Thekiso ea Fektheri ea Terata ea Motlakase e 1.6mm 500meter e Tšehelitsoeng Bakeng sa Terata ea Tšireletso Terata ea terata ea aluminium ea terata

Qaqiso ea Sehlahisoa

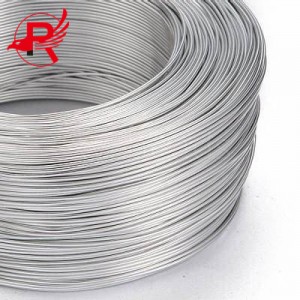

Terata ea aluminium hangata e hlahisoa ka mokhoa o bitsoang ho lahla ka mokhoa o tsoelang pele, moo aluminium e qhibilihisitsoeng e tšeloang ka mokhoa o tsoelang pele ka har'a hlobo ho etsa terata e tiileng. E ka boela ea hlahisoa ka ho ntša metsi, moo aluminium e qobelloang ka har'a see e bōpehileng ho etsa terata e nang le sebopeho se itseng sa karolo e tšekaletseng.

E 'ngoe ea melemo ea bohlokoa ea terata ea aluminium ke boima ba eona bo bobebe ha bo bapisoa le terata ea koporo. Sena se etsa hore ho be bonolo ho e sebetsana le ho e tsamaisa, 'me hape se fokotsa boima ba litsamaiso tsa motlakase ka kakaretso. Ho phaella moo, terata ea aluminium e na le motlakase o motle, leha e le tlase hanyane ho feta oa koporo.

Terata ea aluminium e sebelisoa hangata lits'ebetsong tse fapaneng tsa motlakase, ho kenyeletsoa terata ea matlo le ea khoebo, litsamaiso tsa kabo ea motlakase, lienjene tsa motlakase, li-transformer le lithapo tsa phetisetso ea motlakase tse holim'a metsi. E ka boela ea fumanoa liindastering tse ling tse kang tsa puisano, tsa likoloi, tsa lifofane le tsa kaho.

Leha ho le jwalo, ho bohlokwa ho hlokomela hore terata ya aluminium e na le thepa e fapaneng ya motlakase le ya mechini ha e bapiswa le terata ya koporo. E na le kganyetso e phahameng ya motlakase, e leng se ka fellang ka tahlehelo e eketsehileng ya ho hanyetsa le tlhahiso ya mocheso. Ka hona, mekgwa le dintho tse lokelang ho etswa di lokela ho latelwa ho netefatsa tshebediso e bolokehileng le e sebetsang ya terata ya aluminium ditsamaisong tsa motlakase. Tsena di ka kenyeletsa ho sebedisa boholo bo boholo ba gauge, ho sebedisa dihokelo tse etseditsweng terata ya aluminium ka ho kgetheha, le ho sebedisa insulation le di-termination tse nepahetseng ho fokotsa dikotsi tse amanang le dibopeho tsa terata ya aluminium.

LITLHAKISO TSA TERE EA ALUMINUM

| Lebitso la sehlahisoa | Phaephe ea aluminium |

| Thepa | Aluminium e nang le anodized |

| Boholo | Dia 1.0/1.5/2.0/2.5/3/4-6mm,Ka kopo ikopanye le rona bakeng sa boholo bo ikhethileng |

| MOQ | 100 |

| Tšebeliso ea Sehlahisoa | E ntle haholo bakeng sa ho etsa likarolo tsa mabenyane lipentšele tse phuthetsoeng ka terata |

| Tefo | Tefo ea Alibaba, T/T, western union, moneygram jj. |

| Bophara | 0.05-10 mm |

| Qetello ea Bokaholimo | E foreshe, e bentšitsoeng, e felile ka leloala, e koahetsoe ka motlakase, e phatloha ka lehlabathe |

| Sephutheloana se tloaelehileng | Lipalete tsa lehong, mabokose a lehong kapa ho latela likopo tsa bareki |

KOETSO E IKHETHILENG

Terata ea aluminium e na le mefuta e mengata ea lits'ebetso ho pholletsa le liindasteri tse fapaneng. Tse ling tsa ts'ebeliso e tloaelehileng ea terata ea aluminium ke tsena:

Lithapo tsa Motlakase: Terata ea aluminium hangata e sebelisoa lits'ebetsong tsa lithapo tsa motlakase tsa bolulo, tsa khoebo le tsa indasteri. E ka sebelisoa bakeng sa kabo ea motlakase, mabone le lithapo tsa merero e akaretsang.

