Terene ea Tšepe ea ISCOR Maemo a Liindasteri Terene e bobebe ea Crane e boima ea Tšepe

Sebopeho sa karolo e tshekaletseng saLitsela tsa Terene ea Tereneke karolo e bōpehileng joaloka I e nang le khanyetso e ntle ka ho fetisisa ea ho kobeha, e entsoeng ka likarolo tse tharo: hlooho ea seporo, letheka la seporo le tlase la seporo. E le ho nolofalletsa seporo ho mamella matla a tsoang likarolong tsohle hamolemo le ho netefatsa maemo a matla a hlokahalang, seporo se lokela ho ba bolelele bo lekaneng, 'me hlooho ea sona le tlase li lokela ho ba le sebaka le bophahamo bo lekaneng. Letheka le tlase ha lia lokela ho ba tšesaane haholo.

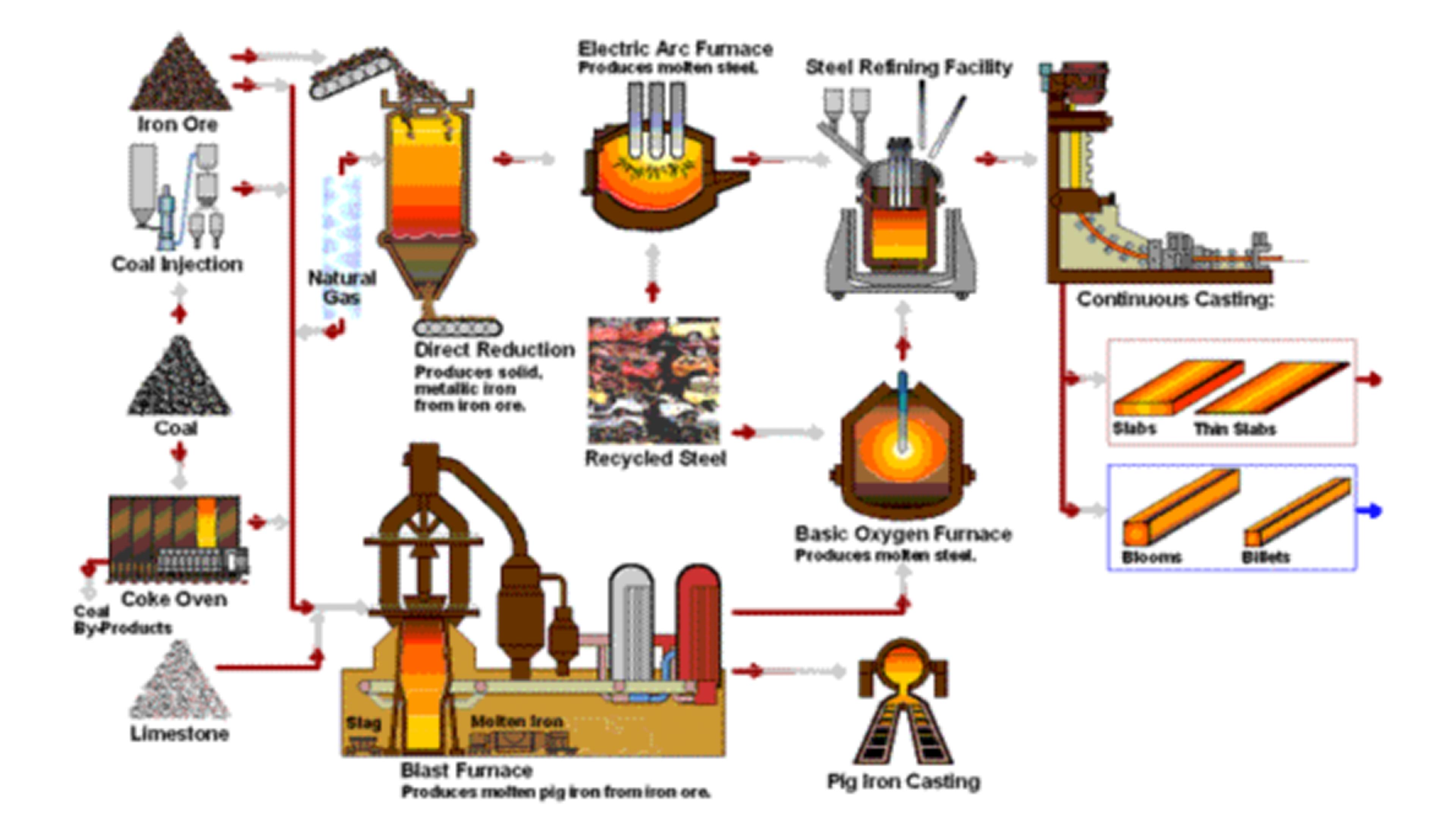

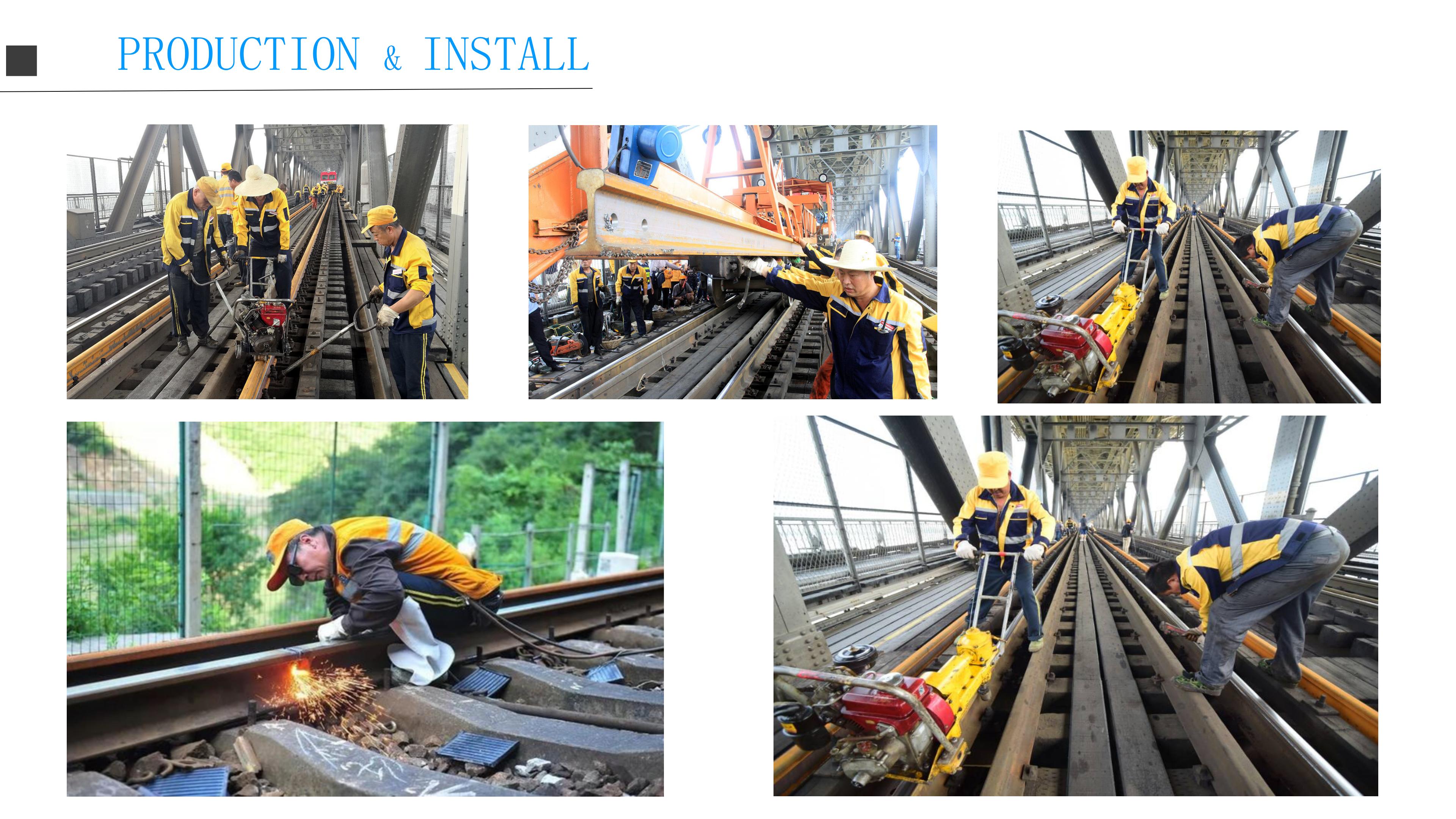

Mokhoa oa Tlhahiso ea Sehlahisoa

Theknoloji le Ts'ebetso ea Kaho

Mokhoa oa ho hahaTsela ea TereneLiterata li kenyelletsa boenjiniere bo nepahetseng le ho nahana ka hloko ka lintlha tse fapaneng. E qala ka ho rala moralo oa literata, ho nahanoa ka tšebeliso e reriloeng, lebelo la terene le sebaka. Hang ha moralo o phethetsoe, ts'ebetso ea kaho e qala ka mehato ea bohlokoa e latelang:

1. Ho Epa le Motheo: Lihlopha tsa kaho li lokisa mobu ka ho epa le ho haha motheo o tiileng ho tšehetsa boima le khatello ea literene.

