Likarolo tsa Tšepe tsa Sheet tse Ikhethileng Tšebeletso ea ho Tepa Litšepe tsa Sheet Metal tsa Aluminium tse sa Senyeheng

Qaqiso ea Sehlahisoa

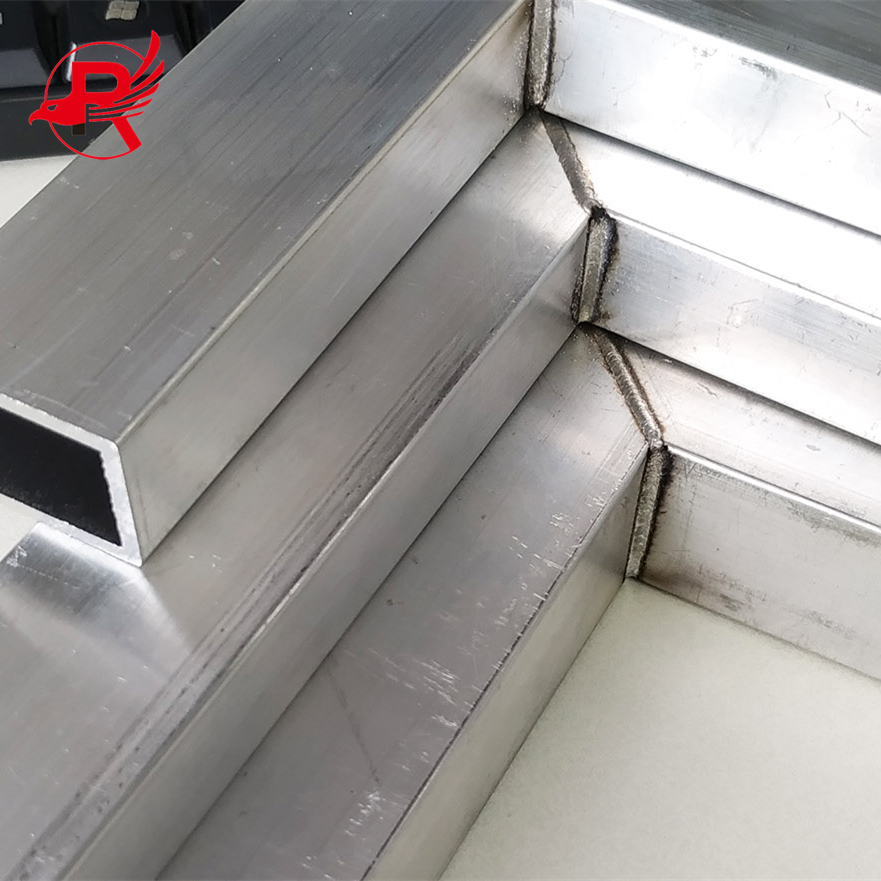

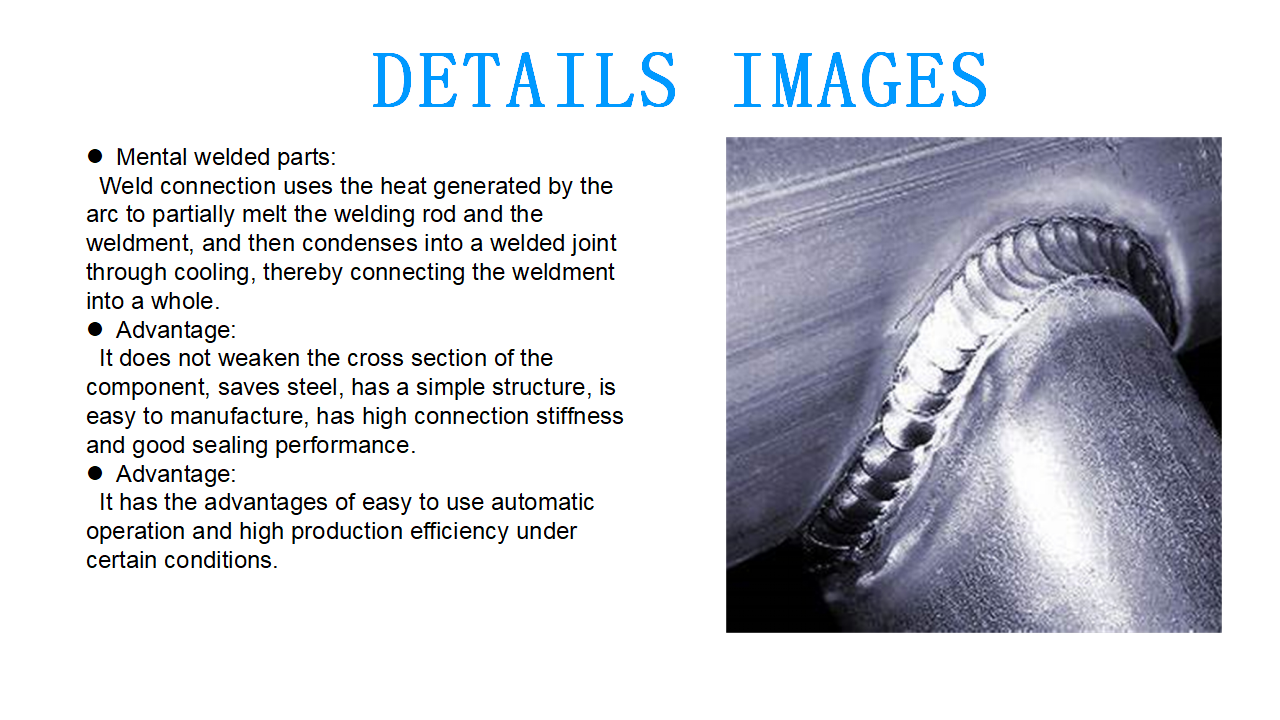

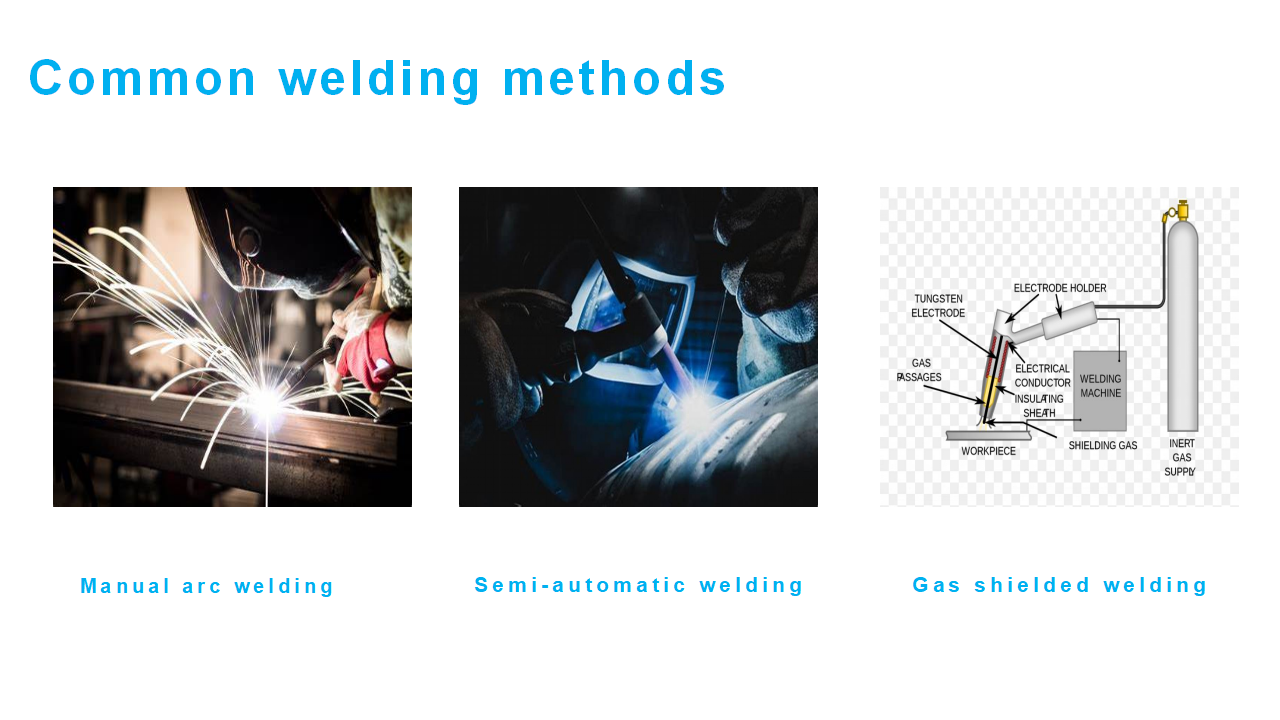

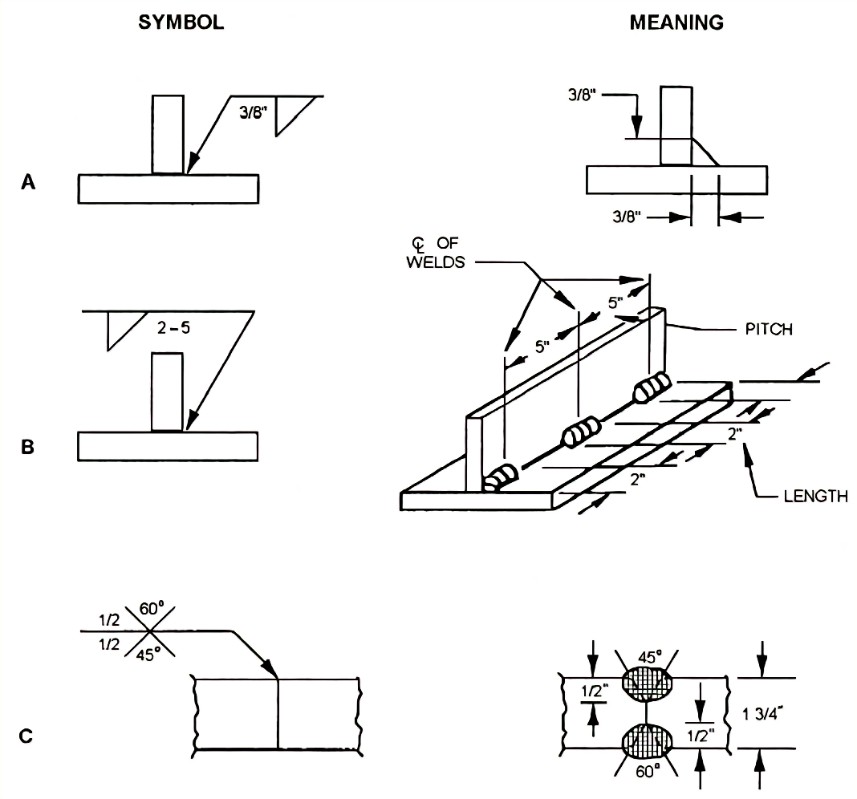

Mekhoa e tloaelehileng ea ho tjheseletsakenyeletsa ho tjheseletsa arc, ho tjheseletsa ka kgase, ho tjheseletsa ka laser, jj. Ho tjheseletsa arc ke e 'ngoe ea mekhoa e sebelisoang haholo ea ho tjheseletsa. Arc e hlahisa mocheso o phahameng ho qhibilihisa thepa ea ho tjheseletsa. E sebelisoa hangata meahong ea tšepe, kahong ea likepe le masimong a mang. Ho tjheseletsa ka khase ho sebelisa khase e sa sebetseng kapa khase e sebetsang ho sireletsa sebaka sa ho tjheseletsa ho thibela oxidation le tšilafalo e 'ngoe. E loketse ho tjheseletsa alloy ea aluminium, tšepe e sa ruseng le thepa e 'ngoe. Ho tjheseletsa ka laser ho sebelisa mahlaseli a laser a matla a mangata ho qhibilihisa le ho kopanya thepa ea ho tjheseletsa. E na le melemo ea ho nepahala ho hoholo le sebaka se senyenyane se amehileng ke mocheso, 'me e loketse ho tjheseletsa ka nepo le tlhahiso e iketsang.

