Fektheri e tobileng ea GB Standard Round Bar e boloka chelete e ngata

Molamu oa tšepeke mofuta oa thepa ea tšepe e nang le matla a phahameng le ho hanyetsa ho bola.

Hangata e sebelisoa kahong, mechine, likepe le liindasteri tse ling. Lefapheng la kaho, lithupa tsa tšepe li ka sebelisoa ho matlafatsa mehaho ea konkreite e kang litepisi, Marokho, fatše, joalo-joalo. Melamu ea tšepe e ka boela ea sebelisoa ho etsa likarolo tsa mechine, tse kang li-bearing, li-gears, li-bolts, joalo-joalo.

Lintlha tsa molamu oa tšepe hangata li kenyelletsa lintlha tse latelang: bophara, bolelele ba mahlakoreng, bolelele, joalo-joalo tse boletsoeng ho latela litlhoko tsa boenjiniere.

MOKHOA OA SEHLAHISO

1. Tokisetso ea lisebelisoa tse tala

1. Khetho ea thepa: Khetha tšepe ea boleng bo holimo e nang le boleng bo botle, ha e na sekala sa oxide, ha e na mapetso kapa mapetso, le litšila tse fokolang e le lisebelisoa tse tala.

2. Ho Seha: Seha thepa e tala ka bolelele le bophara bo loketseng, ho etsa bonnete ba hore sebaka se sehang se khanya ebile ha se na mapetso.

2. Ho hloekisa

1. Ho tlosa litšila: Sebelisa separola sa makenete kapa ho hlopha ka letsoho ho tlosa litšila linthong tse tala.

2. Preheating: ho futhumatsa lisebelisoa tse tala ho mocheso o itseng ka sebōping bakeng sa ts'ebetso e latelang.

3. Ho hloekisoa: Kenya lintho tse tala tse chesitsoeng ka sebōping sa ho hloekisa bakeng sa phekolo ea mocheso o phahameng ho tlosa lintho tse kotsi tse kang carbon, sebabole le phosphorus linthong tse tala, 'me u lokise carbon content.

3. Ho sebetsa le ho theha

1. Preforming: Ho lokisa lisebelisoa tse tala tse hloekisitsoeng ka mekoallo ea sebopeho se itseng.

2. Phekolo ea mocheso: Chesa molamu o entsoeng esale pele ho mocheso o itseng 'me u o boloke ka nako e itseng ho lokisa thepa ea mochine oa molamu.

3. Ho pholisa: Beha molamu o futhumetseng moeeng hore o pholile ka tlhaho.

4. Qetello: Thetšepe e chitjae tsoela pele ho sebetsa hantle joalo ka ho seha terata le ho belisoa ho fihlela boleng bo holimo le boleng bo holimo.

TŠEHLA SEHOLO

| TSEBISO TSA STEELE KHABANE | |

| 1. Boholo | 1) 6-12M kapa tlhoko ea moreki |

| 2) Diameter: customized | |

| 3) Steel Bar,Square / Rectangular Bar,Bara ea tšepe e holofetseng | |

| 2. Maemo: | ASTM, DIN, GB, JIS,EN |

| 3.Material | Q235,Q355,20,45,40Cr,HRB400,HRB500 |

| 4. Sebaka sa feme ea rona | Tianjin, China |

| 5. Tšebeliso: | 1) Mohaho o tiileng oa mohaho |

| 2) Ho sebetsa le ho etsa likarolo tsa mochini | |

| 3) Ho etsa li-bearings | |

| 6. Ho roala: | 1) Ho lla 2) Pente e ntšo (seaparo sa varnish) 3) galvanized |

| 7. Mokhoa: | ho chesa ho biditsoe |

| 8. Mofuta: | Sebaka sa tšepe sa Carbon |

| 9. Sebopeho sa Karolo: | chitja |

| 10. Tlhahlobo: | Tlhahlobo kapa tlhahlobo ea moreki ke motho oa boraro. |

| 11. Thomello: | Setshelo, Sejana se Seholo. |

| 12. Mabapi le Boleng ba Rona: | 1) Ha ho na tšenyo, ha ho kobehile 2) Mahala bakeng sa oli & ho tšoaea 3) Thepa eohle e ka hlahlojoa ke tlhahlobo ea motho oa boraro pele e romelloa |

| Tafole ea thepa ea tšepe e chitja | |||||

| bophara mm | Karolo cm² | boima ba lihlopha kg/m | bophara mm | Karolo cm² | boima ba lihlopha kg/m |

