15,000 tsa li-bracket tsa photovoltaic bakeng sa projeke ena. Li-bracket tsa photovoltaic li sebelisitse mahlale a macha a lehae ho thusa nts'etsopele ea indasteri ea photovoltaic Amerika Boroa le ho ntlafatsa baahi ba moo. Bophelo. Projeke ea tšehetso ea photovoltaic e kenyelletsa seteishene sa motlakase sa photovoltaic se nang le bokhoni bo kentsoeng ba hoo e ka bang 6MW le seteishene sa motlakase sa polokelo ea matla a betri sa 5MW/2.5h. E ka hlahisa lihora tse ka bang 1,200 kilowatt ka selemo. Sistimi ena e na le bokhoni bo botle ba phetoho ea photoelectric. Haeba u batla ho tseba Litheko tsa Tšepe ea C Channel, ka kopo ikopanye le 'na.

KOPO

C Purline ka kenngwa eseng feela marulelong, empa hape le mobung le metsing. Khetho ea litsamaiso tsa ho kenya motlakase ka photovoltaic e hloka ho nahanoa ka botlalo ka lintlha tse kang bokhoni ba ho jara mojaro, maemo a tikoloho, botsitso, le litšenyehelo tsa kaho le tlhokomelo. Litsamaiso tsa ho kenya motlakase ka photovoltaic tse tsitsitseng le tse matla ka ho lekaneng li ka netefatsa ts'ebetso e tsitsitseng ea nako e telele ea lifeme tsa motlakase ka photovoltaic le ho kenya letsoho haholo ntlafatsong ea matla a nchafatsoang.

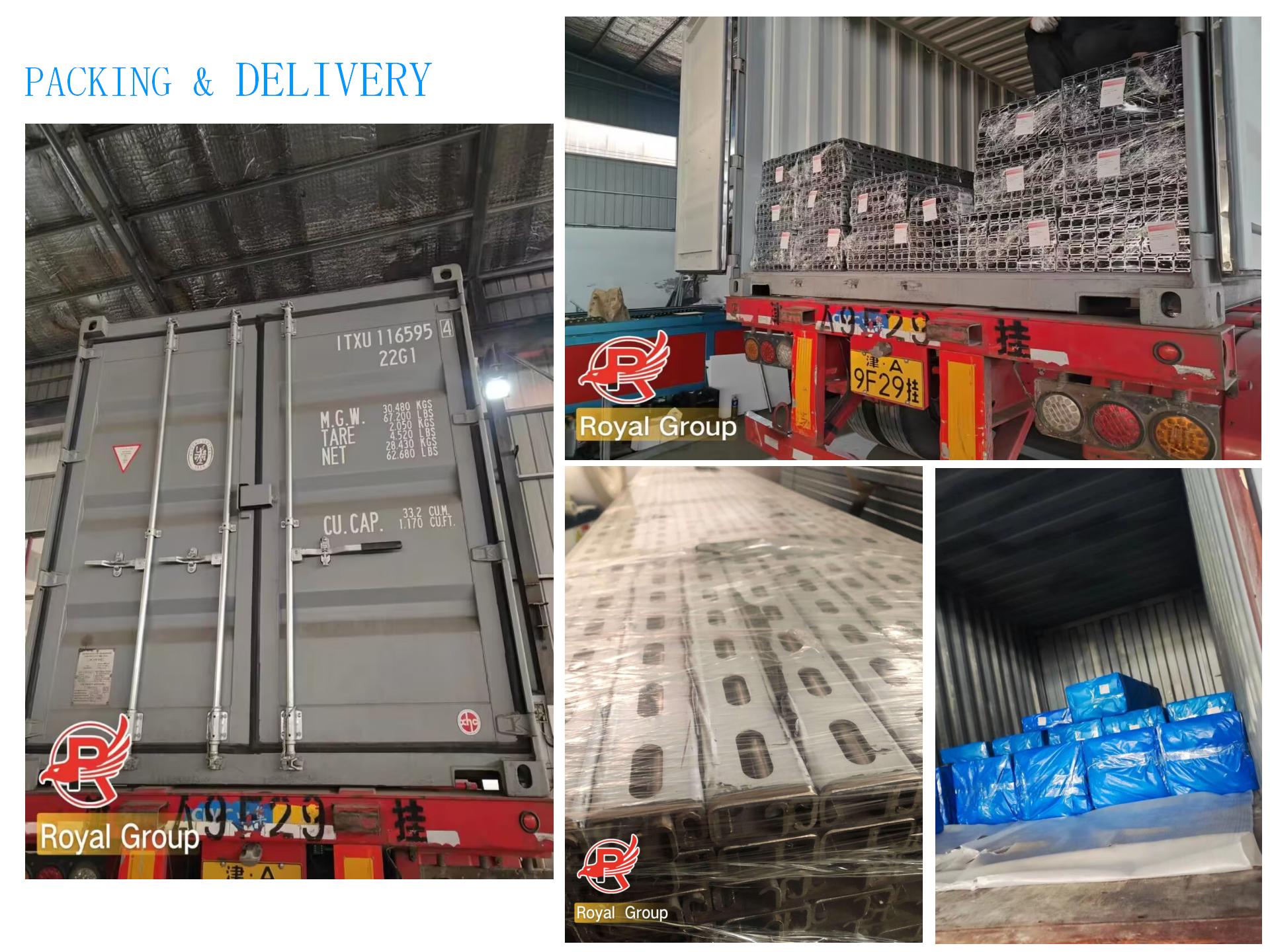

HO PHAKISA LE HO ROMELA

Ho tsamaisa koloi ke e 'ngoe ea mekhoa e sebelisoang haholo ea ho tsamaisa thepac purlinMelemo ea eona e meholo ke ho tloha hang-hang, litsela tse fapaneng, le ho tenyetseha ho matla. Bakeng sa ho tsamaisa li-bracket tse nyane tsa photovoltaic, litšenyehelo tsa ho tsamaisa likoloi li tlase haholo, empa bakeng sa li-bracket tse kholo tsa photovoltaic, litšenyehelo tsa ho tsamaisa likoloi li phahame haholo. Hobane ho tsamaisa li-rack tse kholo tsa photovoltaic ho hloka likoloi tse kholo, 'me litšenyehelo tsa likoloi tse kholo li holimo.

