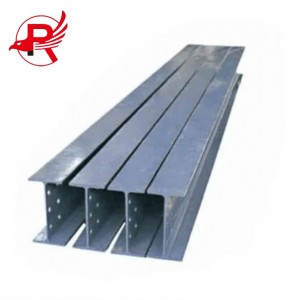

Kaho ea Tšepe e bōpehileng joaloka H ea EN

Lehlaseli la HTšepe e sebelisoa haholo, haholo-holo e sebelisetsoa: meaho e fapaneng ea meaho ea sechaba le ea indasteri; Mefuta e fapaneng ea limela tsa indasteri tse bolelele ba nako e telele le meaho ea sejoale-joale e melelele, haholo-holo libakeng tse nang le ts'ebetso e atisang ho ba teng ea litšisinyeho tsa lefatše le maemo a ts'ebetso a mocheso o phahameng; Marokho a maholo a nang le bokhoni bo boholo ba ho jara, botsitso bo botle ba karolo e tšekaletseng le bolelele bo boholo ba nako; Lisebelisoa tse boima; Tsela e kholo; Masapo a likepe; Tšehetso ea morafo; Kalafo ea motheo le boenjiniere ba matamo; Likarolo tse fapaneng tsa mochini.

Mokhoa oa Tlhahiso ea Sehlahisoa

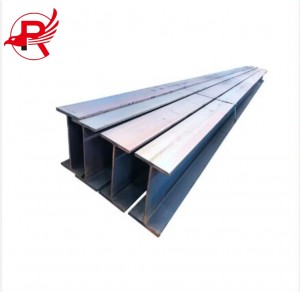

Lehlakore laLehlaseli la He bapile kapa e batla e bapile ka hare le ka ntle, 'me qetello ea flange e ka lehlakoreng le letona, kahoo e bitsoa tšepe ea I-flange e tšoanang. Botenya ba webo ea tšepe e bōpehileng joaloka H bo bonyenyane ho feta ba li-I-beam tse tloaelehileng tse nang le bophahamo bo tšoanang ba webo, 'me bophara ba flange bo boholo ho feta ba li-I-beam tse tloaelehileng tse nang le bophahamo bo tšoanang ba webo, kahoo e boetse e bitsoa li-I-beam tse bophara ba rim. E khethoa ke sebopeho, modulus ea karolo, motsotso oa inertia le matla a tsamaellanang a H-beam li hlakile hore li betere ho feta tsa I-beam e tloaelehileng e nang le boima bo le bong bo tšoanang. E sebelisoa litlhokong tse fapaneng tsa sebopeho sa tšepe, ebang e tlas'a torque e kobehileng, mojaro oa khatello, mojaro o sa tloaelehang o bontša ts'ebetso ea eona e phahameng, e ka ntlafatsa haholo bokhoni ba ho jara ho feta I-beam e tloaelehileng, e boloka tšepe 10% ~ 40%. Tšepe e bōpehileng joaloka H e na le flange e pharaletseng, webo e tšesaane, litlhaloso tse ngata, le ts'ebeliso e tenyetsehang, e ka bolokang 15% ho isa ho 20% ea tšepe meahong e fapaneng ea truss. Hobane flange ea eona e bapile ka hare le ka ntle, 'me pheletso ea moeli e ka lehlakoreng le letona, ho bonolo ho e kopanya le ho e kopanya likarolo tse fapaneng, e leng se ka bolokang hoo e ka bang 25% ea mosebetsi oa ho tjheseletsa le ho roka, 'me e ka potlakisa lebelo la kaho la projeke haholo le ho khutsufatsa nako ea kaho.