2. Ho Kenya Ballast: Lera la lejoe le pshatlehileng, le bitsoang ballast, le beoa mobung o lokisitsoeng. Lera lena la lejoe le pshatlehileng le sebetsa e le sesebelisoa sa ho monya tšisinyeho, le fana ka botsitso, 'me le thusa ho aba mojaro ka ho lekana.

3. Dirobalo le ho Lokisa: Dirobalo tsa lehong kapa tsa konkreite di kenngwa hodima ballast ho etsisa sebopeho sa foreimi. Dirobalo tsena di fana ka motheo o tiileng bakeng sa di-rails. Di tiisetswa ka ho sebedisa di-spikes kapa di-clip tse ikgethang ho netefatsa hore di dula di tiile sebakeng sa tsona.

4. Ho Kenya Terene: Lireile tsa tšepe tse bolelele ba limithara tse 10 (tse tsejoang ka hore ke standard gauge) li beoa ka hloko holim'a li-sleepers. Lireile tsena li entsoe ka tšepe ea boleng bo holimo bakeng sa matla le ho tšoarella ho ikhethang.

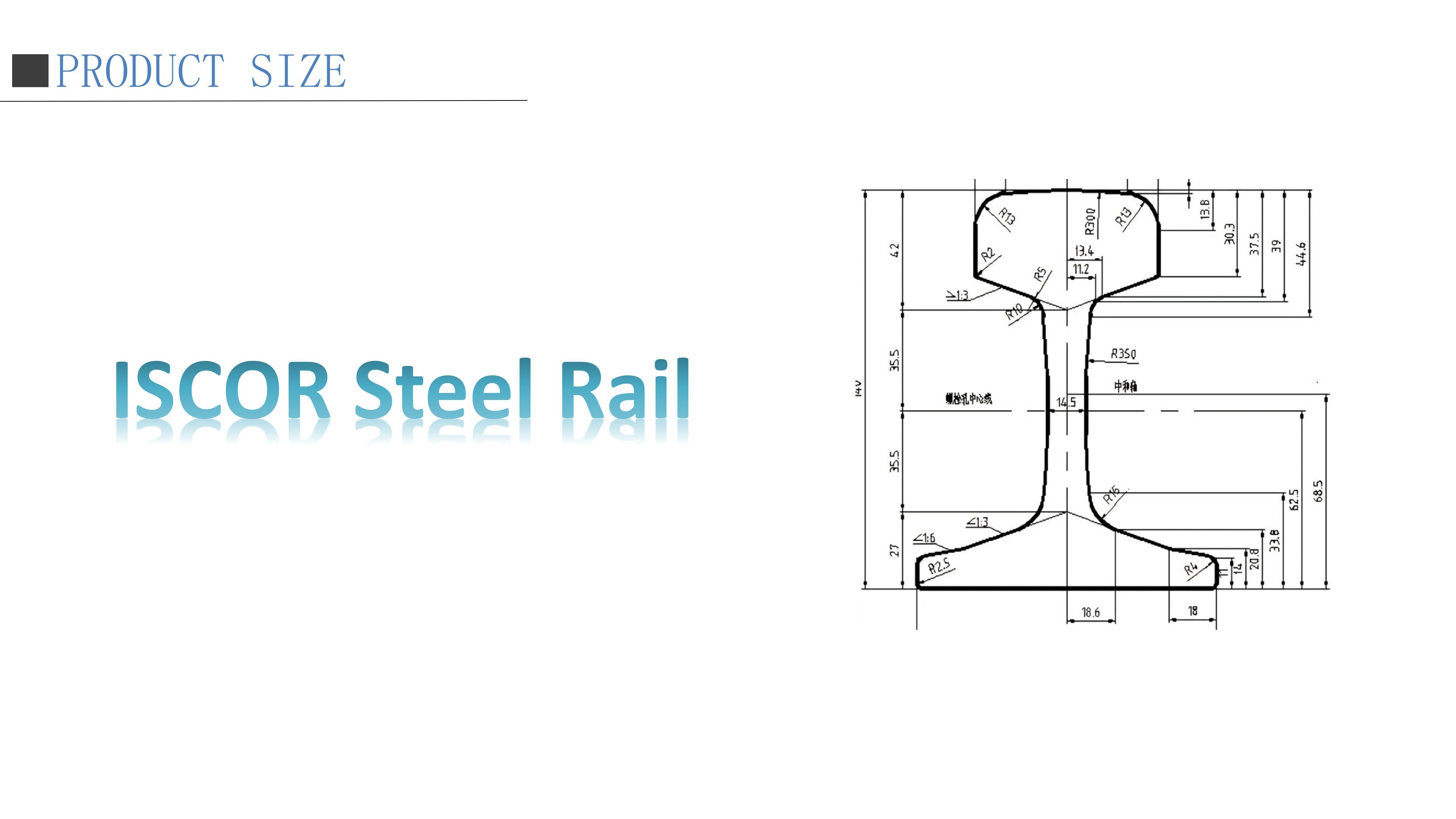

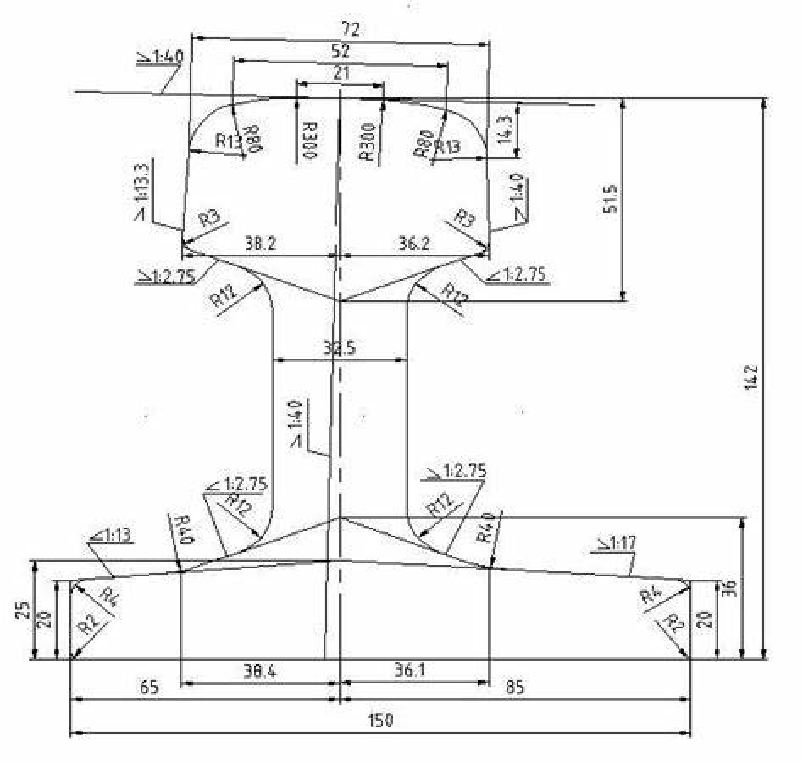

BOHOLO BA SEHLAHISOA

| Terene ea tšepe e tloaelehileng ea ISCOR | |||||||

