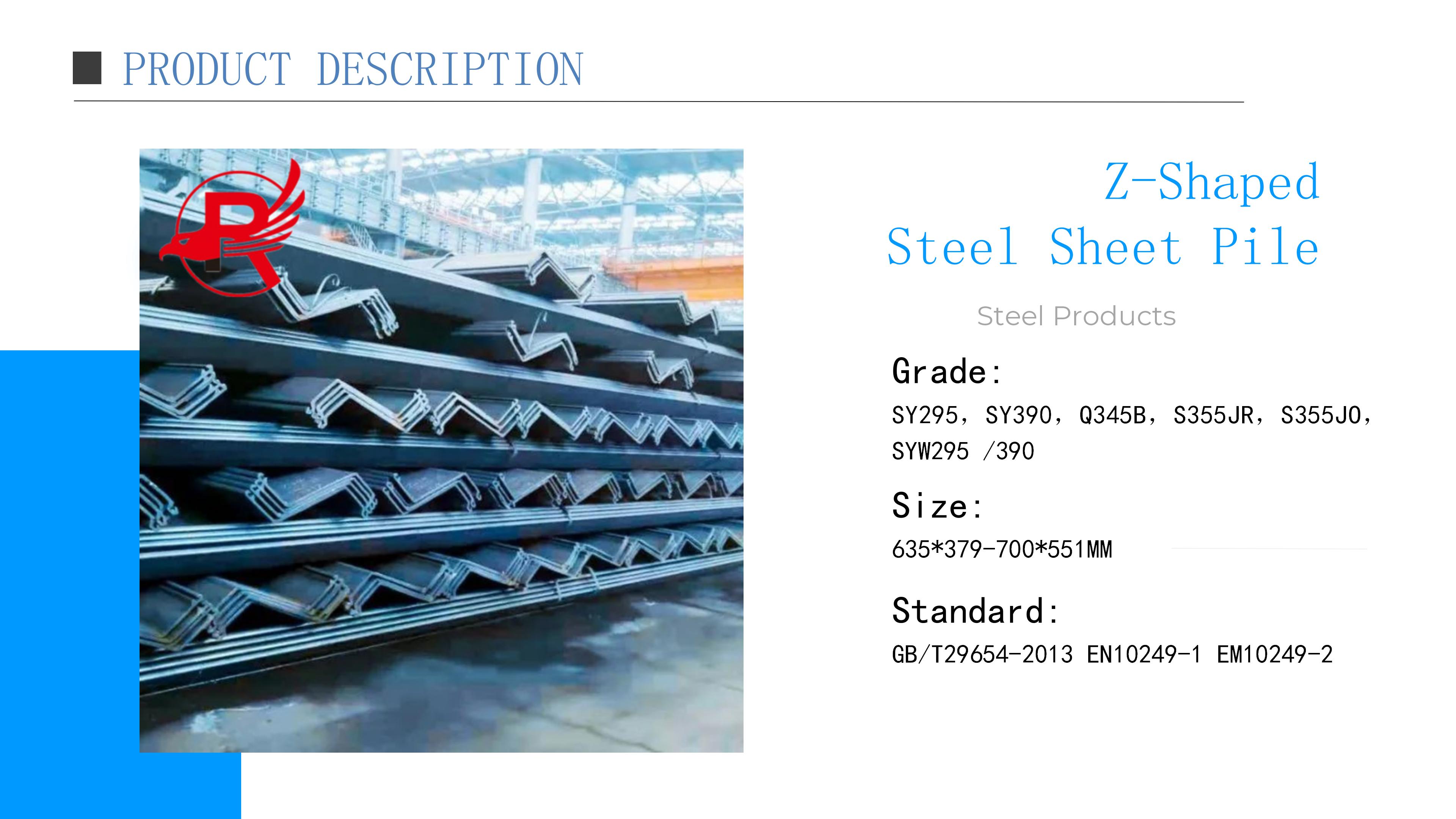

Profaele ea Tšepe ea Hot Z Shape Sheet Pile Sheet Pile ka Theko ea Tlhahiso

Mokhoa oa Tlhahiso ea Sehlahisoa

Ts'ebetso ea tlhahiso ea hot-rolledpampiri ea liqubuhangata e kenyelletsa mehato e latelang:

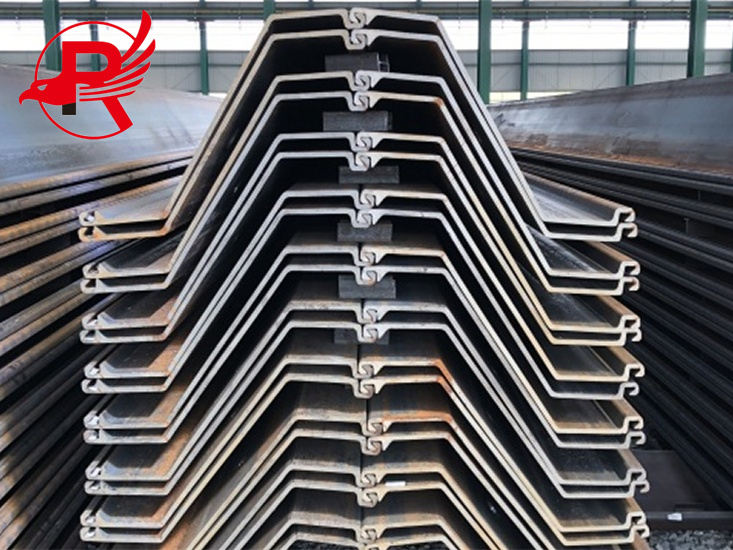

Tokiso ea thepa e tala: Taba ea pele, thepa e tala e hloka ho lokisoa, hangata ho sebelisoa tšepe ea boleng bo holimo e le thepa e tala. Litšepe tsena li hloka ho hlahlojoa le ho hlophisoa ka lihlopha ho netefatsa hore li fihlela litlhoko tsa tlhahiso.

Ho futhumatsa le ho phutholla: Lisebelisoa tse tala li futhumatsoa ho li tlisa mochesong o loketseng ebe li phutholla ka har'a leloala le phuthollang. Ts'ebetsong ena, tšepe e sebetsoa ho baQubu ea Maqephe'me e phutholohile ka makhetlo a mangata ka har'a lirolara tse fapaneng ho netefatsa hore sebopeho le boholo ba sehlahisoa sa ho qetela li fihlela litlhoko tse tloaelehileng.

Ho pholisa le ho bopa: Kamora ho pitikisa, tshepe e hloka ho phodiswa ho tsitsisa sebopeho le thepa ya yona. Ka nako e ts'oanang, ho bopa le ho kuta le hona ho a hlokahala ho netefatsa hore sehlahiswa se na le bokahodimo bo boreledi le boholo bo nepahetseng.

Tlhahlobo le sephutheloana: Se phethiloemochini oa ho bokella lipampiri tsa pampiriho hlokahala hore ho etsoe tlhahlobo e tiileng ea boleng, ho kenyeletsoa le tlhahlobo ea boleng ba ponahalo, ho kheloha ha boholo, metsoako ea lik'hemik'hale, jj. Lihlahisoa tse tšoanelehang li tla be li pakiloe 'me li loketse ho romelloa.

Feme le lipalangoang: Sehlahisoa sa ho qetela se tla kenngoa terakeng ebe se romelloa kantle ho fektheri, se loketse ho romelloa sebakeng sa bareki bakeng sa tšebeliso. Ho lokela ho nkoa tlhokomelo ho sireletsa sehlahisoa nakong ea lipalangoang ho qoba tšenyo.

Se ka holimo ke ts'ebetso e akaretsang ea tlhahiso ea liqubu tsa tšepe tse bōpehileng joaloka Z. Ts'ebetso e itseng ea tlhahiso e ka fapana ho latela moetsi le lisebelisoa.

*Romella imeile ho[email protected]ho fumana khotheishene bakeng sa merero ea hau

| LITLHAKISO TSAQHOBOSHEANE EA LEPARETE LA Z | |

| 1. Boholo | 1) 635*379—700*551mm |

| 2) Botenya ba lebota:4—16MM | |

| 3)Zqubu ea pampiri ea mofuta | |

| 2. Maemo a Tloaelehileng: | GB/T29654-2013 EN10249-1 |

| 3. Thepa | Q235B Q345B S235 S240 SY295 S355 S340 |

| 4. Sebaka sa fektheri ea rona | TianjinChaena |

| 5. Tšebeliso: | 1) setoko se phutholohang |

| 2) Sebopeho sa tšepe sa kaho | |

| 3 Terei ea cable | |

| 6. Ho roala: | 1) E pentiloe ka botšo (seaparo sa varnish) 3) e galvanized |

| 7. Mokhoa: | hot rolled |

| 8. Mofuta: | Zqubu ea pampiri ea mofuta |

| 9. Sebopeho sa Karolo: | Z |

| 10. Tlhahlobo: | Tlhahlobo kapa tlhahlobo ea moreki ke motho oa boraro. |

| 11. Thomello: | Setshelo, Sejana se Sengata. |

| 12. Mabapi le Boleng ba Rona: | 1) Ha ho na tshenyo, ha ho na kobeha 2) Ha e na oli le matshwao 3) Thepa yohle e ka hlahlojwa ke motho wa boraro pele e romelwa |