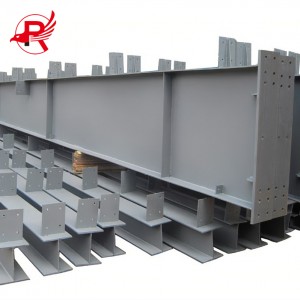

Ho sebetsana le ho tjheseletsae bapala karolo ea bohlokoa indastering ea tlhahiso, e nolofalletsang khokahano le tokiso ea thepa, 'me e sebelisoa haholo lefapheng la lifofane, tlhahiso ea likoloi, boenjiniere ba kaho le masimo a mang. Ka nts'etsopele e tsoelang pele ea theknoloji, ts'ebetso ea ho tjheseletsa le eona e ntse e nchafala kamehla. Tšebeliso ea mahlale a theknoloji e phahameng joalo ka ho tjheseletsa ka laser le ho tjheseletsa ka arc ea plasma e fana ka likhetho le menyetla e mengata bakeng sa indasteri ea tlhahiso.

Ha ho tluoa tabeng ea ho sebetsa ka tšepe, ho tjheseletsa ke ts'ebetso ea bohlokoa e lumellang ho thehoa ha meaho e matla le e tšoarellang. Hore na o hloka lits'ebeletso tsa ho tjheseletsa tsa aluminium, ts'ebeletso ea ho tjheseletsa tšepe e sa ruseng, kapa lits'ebeletso tse akaretsang tsa ho tjheseletsa tšepe, ho fumana lits'ebeletso tse nepahetseng tsa ho etsa li tjheseletsa ho bohlokoa bakeng sa katleho ea projeke ea hau.

Ho tjheseletsa tšepe ke bokgoni bo ikgethang bo hlokang ho nepahala, boiphihlelo le disebediswa tse nepahetseng. Mona ke moolits'ebeletso tsa tlhahiso ea ho tjheseletsaLitšebeletso tsena lia sebetsa. Litšebeletso tsena li fana ka mefuta e fapaneng ea litharollo bakeng sa litlhoko tse fapaneng tsa ho tjheseletsa, ho tloha tlhahisong e ikhethileng ho isa ho litokisong le tlhokomelong. Hore na u sebetsa morerong o monyane oa DIY kapa boitekong bo boholo ba indasteri, ho ba le phihlello ea lisebelisoa tse tšepahalang tsa tlhahiso ea ho tjheseletsa le boiphihlelo hoa bohlokoa.

Khamphani e 'ngoe e ikhethang tšimong eaho tjheseletsa tšepeKa boinehelo ba bona ho boleng le ho nepahala, ba fana ka mefuta e mengata ea lits'ebeletso tsa ho etsa li-welding ho fihlela litlhoko tse fapaneng tsa bareki ba bona. Ho tloha lits'ebeletsong tsa ho tjheseletsa tsa aluminium ho isa ts'ebeletsong ea ho tjheseletsa tšepe e sa hloekang, ba na le boiphihlelo le lisebelisoa tsa ho sebetsana le merero e fapaneng ea ho tjheseletsa tšepe.

Ha o kgetha tshebeletso ya ho etsa di-welding, ho bohlokwa ho nahana ka boiphihlelo le botumo ba khamphani. Batla mofani wa thepa ya nang le rekoto e pakilweng ya ho fana ka diphetho tsa boleng bo hodimo mme a na le bokgoni ba ho sebetsana le ditlhoko tsa hao tse ikgethang tsa ho etsa di-welding.