| 6 | 0.283 | 0.222 | (45) | 15.9 | 12.5 |

| 7 | 0.385 | 0.302 | 46 | 16.6 | 13.0 |

| 8 | 0.503 | 0.395 | 48 | 18.1 | 14.2 |

| 9 | 0.636 | 0.499 | 50 | 19.6 | 15.4 |

| 10 | 0.785 | 0.617 | (52) | 21.2 | 16.7 |

| 11 | 0.950 | 0.746 | 55 | 23.8 | 18.7 |

| 12 | 1.13 | 0.888 | 56 | 24.6 | 19.3 |

| 13 | 1.33 | 1.04 | 60 | 28.3 | 22.2 |

| (14) | 1.54 | 1.21 | 64 | 32.2 | 25.3 |

| 16 | 2.01 | 1.58 | 65 | 33.2 | 26.0 |

| (18) | 2.55 | 2.00 | (68) | 36.3 | 28.5 |

| 19 | 2.84 | 2.23 | 70 | 38.5 | 30.2 |

| 20 | 3.14 | 2.47 | 75 | 44.2 | 34.7 |

| 22 | 3.80 | 2.98 | 80 | 50.3 | 39.5 |

| 24 | 4.52 | 3.55 | 85 | 56.8 | 44.6 |

| 25 | 4.91 | 3.85 | 90 | 63.6 | 49.9 |

| (27) | 5.73 | 4.50 | 95 | 70.9 | 55.6 |

| 28 | 6.16 | 4.83 | 100 | 78.5 | 61.7 |

| 30 | 7.07 | 5.55 | 110 | 95.0 | 74.6 |

| 32 | 8.04 | 6.31 | 120 | 113 | 88.7 |

| (33) | 8.55 | 6.71 | 130 | 133 | 104 |

| 36 | 10.2 | 7.99 | 140 | 154 | 121 |

| 38 | 11.3 | 8.90 | 150 | 177 | 139 |

| (39) | 11.9 | 9.38 | 160 | 201 | 158 |

| 42 | 13.9 | 10.9 | 180 | 255 | 200 |

| 200 | 314 | 247 | |||

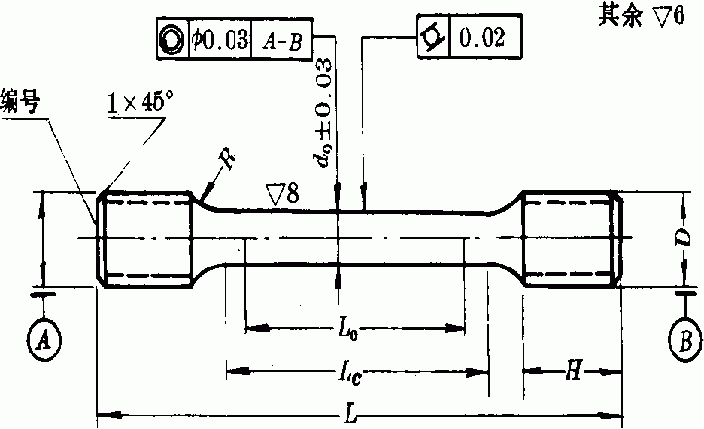

GB Standard Round Bar

Litlhaloso: Q235, Q355,20,45,40Gr

E tloaelehileng: GB/T 1499.2-2007

GB/T 1499.3-2010

Boholo: 6-12M kapa tlhoko ea moreki

| Boholo ba bophara (mm) | Boima ka mithara (kg/m | Likotoana ka bongata | Boima ba 'mele ka bongata ba 12 metara (metric tonne) |

| 5.5 | 0.187 | 450 | 1.010 |

| 6.0 | 0.222 | 375 | 0.999 |

| 6.5 | 0.260 | 320 | 0.998 |

| 7.0 | 0.302 | 276 | 1.000 |

| 8.0 | 0.395 | 200 | 0.948 |

| 9.0 | 0.499 | 168 | 1.006 |

| 10.0 | 0.617 | 138 | 1.022 |

| 12.0 | 0.888 | 96 | 1.023 |

LIKAROLOANA

GB Standard Round Barna le matla a phahameng le boima. Ha li bapisoa le lisebelisoa tse ling, lithupa tsa tšepe li matla 'me li khona ho mamella matla le likhatello tse kholoanyane. Sena se lumella melamu ea tšepe hore e be le karolo e ntlafetseng mererong e fapaneng, e fana ka tšehetso e tsitsitseng le e ka tšeptjoang.