*Romella imeile ho[email protected]ho fumana khotheishene bakeng sa merero ea hau

| Karolo | Bophara | Bolelele | Botenya | Sebaka se Tšeletseng | Boima ba 'mele | Modulus ea Karolo e Tenyetsehang | Motsotso oa Bofokoli | Sebaka sa ho Koahela (mahlakore ka bobeli ka qubu) | ||

|---|---|---|---|---|---|---|---|---|---|---|

| (w) | (h) | Sekoahelo (tf) | Web (tw) | Ka Phae | Ka Lebota | |||||

| mm | mm | mm | mm | cm²/m | kg/m | kg/m² | cm³/m | cm4/m | m²/m | |

| CRZ12-700 | 700 | 440 | 6 | 6 | 89.9 | 49.52 | 70.6 | 1,187 | 26,124 | 2.11 |

| CRZ13-670 | 670 | 303 | 9.5 | 9.5 | 139 | 73.1 | 109.1 | 1,305 | 19,776 | 1.98 |

| CRZ13-770 | 770 | 344 | 8.5 | 8.5 | 120.4 | 72.75 | 94.5 | 1,311 | 22,747 | 2.2 |

| CRZ14-670 | 670 | 304 | 10.5 | 10.5 | 154.9 | 81.49 | 121.6 | 1,391 | 21,148 | 2 |

| CRZ14-650 | 650 | 320 | 8 | 8 | 125.7 | 64.11 | 98.6 | 1,402 | 22,431 | 2.06 |

| CRZ14-770 | 770 | 345 | 10 | 10 | 138.5 | 83.74 | 108.8 | 1,417 | 24,443 | 2.15 |

| CRZ15-750 | 750 | 470 | 7.75 | 7.75 | 112.5 | 66.25 | 88.34 | 1,523 | 35,753 | 2.19 |

| CRZ16-700 | 700 | 470 | 7 | 7 | 110.4 | 60.68 | 86.7 | 1,604 | 37,684 | 2.22 |

| CRZ17-700 | 700 | 420 | 8.5 | 8.5 | 132.1 | 72.57 | 103.7 | 1,729 | 36,439 | 2.19 |

| CRZ18-630 | 630 | 380 | 9.5 | 9.5 | 152.1 | 75.24 | 119.4 | 1,797 | 34,135 | 2.04 |

| CRZ18-700 | 700 | 420 | 9 | 9 | 139.3 | 76.55 | 109.4 | 1,822 | 38,480 | 2.19 |

| CRZ18-630N | 630 | 450 | 8 | 8 | 132.7 | 65.63 | 104.2 | 1,839 | 41,388 | 2.11 |

| CRZ18-800 | 800 | 500 | 8.5 | 8.5 | 127.2 | 79.9 | 99.8 | 1,858 | 46,474 | 2.39 |

| CRZ19-700 | 700 | 421 | 9.5 | 9.5 | 146.3 | 80.37 | 114.8 | 1,870 | 39,419 | 2.18 |

| CRZ20-700 | 700 | 421 | 10 | 10 | 153.6 | 84.41 | 120.6 | 1,946 | 40,954 | 2.17 |

| CRZ20-800 | 800 | 490 | 9.5 | 9.5 | 141.2 | 88.7 | 110.8 | 2,000 | 49,026 | 2.38 |

Sebaka sa Modulus ea Karolo

1100-5000cm3/m

Bophara ba Bophara (e le 'ngoe)

580-800mm

Botenya ba mefuta e fapaneng

5-16mm

Maemo a Tlhahiso

BS EN 10249 Karolo ea 1 le ea 2

Mekhahlelo ea Tšepe

S235JR, S275JR, S355JR, S355JO

ASTM A572 Gr42, Gr50, Gr60

Q235B, Q345B, Q345C, Q390B, Q420B

Tse ling li fumaneha ha li kopuoa

Bolelele

Bophahamo ba 35.0m empa bolelele bofe kapa bofe bo itseng ba projeke bo ka hlahisoa

Dikgetho tsa Thomello

Ba le bang kapa ba babeli

Lipara li hlephile, li phuthetsoe kapa li koaletsoe

Lesoba la ho Phahamisa

Poleiti ea ho Tšoara

Ka setshelo (11.8m kapa ka tlase ho moo) kapa Break Bulk

Liaparo tsa Tšireletso ea Ts'enyeho

LIKAROLOANA

Kaho e bonolo: Ts'ebetso ea kaho eatšepe ea qubu ea lakanee bonolo ebile e potlakile. O ka sebedisa mokhanni wa qubu o thothomelang kapa mokhanni wa qubu o kgannwang. Tshebetso ena e bonolo haholo mme lebelo la kaho le potlakile, e leng se fokotsang nako ya kaho ya motheo haholo le ho fokotsa ditjeo tsa kaho.