Ntle le boiphihlelo, tšebeletso e nepahetseng ea tlhahiso ea ho tjheseletsa e lokela ho beha polokeho le bokgabane pele. Sena se bolela ho latela maemo a indasteri le ho sebelisa mekhoa le lisebelisoa tsa morao-rao ho netefatsa sephetho se setle ka ho fetisisa bakeng sa projeke ea hau.

| Thepa | Lebokose la tšepe/aluminium/koporo/tšepe e sa hloekang/spcc |

| 'Mala | E etselitsoeng uena |

| Ho sebetsa | Ho seha ka laser/Ho phunya ka CNC/Ho kobeha ka CNC/Ho tjheseletsa/Ho penta/Ho kopanya |

| Kalafo ea holim'a metsi | Ho roala ka matla, ho penta ka zinki, ho bentša, ho bentša, borashe, skrine ea tsebo jj. |

| Sebopeho sa ho taka | CAD, PDF, SOLIDworks jj. |

| Setifikeiti | ISO9001:2008 CE SGS |

| Tlhahlobo ea Boleng | gauge ea phini, gauge ea caliper, teko ea ho theola, teko ea ho thothomela, teko ea potoloho ea bophelo ba sehlahisoa, teko ea spray ea letsoai, projektara, tekanyo ea ho lekanya li-caliper tsa mochini, micro caliper, thread miro caliper, pass meter, pass meter jj. |