BOHOLO BA SEHLAHISOA

| Tlhophiso | Unt Boima ba 'mele kg/m) | Karolo e Tloaelehileng ho ikemela mm | Karolo Ama (cm² | |||||

| W | H | B | 1 | 2 | r | A | ||

| HE28 | AA | 61.3 | 264.0 | 280.0 | 7.0 | 10.0 | 24.0 | 78.02 |

| A | 76.4 | 270.0 | 280.0 | 80 | 13.0 | 24.0 | 97.26 | |

| B | 103 | 280.0 | 280.0 | 10.5 | 18.0 | 24.0 | 131.4 | |

| M | 189 | 310.0 | 288.0 | 18.5 | 33.0 | 24.0 | 240.2 | |

| HE300 | AA | 69.8 | 283.0 | 300.0 | 7.5 | 10.5 | 27.0 | 88.91 |

| A | 88.3 | 200.0 | 300.0 | 85 | 14.0 | 27.0 | 112.5 | |

| B | 117 | 300.0 | 300.0 | 11.0 | 19.0 | 27.0 | 149.1 | |

| M | 238 | 340.0 | 310.0 | 21.0 | 39.0 | 27.0 | 303.1 | |

| HE320 | AA | 74.3 | 301.0 | 300.0 | 80 | 11.0 | 27.0 | 94.58 |

| A | 97.7 | 310.0 | 300.0 | 9.0 | 15.5 | 27.0 | 124.4 | |

| B | 127 | 320.0 | 300.0 | 11.5 | 20.5 | 27.0 | 161.3 | |

| M | 245 | 359.0 | 309.0 | 21.0 | 40.0 | 27.0 | 312.0 | |

| HE340 | AA | 78.9 | 320.0 | 300.0 | 85 | 11.5 | 27.0 | 100.5 |

| A | 105 | 330.0 | 300.0 | 9.5 | 16.5 | 27.0 | 133.5 | |

| B | 134 | 340.0 | 300.0 | 12.0 | 21.5 | 27.0 | 170.9 | |

| M | 248 | 377.0 | 309.0 | 21.0 | 40.0 | 27.0 | 315.8 | |

| HE360 | AA | 83.7 | 339.0 | 300.0 | 9.0 | t2.0 | 27.0 | 106.6 |

| A | 112 | 350.0 | 300.0 | 10.0 | 17.5 | 27.0 | 142.8 | |

| B | 142 | 360.0 | 300.0 | 12.5 | 22.5 | 27.0 | 180.6 | |

| M | 250 | 395.0 | 308.0 | 21.0 | 40.0 | 27.0 | 318.8 | |

| HE400 | AA | 92.4 | 3780 | 300.0 | 9.5 | 13.0 | 27.0 | 117.7 |

| A | 125 | 390.0 | 300.0 | 11.0 | 19.0 | 27.0 | 159.0 | |

| B | 155 | 400.0 | 300.0 | 13.5 | 24.0 | 27.0 | 197.8 | |

| M | 256 | 4320 | 307.0 | 21.0 | 40.0 | 27.0 | 325.8 | |

| HE450 | AA | 99.8 | 425.0 | 300.0 | 10.0 | 13.5 | 27.0 | 127.1 |

| A | 140 | 440.0 | 300.0 | 11.5 | 21.0 | 27.0 | 178.0 | |

| B | 171 | 450.0 | 300.0 | 14.0 | 26.0 | 27.0 | 218.0 | |

| M | 263 | 4780 | 307.0 | 21.0 | 40.0 | 27.0 | 335.4 | |

| Tlhophiso | Yuniti Boima ba 'mele kg/m) | Karolo e Tloaelehileng Ho teba (mm) | Karolo Sebaka (cm²) | |||||