| mohlala | boholo (mm) | ntho | boleng ba thepa | bolelele | |||

| bophara ba hlooho | bophahamo | boto ea motheo | botebo ba letheka | (kg/m) | (m) | ||

| A(mm) | B(mm) | C(mm) | D(mm) | ||||

| 15KG | 41.28 | 76.2 | 76.2 | 7.54 | 14.905 | 700 | 9 |

| 22KG | 50.01 | 95.25 | 95.25 | 9.92 | 22.542 | 700 | 9 |

| 30KG | 57.15 | 109.54 | 109.54 | 11.5 | 30.25 | 900A | 9 |

| 40KG | 63.5 | 127 | 127 | 14 | 40.31 | 900A | 9-25 |

| 48KG | 68 | 150 | 127 | 14 | 47.6 | 900A | 9-25 |

| 57KG | 71.2 | 165 | 140 | 16 | 57.4 | 900A | 9-25 |

Literene tsa Afrika Boroa:

Litlhaloso: 15kg, 22kg, 30kg, 40kg, 48kg, 57kg

Tekanyetso: ISCOR

Bolelele: 9-25m

MOLEMO

Litšobotsi tsaTsela ea Terene

1. Matla a Phahameng: Ka lebaka la moralo oa tsona o ntlafalitsoeng le mokhoa o khethehileng oa ho etsa thepa, literene li na le matla a ho kobeha le a ho hatella, li khona ho mamella meroalo e boima ea terene le litšitiso, ho netefatsa hore literene li tsamaisoa ka mokhoa o sireletsehileng le o tsitsitseng.