Hlahisa mohlala

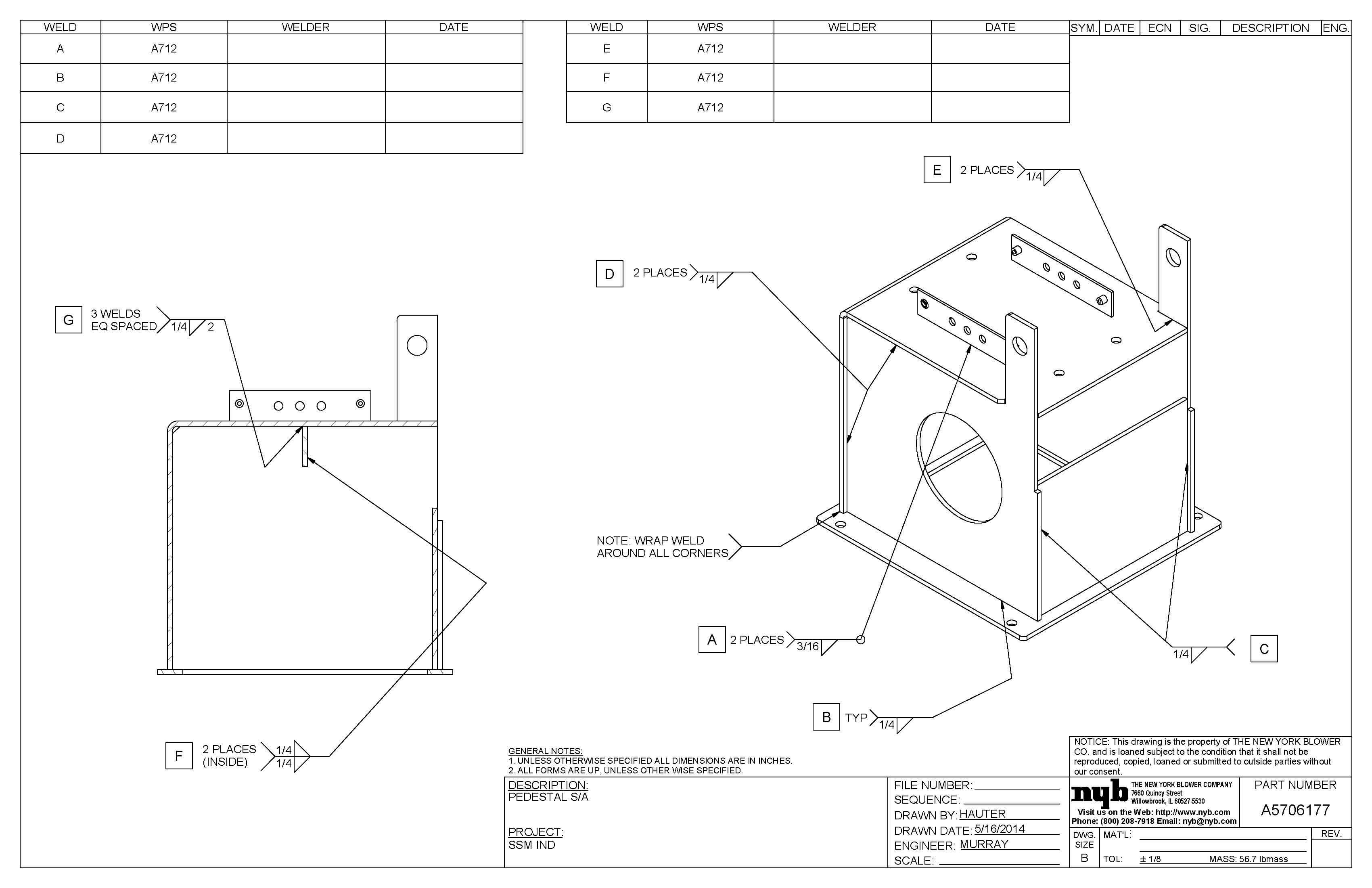

Ena ke odara eo re e fumaneng bakeng sa likarolo tse sebetsanang le tsona.

Re tla hlahisa ka nepo ho latela litšoantšo.

| Likarolo tse Ikhethileng tsa Mechini | |

| 1. Boholo | E etselitsoeng uena |

| 2. Maemo a Tloaelehileng: | E etselitsoeng motho ka mong kapa GB |

| 3. Thepa | E etselitsoeng uena |

| 4. Sebaka sa fektheri ea rona | Tianjin, China |

| 5. Tšebeliso: | Finyella litlhoko tsa bareki |

| 6. Ho roala: | E etselitsoeng uena |

| 7. Mokhoa: | E etselitsoeng uena |

| 8. Mofuta: | E etselitsoeng uena |

| 9. Sebopeho sa Karolo: | E etselitsoeng uena |

| 10. Tlhahlobo: | Tlhahlobo kapa tlhahlobo ea moreki ke motho oa boraro. |

| 11. Thomello: | Setshelo, Sejana se Sengata. |

| 12. Mabapi le Boleng ba Rona: | 1) Ha ho na tshenyo, ha ho na ho kobeha2) Litekanyo tse nepahetseng3) Thepa eohle e ka hlahlojoa ke motho oa boraro pele e romelloa |

Ha feela o na le litlhoko tsa ts'ebetso ea lihlahisoa tsa tšepe tse ikhethileng, re ka li hlahisa ka nepo ho latela litšoantšo. Haeba ho se na litšoantšo, baqapi ba rona le bona ba tla u etsetsa meralo e ikhethileng ho latela litlhoko tsa tlhaloso ea sehlahisoa sa hau.