| W | H | B | 1 | 2 | r | A | ||

| HE50 | AA | 107 | 472.0 | 300.0 | 10.5 | 14.0 | 27.0 | 136.9 |

| A | 155 | 490.0 | 300.0 | t2.0 | 23.0 | 27.0 | 197.5 | |

| B | 187 | 500.0 | 300.0 | 14.5 | 28.0 | 27.0 | 238.6 | |

| M | 270 | 524.0 | 306.0 | 21.0 | 40.0 | 27.0 | 344.3 | |

| HE550 | AA | t20 | 522.0 | 300.0 | 11.5 | 15.0 | 27.0 | 152.8 |

| A | 166 | 540.0 | 300.0 | t2.5 | 24.0 | 27.0 | 211.8 | |

| B | 199 | 550.0 | 300.0 | 15.0 | 29.0 | 27.0 | 254.1 | |

| M | 278 | 572.0 | 306.0 | 21.0 | 40.0 | 27.0 | 354.4 | |

| HE60 | AA | t29 | 571.0 | 300.0 | t2.0 | 15.5 | 27.0 | 164.1 |

| A | 178 | 500.0 | 300.0 | 13.0 | 25.0 | 27.0 | 226.5 | |

| B | 212 | 600.0 | 300.0 | 15.5 | 30.0 | 27.0 | 270.0 | |

| M | 286 | 620.0 | 305.0 | 21.0 | 40.0 | 27.0 | 363.7 | |

| HE650 | AA | 138 | 620.0 | 300.0 | t2.5 | 16.0 | 27.0 | 175.8 |

| A | 190 | 640.0 | 300.0 | t3.5 | 26.0 | 27.0 | 241.6 | |

| B | 225 | 660.0 | 300.0 | 16.0 | 31.0 | 27.0 | 286.3 | |

| M | 293 | 668.0 | 305.0 | 21.0 | 40.0 | 27.0 | 373.7 | |

| HE700 | AA | 150 | 670.0 | 300.0 | 13.0 | 17.0 | 27.0 | 190.9 |

| A | 204 | 600.0 | 300.0 | 14.5 | 27.0 | 27.0 | 260.5 | |

| B | 241 | 700.0 | 300.0 | 17.0 | 32.0 | 27.0 | 306.4 | |

| M | 301 | 716.0 | 304.0 | 21.0 | 40.0 | 27.0 | 383.0 | |

| HE800 | AA | 172 | 770.0 | 300.0 | 14.0 | 18.0 | 30.0 | 218.5 |

| A | 224 | 790.0 | 300.0 | 15.0 | 28.0 | 30.0 | 285.8 | |

| B | 262 | 800.0 | 300.0 | 17.5 | 33.0 | 30.0 | 334.2 | |

| M | 317 | 814.0 | 303.0 | 21.0 | 40.0 | 30.0 | 404.3 | |

| HE800 | AA | 198 | 870.0 | 300.0 | 15.0 | 20.0 | 30.0 | 252.2 |

| A | 252 | 800.0 | 300.0 | 16.0 | 30.0 | 30.0 | 320.5 | |

| B | 291 | 900.0 | 300.0 | 18.5 | 35.0 | 30.0 | 371.3 | |

| M | 333 | 910.0 | 302.0 | 21.0 | 40.0 | 30.0 | 423.6 | |

| HEB1000 | AA | 222 | 970.0 | 300.0 | 16.0 | 21.0 | 30.0 | 282.2 |

| A | 272 | 0.0 | 300.0 | 16.5 | 31.0 | 30.0 | 346.8 | |

| B | 314 | 1000.0 | 300.0 | 19.0 | 36.0 | 30.0 | 400.0 | |

| M | 349 | 1008 | 302.0 | 21.0 | 40.0 | 30.0 | 444.2 | |

ENHTšepe e bōpehileng joaloka eona

Sehlopha: EN10034:1997 EN10163-3:2004

Tlhaloso: HEA HEB le HEM

Tekanyetso: EN

LIKAROLOANA

Ho na le litlhaloso tse ngata tsa sehlahisoa saLehlaseli la H, 'me mekhoa ea ho arola ke e latelang.(1) Ho ea ka bophara ba flange ea sehlahisoa, se arotsoe ka flange e pharaletseng, flange e bohareng le flange e tšesaane ea H-beam. Bophara ba flange B ba flange e pharaletseng le flange e bohareng ea H-beam bo boholo ho feta kapa bo lekana le bolelele ba webo H. Bophara ba flange B ba tšepe e tšesaane ea flange e bōpehileng joaloka H bo lekana le hoo e ka bang halofo ea bolelele ba H ba poleiti ea webo.