Lipalangoang tsa terene, ka melemo ea tsona ea mantlha ea bokhoni bo matla ba lipalangoang tsa maeto a malelele le palo e kholo ea maeto a le mong, ke tharollo e loketseng bakeng sa lipalangoang tse tšelang libaka tsa litsamaiso tse kholo tsa ho raha tsa photovoltaic. Ha e angoa ke tšubuhlellano ea sephethephethe sa litsela le lithibelo tsa mojaro, e netefatsa katleho e tsitsitseng le polokeho nakong ea lipalangoang tsa maeto a malelele, e leng se etsang hore e tšoanelehe haholo bakeng sa lipalangoang tse kholo ho pholletsa le liprofinse le linaha.

Lipalangoang tsa metsing, tse sebelisang litsela tsa tlhaho tsa metsi tse kang linoka tsa naha, matša le maoatle, li ithorisa ka melemo e meholo bakeng sa lipalangoang tse tsamaeang sebaka se selelele le tse kholo haholo, e leng se etsang hore e lumellane hantle le litlhoko tsa lipalangoang tsa litsamaiso tse kholo tsa ho raha tsa photovoltaic (tse kang mabala a malelele a tšepe le litšiea tse bōpehileng joaloka C). Ha li bapisoa le mekhoa e meng ea lipalangoang, lipalangoang tsa metsi li fana ka melemo e meholo ea litšenyehelo bakeng sa lipalangoang tse tsamaeang sebaka se selelele tsa thepa e ngata, 'me mokhoa oa eona o boreleli oa lipalangoang o fokotsa tšenyo ea litsamaiso tsa ho raha tse bakoang ke moferefere. E loketse merero e meholo libakeng tsa lebopong le lebopong la noka, hammoho le ho pholletsa le meeli.

MATLA A K'hamphani

E entsoe Chaena, tšebeletso ea boemo ba pele, boleng bo holimo, e tsebahala lefatšeng ka bophara

1. Phello ea sekala: Khamphani ea rona e na le ketane e kholo ea phepelo le fektheri e kholo ea tšepe, e fihlelang liphello tse kholo lipalangoang le theko, 'me e fetoha k'hamphani ea tšepe e kopanyang tlhahiso le lits'ebeletso.

2. Mefutafuta ya dihlahiswa: Mefutafuta ya dihlahiswa, tshepe efe kapa efe eo o e batlang e ka rekwa ho rona, haholo-holo e sebetsanang le meaho ya tshepe, di-rails tsa tshepe, di-sheet pile tsa tshepe, di-bracket tsa photovoltaic, tshepe ya kanale, di-coil tsa tshepe tsa silicon le dihlahiswa tse ding, e leng se etsang hore e tenyetsehe haholoanyane. Khetha mofuta wa sehlahiswa o lakatsehang ho fihlela ditlhoko tse fapaneng.

3. Phepelo e tsitsitseng: Ho ba le mohala o tsitsitseng oa tlhahiso le ketane ea phepelo ho ka fana ka phepelo e tšepahalang haholoanyane. Sena se bohlokoa haholo ho bareki ba hlokang tšepe e ngata.

4. Tšusumetso ea lets'oao: E na le tšusumetso e phahameng ea lets'oao le 'maraka o moholo

5. Tšebeletso: Khamphani e kholo ea tšepe e kopanyang mokhoa oa ho iketsetsa, lipalangoang le tlhahiso

6. Tlholisano ea theko: theko e utloahalang

*Romella imeile ho[email protected]ho fumana khotheishene bakeng sa merero ea hau

KETO EA BAREKI

LBH

1. Re bo-mang?

Re lula Tianjin, Chaena, ho tloha ka 2012, re rekisa Asia Boroa-bochabela (20.00%), Asia Boroa (20.00%), Europe Boroa (10.00%), Europe Bophirimela (10.00%), Afrika (10.00%), Amerika Leboea (25.00%), Amerika Boroa (5.00%). Ho na le batho ba ka bang 51-100 ofising ea rona.

2. Re ka netefatsa boleng joang?

Kamehla mohlala oa pele ho tlhahiso pele ho tlhahiso e kholo;

Tlhahlobo ea ho qetela kamehla pele ho romelloa;

3. o ka reka eng ho rona?

Liphaephe tsa Tšepe, Likhutlo tsa Tšepe, Libalaka tsa Tšepe, Meaho ea Tšepe e Welded, Lihlahisoa tsa Tšepe tse nang le Menoko

4. Ke hobane'ng ha u lokela ho reka ho rona eseng ho bafepedi ba bang?

Boleng bo holimo; Theko ea tlholisano; Nako e khuts'oane ea ho fana; Tšebeletso e khotsofetseng; E entsoe ho latela maemo a fapaneng

5. Re ka fana ka lits'ebeletso life?

Melao ea ho Romela e Amohetsoeng: FOB, CFR, CIF;

Chelete ea Tefo e Amohetsoeng: USD, CNY;

Mofuta oa Tefo o Amohetsoeng: T/T;

Puo e Buuoang: Senyesemane, Sechaena