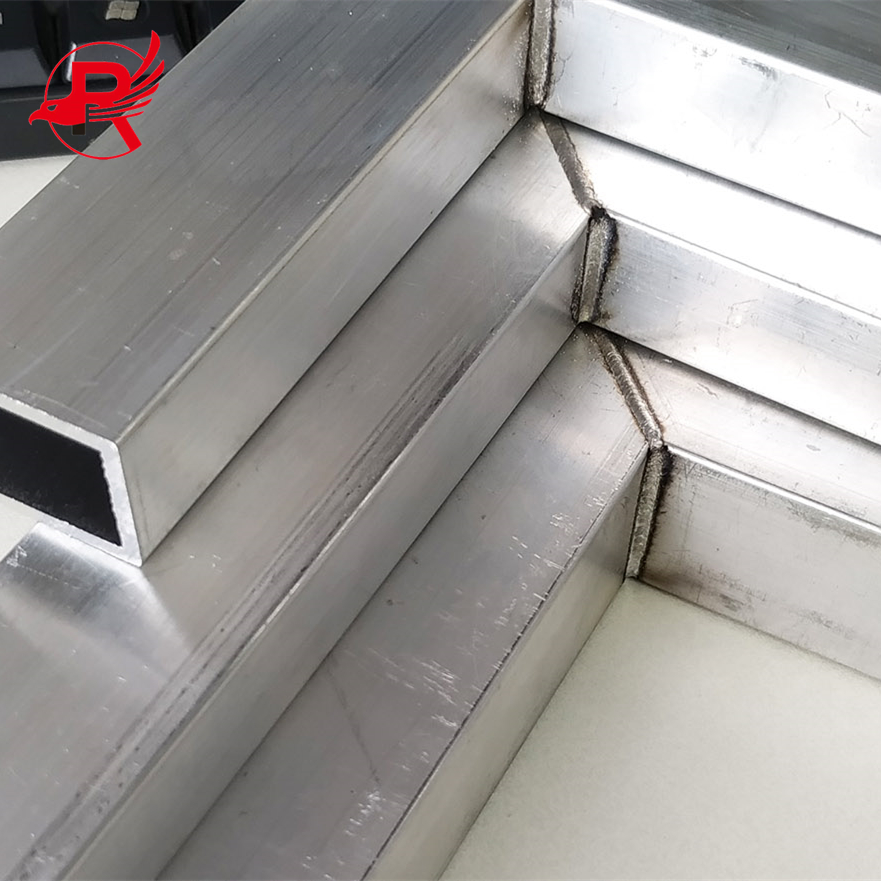

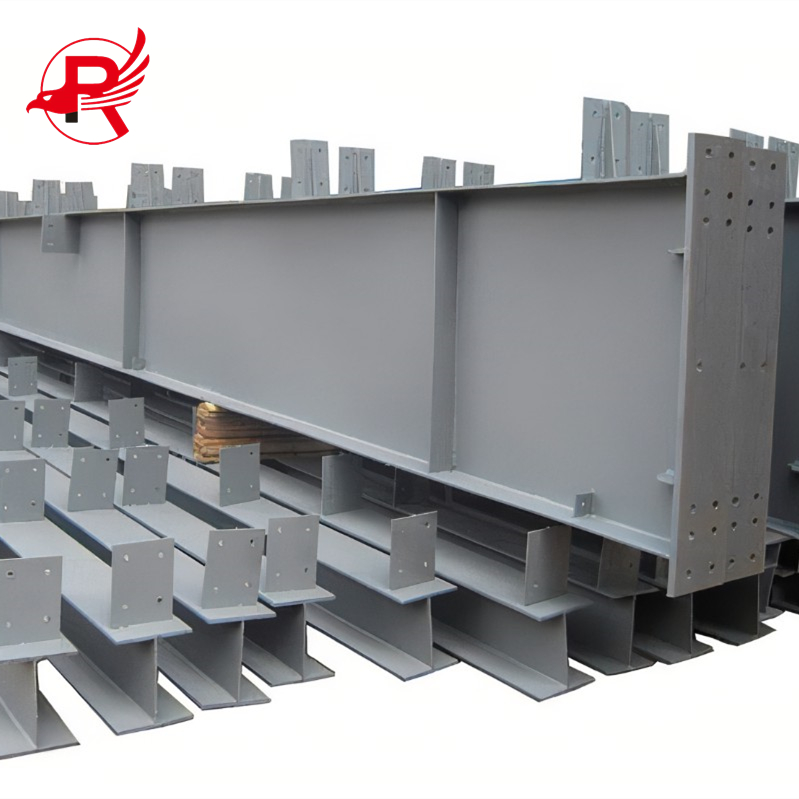

Pontšo ea sehlahisoa se felileng

Ho paka le ho Romela

Sephutheloana:

Re tla paka lihlahisoa ho latela litlhoko tsa bareki, re sebelisa mabokose a lehong kapa lijana, 'me liprofaele tse kholo li tla pakoa ka ho toba li hlobotse, 'me lihlahisoa li tla pakoa ho latela litlhoko tsa bareki.