Lithupa tsa tšepe li na le khanyetso e ntle ea kutu. Melamu ea tšepe e ka mamella ho pepeseha ha nako e telele tikolohong e thata joalo ka mongobo, asiti le alkali ntle le tšenyo. Sena se lumella molamu oa tšepe hore o boloke ts'ebetso ea oona le botsitso libakeng tse sa tšoaneng, ho lelefatsa bophelo ba tšebeletso.

Molamu oa tšepe o boetse o na le machinability e ntle. Melamu ea tšepe e ka sebetsanoa le ho bōptjoa ka phekolo ea mocheso, ho sebetsa ka serame, joalo-joalo, ho finyella litlhoko tse fapaneng tsa boenjiniere le tsa tlhahiso. Sena se lumella lithupa tsa tšepe hore li sebelisoe habonolo mererong e fapaneng, ho ntlafatsa katleho ea mosebetsi le boleng.

Melamu ea tšepe e na le mefuta e mengata ea tšebeliso le melemo. Lefapheng la kaho, tlhahiso ea mechine le lipalangoang, lithupa tsa tšepe li phetha karolo ea bohlokoa. Matla a eona a phahameng, ho hanyetsa kutu le machinability a etsa hore lithupa tsa tšepe e be khetho e nepahetseng ea thepa ho fana ka tšehetso e tsitsitseng, e tšepahalang le e tšoarellang. Melamu ea tšepe e na le litebello tse pharaletseng tsa ts'ebeliso mafapheng a fapaneng 'me e tla tsoela pele ho phetha karolo ea bohlokoa.

KOPO

Mehaho le meaho:carbon steel bar e chitjae ka sebelisoa bakeng sa ho matlafatsa le ho tšehetsa meaho le meaho ea meaho, joalo ka ho matlafatsa maballo a konkreite, litšiea le metheo.

litsela le Marokho: Lithupa tsa tšepe li ka sebelisoa bakeng sa kaho ea litsela le Borokho, joalo ka ts'ehetso le matlafatso ea li-pier, li-arches tsa borokho, lithanele le litselana tsa terene.

Likoloi le Likoloi: Lithupa tsa tšepe li ka sebelisoa ha ho etsoa likoloi le likoloi tse ling tse kang ho matlafatsa mabili, chassis le meaho ea 'mele.

Tlhahiso: Lithupa tsa tšepe li sebelisoa haholo indastering ea tlhahiso 'me li ka sebelisoa ho etsa mechini, lisebelisoa le lisebelisoa tse kang lisebelisoa tsa feme, mechini ea temo le lisebelisoa tsa ho seha.

Aerospace: Lithupa tsa tšepe li ka sebelisoa indastering ea sepakapaka, mohlala ha ho etsoa meaho le likaroloana tsa lifofane, lirokete le lisathelaete.

Thepa ea ka tlung le mokhabiso: Lithupa tsa tšepe li ka sebelisoa bakeng sa thepa ea ka tlung le ho khabisa, tse kang ho etsa litafole, litulo, liforeimi tsa libethe le mabone.

Lisebelisoa tsa lipapali: Lithupa tsa tšepe li ka sebelisoa ho etsa lisebelisoa tsa lipapali, tse kang lihlopha tsa kolofo, li-racket tsa tennis le liforeimi tsa libaesekele.

Ka kakaretso, lithupa tsa tšepe li phetha karolo ea bohlokoa haholo liindastering le masimong a sa tšoaneng, 'me matla a tsona a phahameng, ho hanyetsa kutu le polasetiki li etsa hore e be thepa ea bohlokoa haholo.

PHAKALA LE TS'EPE

Sephutheloana:

Tšepe rod stack e tiileng:tšepe e pota-potiloeng ke tšepe e chitjastack ka makhethe, tsitsitseng, ho etsa bonnete ba hore tšepe molamu lolamisiwa, ho thibela tšepe molamu ho hloka botsitso. Sebelisa marapo kapa li-binding ho boloka stack le ho thibela motsamao nakong ea lipalangoang.

Sebelisa liphutheloana tse sireletsang: Koahela lithupa tsa tšepe ka thepa e thibelang mongobo, joalo ka polasetiki kapa pampiri e sa keneleng metsi, ho li sireletsa metsing, mongobo le linthong tse ling tsa tikoloho. Sena se tla thusa ho thibela mafome le kutu.