Mehala ea Phetiso ea Motlakase e ka Holimo: Terata ea aluminium e sebelisoa hangata bakeng sa mela ea phetiso ea motlakase e kaholimo le ea kabo ka lebaka la ho tsamaisa motlakase ho phahameng, boima bo bobebe le katleho ea litšenyehelo.

Limota tsa Motlakase: Terata ea aluminium e sebelisoa haholo kahong ea limota tsa motlakase, ho kenyeletsoa le limota tsa mechini ea indasteri, lisebelisoa tsa motlakase le likoloi.

Li-Transformer: Terata ea aluminium e sebelisoa likhoeleng tse kobehang tsa li-transformer, e leng likarolo tsa bohlokoa litsamaisong tsa motlakase bakeng sa ho phahamisa kapa ho theola motlakase.

Likhoele le Likhoerekhoere: Terata ea aluminium e sebelisoa tlhahisong ea mefuta e fapaneng ea likhoele le likhoerekhoere, ho kenyeletsoa likhoele tsa motlakase, likhoele tsa taolo le likhoele tsa coaxial.

Mehala ea puisano: Terata ea aluminium e sebelisoa lits'ebetsong tsa puisano ea puisano, ho kenyeletsoa mehala ea mohala le likhoele tsa marang-rang.

Indasteri ea Likoloi: Terata ea aluminium e sebelisoa likarolong tse fapaneng tsa motlakase tsa likoloi, ho kenyeletsoa lithapo tsa terata, lihokelo le li-sensor.

Kaho: Terata ea aluminium e sebelisoa lits'ebetsong tsa kaho tse kang litsamaiso tsa motlakase tsa likhoerekhoere, lits'ebetso tsa HVAC (ho futhumatsa, ho kenya moea o kenang le o pholileng), le lisebelisoa tsa mabone.

Lifofane le Lifofane: Terata ea aluminium e sebelisoa kahong ea lifofane le lifofa-sebakeng ka lebaka la boima ba eona bo bobebe le karolelano e phahameng ea matla ho ea boima.

Litšebeliso tsa Mekhabiso le Bonono: Terata ea aluminium e sebelisoa ke litsebi tsa bonono le litsebi tsa mesebetsi ea matsoho bakeng sa ho etsa liemahale, mabenyane le lintho tse ling tse khabisitsoeng ka lebaka la ho feto-fetoha ha eona le bonolo ba ho e bopa.

Ho paka le ho Romela

Sephutheloana se Seholo: Bakeng sa terata e ngata ea aluminium, sephutheloana se seholo se atisa ho sebelisoa. Sena se kenyelletsa ho kopanya terata hammoho le ho e tiisa ka marapo a polasetiki kapa a tšepe. Terata e kopantsoeng e ka beoa holim'a liphalete bakeng sa ho sebetsana le ho tsamaisoa habonolo.

Lireli kapa Li-spool: Terata ea aluminium hangata e tlamelloa holim'a lireli kapa li-spool bakeng sa ho li aba le ho li boloka habonolo. Terata hangata e tlamelloa ka thata le ho tiisoa ka lithapo kapa li-clip ho thibela ho qhaqhoa. Lireli kapa li-spool li ka etsoa ka polasetiki, lehong, kapa tšepe, ho latela boholo le boima ba terata.

Likhoele kapa Likhoele ka Mabokoseng: Terata ea aluminium e ka kobeha 'me ea siuoa e le likhoele tse hlephileng kapa ea kenngoa ka har'a mabokose bakeng sa tšireletso e eketsehileng. Ho kobeha ho thusa ho fokotsa ho hokahana 'me ho etsa hore terata e be bonolo ho e sebetsana. Likhoele li ka tiisoa ka lithapo kapa likhoele ho li boloka li le sebakeng sa tsona.

Ho paka ntle le ho reel: Bafepedi ba bang ba fana ka dikgetho tsa ho paka ntle le ho reel moo terata ya aluminium e tlangwang ho ba dikhoele ntle le ho sebedisa di-spool kapa di-reel tsa setso. Mokgwa ona o fokotsa ditshila tsa ho paka mme o dumella polokelo le thomello e sebetsang hantle.

Sephutheloana se Sireletsang: Ho sa tsotelehe mokhoa oa ho paka o sebelisitsoeng, ho bohlokoa ho netefatsa hore ho nkuoa mehato e nepahetseng ea tšireletso. Sena se ka kenyelletsa ho sebelisa matsoho a polasetiki kapa a foam ho potoloha terata ho itšireletsa khahlanong le ho ngoatheha le tšenyo nakong ea lipalangoang. Ho feta moo, ho sebelisa thepa e tiileng ea ho paka e kang mabokose a khateboto kapa mabokose a ka ntle ho ka fana ka tšireletso e eketsehileng.