2. Ho Hanela ho Tshwara: Bothata bo phahameng ba bokahodimo ba diterene le khohlano e tlase di hanela ho tsofala ha mabili le diterene tsa terene, e leng se eketsang bophelo ba tsona ba tshebeletso.

3. Ho Tsitsisa ho Hotle: Ditekanyo tse nepahetseng tsa jeometri tsa literene le litekanyo tse tsitsitseng tse otlolohileng le tse otlolohileng li netefatsa ts'ebetso e boreleli ea terene le ho fokotsa lerata le ho thothomela.

4. Kaho e Bonolo: Literene li ka hokahanngoa bolelele bofe kapa bofe ka ho sebelisa manonyeletso, e leng se etsang hore ho kenngoa le ho nkeloa sebaka ho be bonolo haholoanyane.

5. Litšenyehelo tse Tlase tsa Tlhokomelo: Literene li tsitsitse ebile lia tšepahala nakong ea lipalangoang, e leng se fellang ka litšenyehelo tse tlase tsa tlhokomelo.

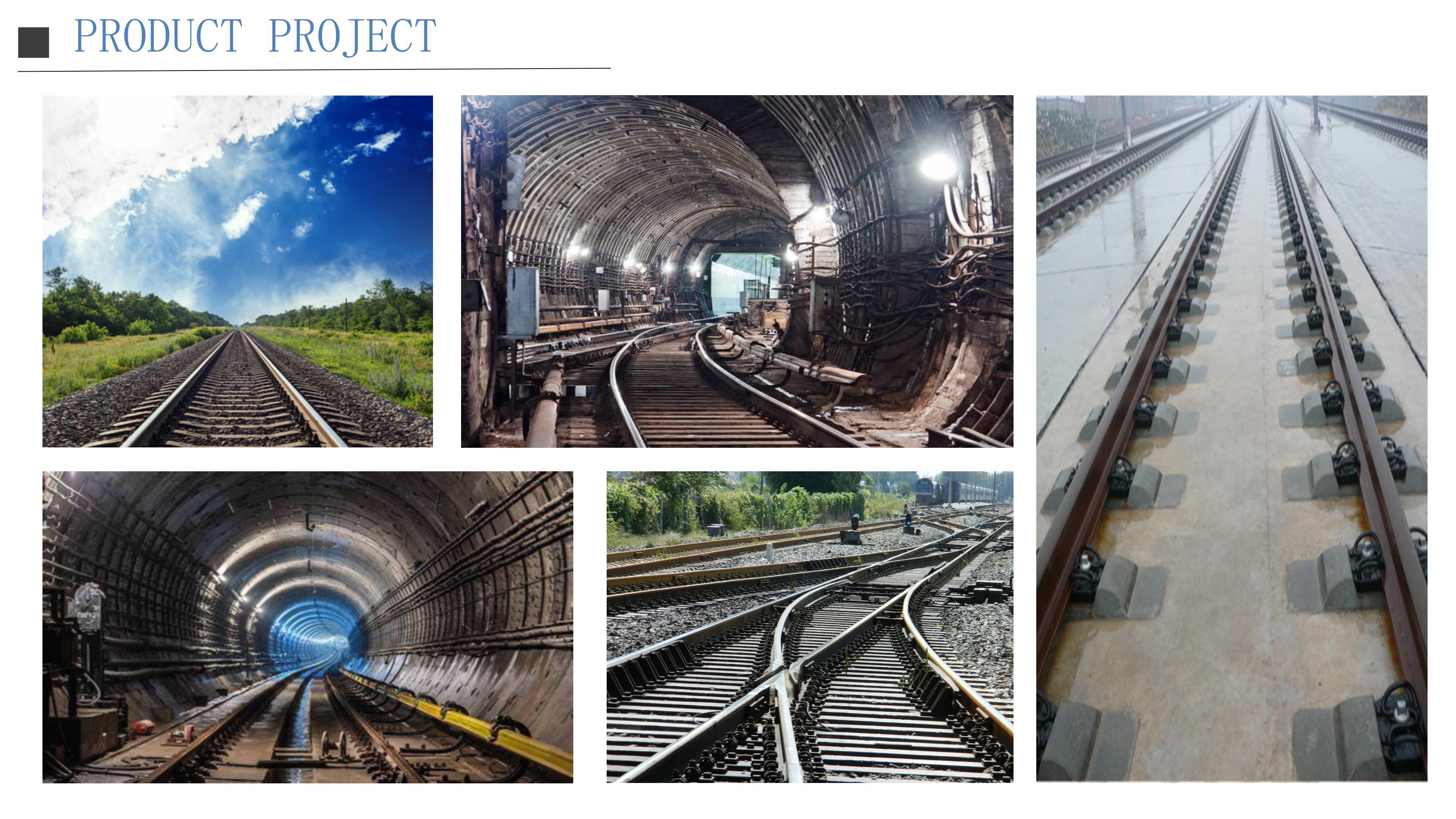

MORERO

Khamphani ea rona'lithane tse 13,800 tsaseporo sa tereneLi-romello tse rometsoeng United States li ile tsa romeloa Koung ea Tianjin ka nako e le 'ngoe. Mosebetsi oa kaho o ile oa phethoa ka katleho ka hore terene ea ho qetela e behoe butle-butle moleng oa terene. Li-romello tsena li hlahisitsoe moleng oa tlhahiso oa lefats'e oa fektheri ea rona ea literene le libalaka, ho sebelisoa maemo a tekheniki a holimo le a thata ka ho fetisisa lefatšeng.

Bakeng sa tlhahisoleseling e batsi ka lihlahisoa tsa terene, ka kopo ikopanye le rona!

WeChat: +86 13652091506

Mohala: +86 13652091506

Imeile:[email protected]