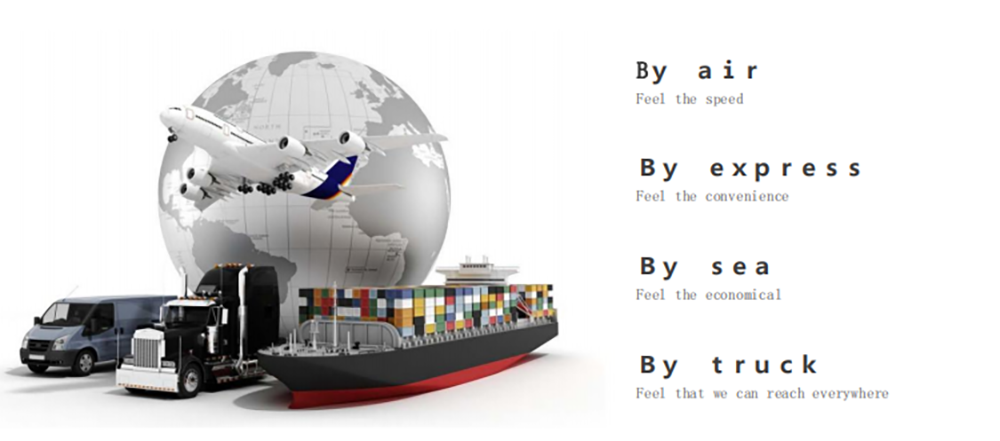

Ho tsamaisa ka sekepe:

Kgetha mokhoa o loketseng wa ho tsamaisa thepa: Ho ya ka bongata le boima ba dihlahiswa tse ikgethileng, kgetha mokhoa o loketseng wa ho tsamaisa thepa, jwalo ka teraka e bataletseng, setshelo kapa sekepe. Nahana ka dintlha tse kang sebaka, nako, ditjeo le ditlhoko dife kapa dife tsa molao bakeng sa ho tsamaisa thepa.

Sebelisa lisebelisoa tse loketseng tsa ho phahamisa: Ho kenya le ho theola likanale tsa strut, sebelisa lisebelisoa tse loketseng tsa ho phahamisa tse kang crane, forklift, kapa loader. Etsa bonnete ba hore lisebelisoa tse sebelisitsoeng li na le bokhoni bo lekaneng ba ho sebetsana ka mokhoa o sireletsehileng le boima ba liqubu tsa maqephe.

Ho Sireletsa Meroalo: Sireletsa hantle mekotla ea lihlahisoa tse entsoeng ka mokhoa o ikhethileng likoloing tsa thepa u sebelisa lithapo, litšepe, kapa mekhoa e meng e loketseng ho thibela ho thula kapa ho senya nakong ea lipalangoang.

LBH

1. Nka fumana khotheishene joang ho tsoa ho uena?

O ka re siela molaetsa, 'me re tla araba molaetsa o mong le o mong ka nako.

2. Na o tla isa thepa ka nako?

E, re tšepisa ho fana ka lihlahisoa tsa boleng bo holimo le ho li tlisa ka nako. Botšepehi ke molao-motheo oa k'hamphani ea rona.

3.Na nka fumana disampole pele ke odara?

E, ehlile. Hangata disampole tsa rona ha di lefellwe, re ka di hlahisa ka disampole tsa hao kapa ka ditshwantsho tsa botekgeniki.

4. Lipehelo tsa hau tsa tefo ke life?

Nako ea rona ea tefo e tloaelehileng ke depositi ea 30%, 'me karolo e setseng khahlanong le B/L.

5. Na o amohela tlhahlobo ea motho oa boraro?

E, ruri rea amohela.

6. Re tšepa khamphani ea hau joang?

Re ikhethile khoebong ea tšepe ka lilemo tse ngata re le mofani oa khauta, ntlo-kholo e profinseng ea Tianjin, re amohelehile ho etsa lipatlisiso ka litsela life kapa life, ka mekhoa eohle.