Ho tsamaisa ka sekepe:

Khetha mokhoa o nepahetseng oa ho tsamaisa: Ho ea ka palo le boima ba lithupa tsa tšepe, khetha mokhoa o nepahetseng oa lipalangoang, joalo ka literaka tsa flatbed, lijana, likepe, joalo-joalo Nahana ka lintlha tse kang sebaka, nako, litšenyehelo le melao ea sephethephethe.

Sebelisa lisebelisoa tse loketseng tsa ho phahamisa: Ha ho laela le ho laolla lithupa tsa tšepe, lisebelisoa tse loketseng tsa ho phahamisa li lokela ho sebelisoa, tse kang li-crane, li-forklift, li-loaders, joalo-joalo Netefatsa hore thepa e sebelisoang e na le matla a lekaneng a ho sebetsana ka mokhoa o sireletsehileng boima ba lere la tšepe.

Mojaro o tsitsitseng: Sebelisa marapo, lithapo kapa mekhoa e meng e loketseng ho tiisa ka nepo litšepe tse pakiloeng ka har'a koloi ea lipalangoang ho thibela ho sisinyeha, ho thella kapa ho oela nakong ea lipalangoang.

KAMPANI MATLA

E entsoe Chaena, tšebeletso ea boemo ba pele, boleng bo holimo, bo tsebahalang lefatšeng ka bophara

1. Tšusumetso ea sekhahla: Khampani ea rona e na le ketane e kholo ea phepelo le fektheri e kholo ea tšepe, e finyellang liphello tse kholo ho lipalangoang le ho reka, 'me e fetoha k'hamphani ea tšepe e kopanyang tlhahiso le litšebeletso.

2. Phapang ea lihlahisoa: Mefuta e sa tšoaneng ea lihlahisoa, tšepe leha e le efe eo u e batlang e ka rekoa ho rona, haholo-holo e sebetsanang le mehaho ea tšepe, litšepe tsa tšepe, liphahlo tsa letlapa la tšepe, li-brackets tsa photovoltaic, tšepe ea channel, li-coil tsa tšepe tsa silicon le lihlahisoa tse ling, e leng se etsang hore e be bonolo haholoanyane Khetha mofuta oa sehlahisoa o lakatsehang ho finyella litlhoko tse fapaneng.

3. Phepelo e tsitsitseng: Ho ba le mohala o tsitsitseng oa tlhahiso le ketane ea phepelo ho ka fana ka phepelo e tšepahalang haholoanyane. Sena ke sa bohlokoa haholo ho bareki ba hlokang lisebelisoa tse ngata tsa tšepe.

4. Tšusumetso ea Brand: E-ba le tšusumetso e phahameng ea lihlahisoa le 'maraka o moholoanyane

5. Tšebeletso: Khampani e kholo ea tšepe e kopanyang ho iketsetsa, lipalangoang le tlhahiso

6. Tlholisano ea theko: theko e utloahalang

* Romella lengolo-tsoibila ho[imeile e sirelelitsoeng]ho fumana quotation bakeng sa merero ea hau

BAKENGI LEETE

LBH

1. Nka fumana mantsoe a qotsitsoeng joang ho uena?

U ka re siela molaetsa, 'me re tla araba molaetsa o mong le o mong ka nako.

2.Na u tla tlisa thepa ka nako?

E, re tšepisa ho fana ka lihlahisoa tsa boleng bo holimo le ho fana ka thepa ka nako. Botšepehi ke molao oa k'hamphani ea rona.

3.Na nka fumana disampole pele odara?

Ehlile ho joalo. Hangata lisampole tsa rona ke tsa mahala, re ka li hlahisa ka lisampole tsa hau kapa lits'oants'o tsa tekheniki.

4.Lipehelo tsa hau tsa tefo ke life?

Nako ea rona e tloaelehileng ea ho patala ke 30% depositi, 'me re phomola khahlanong le B/L. EXW, FOB, CFR, CIF.

5.Na u amohela tlhahlobo ea motho oa boraro?

Ee ruri re amohela.

6.Re tšepa k'hamphani ea hau joang?

Re sebetsa ka ho khetheha khoebong ea tšepe ka lilemo tse ngata re le mofani oa thepa ea khauta, ntlo-khōlō e sebakeng sa setereke sa Tianjin, re amohelehile ho etsa lipatlisiso ka litsela leha e le life, ka mekhoa eohle.