KOPO

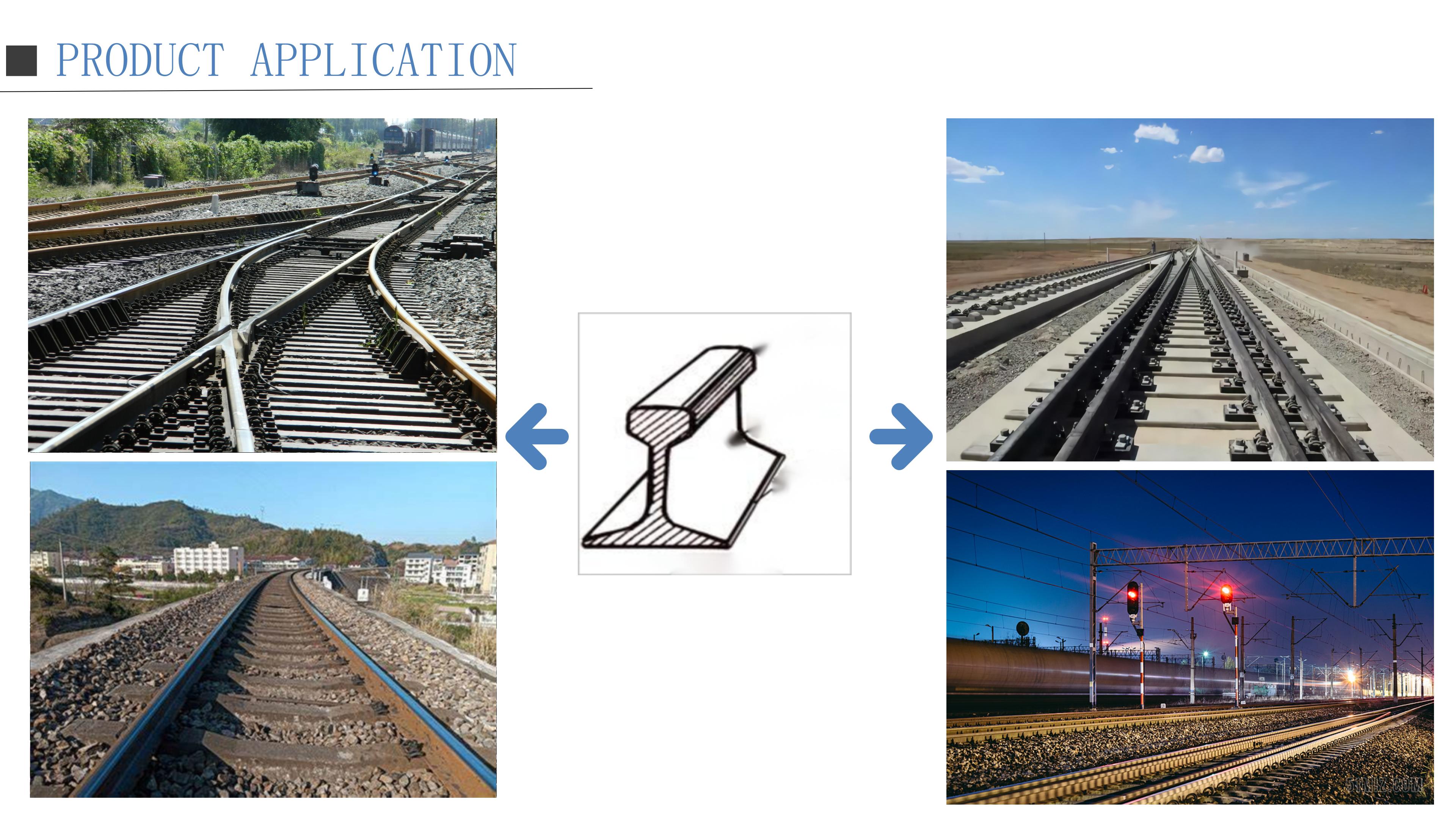

Tšepe ea tereneke oona feela mokhoa oa lipalangoang tsa terene o kopanang le mabili a terene. O jara mojaro oa axle le mojaro o ka thoko oa mabili a terene. Ka nako e ts'oanang, o tataisa tataiso ea mabili ho pholletsa le moeli o ka holimo ho netefatsa botsitso le polokeho ea terene.

HO PHAKISA LE HO ROMELA

Mehato ea tšireletso ea polokeho

1. Apara lisebelisoa tsa tšireletso tse kang lihelmete tsa tšireletso, lieta tsa tšireletso le liatlana.

2. Haeba o hloka ho sebetsa libakeng tse kotsi tse kang libaka tse phahameng kapa mekoting e tebileng, o tlameha ho roala mabanta a tšireletso le liropo tsa tšireletso.

3. Ela hloko boima, boholo le setsi sa boima ba terene, 'me u thibele ka tieo mekhoa e kotsi e kang ho jara boima bo feteletseng, ho tšela meeli le ho matha mabone a mafubelu.

4. Sebaka sa mosebetsi se lokela ho ba se hlakileng, bokaholimo ba tsela bo lokela ho ba boreledi, 'me lisebelisoa tse tsitsitseng li lokela ho tiea le ho tšepahala.

5. Ha ho tsamaiswa literene, ho lokela ho sebelisoa lisebelisoa tsa ho tsamaisa tse entsoeng ka mechini ka hohle kamoo ho ka khonehang ho qoba ho tsamaiswa ka letsoho.