(2) Ho ea ka tšebeliso ea sehlahisoa, se arotsoe ka foreimi ea tšepe ea mofuta oa H, kholomo ea tšepe ea mofuta oa H, qubu ea tšepe ea mofuta oa H le foreimi ea tšepe ea mofuta oa H e nang le flange e teteaneng haholo. Ka linako tse ling tšepe ea channel ea leoto le tšoanang le tšepe ea T-beam e tšoanang le eona e kenyelelitsoe har'a li-beam tsa H. Ka kakaretso, tšepe e tšesaane ea H-beam e sebelisoa e le foreimi 'me tšepe ea H-beam e pharaletseng e sebelisoa e le kholomo. Ka hona, e boetse e tsejoa e le tšepe ea H-beam le tšepe ea H-beam e kholo. (3) Ho ea ka mokhoa oa tlhahiso, e arotsoe ka tšepe ea H-beam e welded le tšepe ea H-beam e phutholohileng. (4) Ho ya ka boholo ba tsona, di arotsoe ka tshepe e kgolo, e mahareng le e nyane e bopehileng jwalo ka H. Ka kakaretso, dihlahiswa tse nang le bolelele ba webe ya H ho feta 700mm di bitswa tse kgolo, 300 ~ 700mm di bitswa tse mahareng, mme tse ka tlase ho 300mm di bitswa tse nyane. Qetellong ya 1990, bolelele ba webe ya H-beam bo boholo ka ho fetisisa lefatsheng ba 1200mm, bophara ba flange ya 530mm.

TLHAHLOBO EA SEHLAHISOA

Litlhoko tsa tlhahlobo ea tšepe e bōpehileng joaloka H li kenyelletsa lintlha tse latelang haholo-holo:

Boleng ba ponahalo: Boleng ba ponahalo ea tšepe e bōpehileng joaloka H bo lokela ho latela maemo a amehang le litlhoko tsa ho hlophisa. Bokaholimo bo lokela ho ba bo boreleli le bo bataletseng, bo se na matheba a totobetseng, mengoapo, mafome le liphoso tse ling.

Litekanyo tsa jeometri: Bolelele, bophara, bophahamo, botenya ba webe, botenya ba flange le litekanyo tse ling tsa tšepe e bōpehileng joaloka H li lokela ho latela maemo a amehang le litlhoko tsa ho odara.

Ho kobeha: Ho kobeha ha tšepe e bōpehileng joaloka H ho lokela ho latela maemo a amehang le litlhoko tsa ho hlophisa. Ho ka bonoa ka ho lekanya hore na lifofane tse lipheletsong ka bobeli tsa tšepe e bōpehileng joaloka H li bapile kapa li sebelisa mithara e kobehang.

Ho sotha: Ho sotha ha tšepe e bōpehileng joaloka H ho lokela ho latela maemo a amehang le litlhoko tsa ho odara. Ho ka bonoa ka ho lekanya hore na lehlakore la tšepe e bōpehileng joaloka H le otlolohile kapa le na le mithara ea ho sotha.

Ho kheloha ha boima: Boima ba tšepe e bōpehileng joaloka H bo lokela ho latela maemo a amehang le litlhoko tsa ho hlophisa. Ho kheloha ha boima ho ka bonoa ka ho bekha.

Sebopeho sa lik'hemik'hale: Haeba tšepe e bōpehileng joaloka H e hloka ho tjhesetsoa kapa ho sebetsoa ka tsela e 'ngoe, sebopeho sa eona sa lik'hemik'hale se lokela ho latela maemo a amehang le litlhoko tsa ho odara.