KOPO

E tala ebile e mosa tikolohong: Liqubu tsa tšepe ke thepa e mosa tikolohong e nang le bophelo bo bolelele ba ts'ebeletso 'me e ka sebelisoa hape ka makhetlo a mangata, e leng se phethang karolo ea bohlokoa haholo ho fokotseng tšilafalo ea tikoloho le bongata ba litšila tsa kaho.

HO PHAKISA LE HO ROMELA

1. Sepalangoang sa lijana

Ho tsamaisa lijana ke mokhoa o tloaelehileng oa ho tsamaisa liqubu tsa tšepe 'me o loketse liqubu tse nyane tsa tšepe. Hona joale, lik'hamphani tse ngata li sebelisa lijana tsa lipalangoang tsa leoatleng ho etsa khoebo ea machaba ea liqubu tsa tšepe. Mokhoa ona oa lipalangoang o theko e tlaase, o sebetsa hantle, 'me ha o angoe ke boemo ba leholimo, maemo a litsela le mabaka a mang. Leha ho le joalo, liqubu tse kholo tsa tšepe ha lia lokela ho tsamaisoa ka lijana ka lebaka la boholo ba tsona bo boholo le bothata ba ho fihlela lithibelo tsa boholo ba lijana.

2. Tsamaiso ea bongata

Ho tsamaisa thepa ka bongata ho bolela ho beha liqubu tsa tšepe tse hlobotseng koloing le ho li tsamaisa ntle le sephutheloana. Molemo ke hore ho ka fokotsa litšenyehelo tsa lipalangoang ka tekanyo e kholo, empa ho boetse ho na le kotsi ea tšenyo. Mehato ea ho matlafatsa e hloka ho nkuoa ho fokotsa kotsi, joalo ka ho sebelisa marapo a tlamang ho tiisa liqubu tsa tšepe koloing, 'me koloi e lokela ho khona ho mamella moroalo o boima.

3. Sepalangoang sa literaka tse bataletseng

Ho tsamaisa literaka tse bataletseng ho bolela ho kenya liqubu tsa tšepe literakeng tse bataletseng bakeng sa lipalangoang. Molemo ke hore ho bolokehile ho feta ho tsamaisa ka bongata 'me ho ka tsamaisa liqubu tsa tšepe tse kholo. Ka nako e ts'oanang, mokhoa ona oa lipalangoang o boetse o hloka ts'ebeliso ea mefuta e fapaneng ea literaka tse bataletseng ho latela bolelele le boima ba liqubu tsa tšepe, joalo ka literaka tse bataletseng tse ka huloang le literaka tse bataletseng tse tlase.

4. Lipalangoang tsa terene

Lipalangoang tsa terene li bolela ho kenya liqubu tsa tšepe likoloing tse khethehileng tsa terene bakeng sa lipalangoang. Melemo ke lebelo le potlakileng le litšenyehelo tse tlase, 'me e ka boela ea netefatsa polokeho ea lipalangoang. Leha ho le joalo, tlhokomelo e khethehileng e hloka ho lefshoa ho matlafatsa ho tiea le ho laola lebelo la lipalangoang nakong ea lipalangoang ho fokotsa tšenyo nakong ea lipalangoang.

KETO EA BAREKI

LBH

P1: Khamphani ea hau e etsa mosebetsi oa mofuta ofe?

A1: Re hlahisa haholo-holo liqubu tsa tšepe/li-rails/tšepe ea silicon/tšepe e bōpehileng joaloka eona, jj.

P2: Nako ea hau ea ho tlisa thepa e nka nako e kae?

A2: Ka kakaretso ke matsatsi a 5-10 haeba thepa e le teng. Kapa haeba thepa e se teng, matsatsi a 15-20 ho latela

bongata.

P3: Melemo ea k'hamphani ea hau ke efe?

A3: Khamphani ea rona e na le sehlopha sa litsebi le mela ea tlhahiso ea litsebi.

P4: Na u k'hamphani ea khoebo kapa u moetsi?

A4: Re fektheri.

P5: Lipehelo tsa hau tsa tefo ke life?

A5: Tefo <=1000USD, 100% esale pele. Tefo >= 1000 USD, 30% T/T esale pele,

Haeba o na le lipotso tse ling, ka kopo ikopanye le rona ka mekhoa e latelang.