Khetho ea lisebelisoa

1. Khetha lisebelisoa tse loketseng tsa ho phahamisa, tse kang likerene, likerene, jj., ho latela litlhoko tsa mesebetsi ea ho sebetsana le tsona. Ela hloko bokhoni ba mojaro bo lekantsoeng ba lisebelisoa 'me u fumane liparamente tse kang bophahamo ba ho phahamisa le lintlha tsa ho emisoa.

2. Lipalangoang tsa terene li ka sebelisa lisebelisoa le mekhoa e fapaneng joalo ka literoli, likereine, liforoko kapa ho hula ka letsoho. Ho khetha lisebelisoa le mekhoa e loketseng ho ka ntlafatsa katleho ea mosebetsi le ho fokotsa matla a basebetsi.

Tsebo ea ts'ebetso

1. Pele o tsamaisa liporo, hloekisa sebaka sa mosebetsi pele. Etsa bonnete ba hore bokaholimo ba tsela bo hloekile, bo boreleli, bo omme ebile ha bo na lithōle, lehlohlojane, likoti le lithōle tse ling.

2. Pele o tsamaisa literene, o lokela ho hlahloba boemo ba ts'ebetso le ts'ireletso ea lisebelisoa tsa ho phahamisa le lisebelisoa tsa ho tsamaisa. Hlahloba boemo ba bokaholimo le matla a ts'ebetso ea mabili, li-brake, lihokelo, lithapo tsa ho phahamisa, li-hangers le likarolo tse ling.