Litšobotsi tsa mechini: Litšobotsi tsa mechini tsa tšepe e bōpehileng joaloka H li lokela ho latela maemo a amehang le litlhoko tsa ho odara, ho kenyeletsoa matla a ho thapolla, ntlha ea ho ikatisa, bolelele le matšoao a mang.

Teko e sa senyeheng: Haeba tšepe e bōpehileng joaloka H e hloka teko e sa senyeheng, e lokela ho lekoa ho latela maemo a amehang le litlhoko tsa ho odara ho netefatsa hore boleng ba eona ba kahare bo botle.

Ho paka le ho tšoaea: Ho paka le ho tšoaea tšepe e bōpehileng joaloka H ho lokela ho latela maemo a amehang le litlhoko tsa ho odara ho nolofatsa ho tsamaisoa le ho bolokoa.

Ka bokhutšoanyane, litlhoko tse boletsoeng ka holimo li lokela ho nahanoa ka botlalo ha ho hlahlojoa tšepe e bōpehileng joaloka H ho netefatsa hore boleng ba eona bo fihlela maemo a loketseng le litlhoko tsa ho odara, le ho fa basebelisi lihlahisoa tse ntle ka ho fetisisa tsa tšepe e bōpehileng joaloka H.

Kopo

E tloaelehilengLehlaseli la Hthepa ea tšepe e kenyelletsa Q235B, SM490, SS400, Q345 le Q345B. Sebopeho sa lik'hemik'hale le thepa ea mechini ea thepa ena lia fapana, kahoo ha u khetha tšebeliso ea H-beam, hoa hlokahala ho khetha thepa e loketseng ho latela boemo bo itseng.

HO PHAKISA LE HO ROMELA

Sephutheloana le tšireletso:

Ho paka ho bapala karolo ea bohlokoa ho sireletseng boleng ba ASTM A36Lehlaseli la Htšepe nakong ea lipalangoang le polokelo. Thepa e lokela ho tlangwa ka mokhoa o sireletsehileng, ho sebelisoa marapo kapa lithapo tse matla ho thibela motsamao le tšenyo e ka bang teng. Ho feta moo, mehato e lokela ho nkoa ho sireletsa tšepe hore e se ke ea pepesehela mongobo, lerōle le mabaka a mang a tikoloho. Ho phuthela lithapo ka thepa e sa keneleng boemo ba leholimo, joalo ka polasetiki kapa lesela le sa keneleng metsi, ho thusa ho sireletsa khahlanong le mafome le mafome.

LBH

1. Nka fumana khotheishene joang ho tsoa ho uena?

O ka re siela molaetsa, 'me re tla araba molaetsa o mong le o mong ka nako.

2. Na o tla isa thepa ka nako?

E, re tšepisa ho fana ka lihlahisoa tsa boleng bo holimo le ho li tlisa ka nako. Botšepehi ke molao-motheo oa k'hamphani ea rona.

3.Na nka fumana disampole pele ke odara?

E, ehlile. Hangata disampole tsa rona ha di lefellwe, re ka di hlahisa ka disampole tsa hao kapa ka ditshwantsho tsa botekgeniki.

4. Lipehelo tsa hau tsa tefo ke life?

Nako ea rona ea tefo e tloaelehileng ke depositi ea 30%, 'me karolo e setseng khahlanong le B/L. EXW, FOB, CFR, CIF.

5. Na o amohela tlhahlobo ea motho oa boraro?

E, ruri rea amohela.

6. Re tšepa khamphani ea hau joang?

Re ikhethile khoebong ea tšepe ka lilemo tse ngata re le mofani oa khauta, ntlo-kholo e profinseng ea Tianjin, re amohelehile ho etsa lipatlisiso ka litsela life kapa life, ka mekhoa eohle.