3. Ha ho tsamaisoa liporo, ho lokela ho qojoa maqhutsu le likotsi ka hohle kamoo ho ka khonehang. Li lokela ho phahamisoa hantle, li tsamaisoe hantle, 'me li behoe hantle.

4. Nakong ea ts'ebetso ea ho tsamaisa literene, ela hloko tikoloho e potolohileng le litšitiso, 'me u nke mehato ea polokeho le mehato ea ho qoba ka nako ho netefatsa ts'ebetso e sireletsehileng.

5. Literene li lokela ho jarisoa le ho tšoaroa ho latela bolelele le boima. Bakeng sa literene tse telele haholo le tse boima haholo, li lokela ho tsamaisoa ka likarolo kapa ho sebelisoe lisebelisoa tse loketseng tsa lipalangoang tsa katoloso.

6. Nakong ea ts'ebetso ea ho tsamaisa literene, ela hloko kalafo ea literene khahlanong le ho bola ho qoba tšenyo kapa ho tsofala holim'a seporo.

Lintho tse ka holimo ke tsona tse lokelang ho elwa hloko ha ho kenngwa kapa ho tsamaiswa diporo. Mehato ena ya ho thibela dikotsi e ka fokotsa dikotsi le dikotsi nakong ya tsamaiso ya dipalangwang mme ya netefatsa polokeho le bokgoni ba dipalangwang.

MATLA A K'hamphani

E entsoe Chaena, tšebeletso ea boemo ba pele, boleng bo holimo, e tsebahala lefatšeng ka bophara

1. Phello ea sekala: Khamphani ea rona e na le ketane e kholo ea phepelo le fektheri e kholo ea tšepe, e fihlelang liphello tse kholo lipalangoang le theko, 'me e fetoha k'hamphani ea tšepe e kopanyang tlhahiso le lits'ebeletso.

2. Mefutafuta ya dihlahiswa: Mefutafuta ya dihlahiswa, tshepe efe kapa efe eo o e batlang e ka rekwa ho rona, haholo-holo e sebetsanang le meaho ya tshepe, di-rails tsa tshepe, di-sheet pile tsa tshepe, di-bracket tsa photovoltaic, tshepe ya kanale, di-coil tsa tshepe tsa silicon le dihlahiswa tse ding, e leng se etsang hore e tenyetsehe haholoanyane. Khetha mofuta wa sehlahiswa o lakatsehang ho fihlela ditlhoko tse fapaneng.

3. Phepelo e tsitsitseng: Ho ba le mohala o tsitsitseng oa tlhahiso le ketane ea phepelo ho ka fana ka phepelo e tšepahalang haholoanyane. Sena se bohlokoa haholo ho bareki ba hlokang tšepe e ngata.

4. Tšusumetso ea lets'oao: E na le tšusumetso e phahameng ea lets'oao le 'maraka o moholo

5. Tšebeletso: Khamphani e kholo ea tšepe e kopanyang mokhoa oa ho iketsetsa, lipalangoang le tlhahiso

6. Tlholisano ea theko: theko e utloahalang

*Romella imeile ho[email protected]ho fumana khotheishene bakeng sa merero ea hau

KETO EA BAREKI

LBH

1. Nka fumana khotheishene joang ho tsoa ho uena?

O ka re siela molaetsa, 'me re tla araba molaetsa o mong le o mong ka nako.

2. Na o tla isa thepa ka nako?

E, re tšepisa ho fana ka lihlahisoa tsa boleng bo holimo le ho li tlisa ka nako. Botšepehi ke molao-motheo oa k'hamphani ea rona.

3.Na nka fumana disampole pele ke odara?

E, ehlile. Hangata disampole tsa rona ha di lefellwe, re ka di hlahisa ka disampole tsa hao kapa ka ditshwantsho tsa botekgeniki.

4. Lipehelo tsa hau tsa tefo ke life?

Nako ea rona ea tefo e tloaelehileng ke depositi ea 30%, 'me karolo e setseng khahlanong le B/L. EXW, FOB, CFR, CIF.

5. Na o amohela tlhahlobo ea motho oa boraro?

E, ruri rea amohela.

6. Re tšepa khamphani ea hau joang?

Re ikhethile khoebong ea tšepe ka lilemo tse ngata re le mofani oa khauta, ntlo-kholo e profinseng ea Tianjin, re amohelehile ho etsa lipatlisiso ka litsela life kapa life, ka mekhoa eohle.